Description

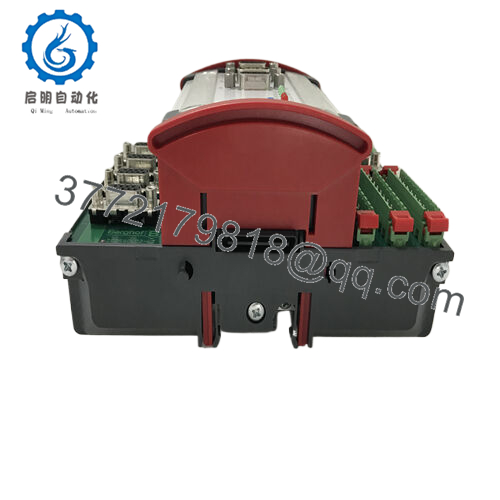

The C1CPU-4S-07 is a compact industrial control module designed by BERGHOF, widely used in automation systems that demand robust data acquisition, signal processing, and control capabilities. This module targets automation engineers and system integrators who need a reliable, high-performance programmable logic controller (PLC) core for controlling machinery and industrial processes. It finds application in automated manufacturing lines, process plants, and embedded system frameworks, where versatile communication and rapid response times ensure operational efficiency and safety.

Equipped with 16 digital inputs and 16 digital outputs, the C1CPU-4S-07 supports complex control tasks with precise timing and logic execution. It operates on a 24 V DC power supply and includes 512 KB of RAM along with 1 MB of flash memory for program storage, making it suitable for medium-level automation projects that require real-time multitasking. The controller’s architecture is panel-mount designed for rugged industrial environments. Its operating temperature range spans from -25°C to +60°C, allowing it to function reliably in various industrial contexts.

- C1CPU-4S-07

In control system architectures, the C1CPU-4S-07 integrates via standardized interfaces such as RS-232 and RS-485, permitting versatile and flexible connectivity to peripheral devices and communication networks. The module is designed with CANbus communication channels for distributed control applications, enhancing networking capabilities across multiple nodes in large automation systems. It features fail-safe mechanisms and internal data backup in flash memory, helping maintain process stability during power interruptions and system faults.

Technically, the C1CPU-4S-07 balances compact size with high functionality. It supports high-speed I/O response times and has an internal current limitation and thermal protection on output channels to enhance durability. Its configuration and diagnostic features include optical status LEDs on the front panel and comprehensive software tools provided by BERGHOF for programming and monitoring. The device complies with IEC and VDE safety and operational standards, making it suitable for applications where safety and reliability are paramount.

| Parameter | Value |

|---|---|

| Model | C1CPU-4S-07 |

| Brand | BERGHOF |

| Product Type | Compact PLC Controller Module |

| Digital Inputs | 16 |

| Digital Outputs | 16 |

| Memory | 512 KB RAM, 1 MB Flash |

| Power Supply | 24 V DC |

| Operating Temperature | -25°C to +60°C |

| Mounting | Panel mount |

| Communication Interfaces | RS-232, RS-485, CANbus |

| Safety Features | Fail-safe outputs, flash memory backup |

| Dimensions | Panel-mount form factor |

Related Modules:

- C1DI-16S-07 – Digital input module compatible for expanding input capabilities in BERGHOF systems.

- C1DO-16S-07 – Digital output complement to expand output control alongside the C1CPU-4S-07.

- C1AI-8S-07 – Analog input module often integrated for sensor signal processing near the CPU module.

- C1AO-8S-07 – Analog output module providing precise actuator control in distributed automation setups.

- C1CANW-01 – CANbus communication interface for network expansion with C1CPU-4S-07.

Installation and Maintenance:

When installing the C1CPU-4S-07, ensure it is mounted securely within an industrial control panel that provides adequate ventilation and protects against dust and moisture. Power supply lines should conform to the specified 24 V DC and maintain stable voltage within the tolerance range (18 V to 32 V) for consistent operation. Grounding and shielding are critical to prevent electromagnetic interference on communication lines such as RS-485 and CANbus. Regular inspection of wiring terminals and connectors is advised to prevent signal loss or intermittent faults.

Maintenance includes monitoring the status LED indicators for early warning of faults or communication issues. It is recommended to periodically back up configuration and application programs from the internal flash memory and update firmware as available from BERGHOF to maintain cybersecurity and system performance. Testing functional inputs and outputs during scheduled downtimes ensures operational continuity and mitigates unplanned failures.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626