Description

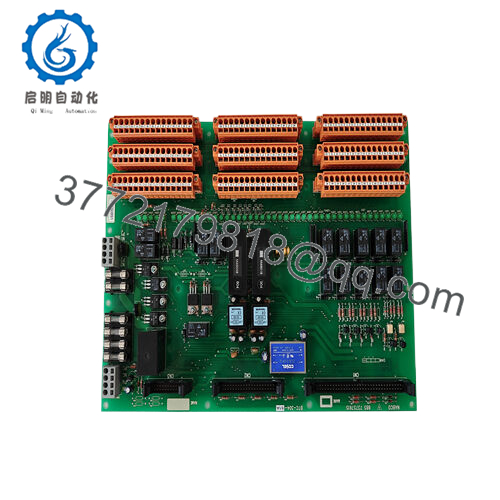

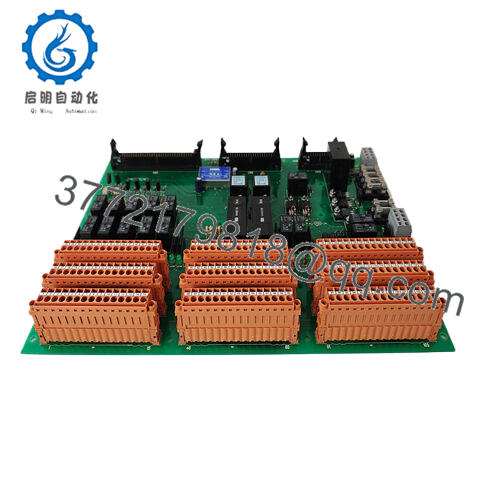

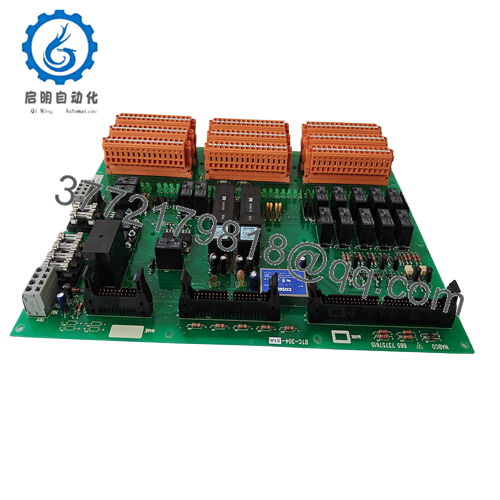

Product Model: BTC-304-51A

Product Brand: Nabtesco

Product Series: BTC-304 / BTC Controller Series

Product Features:

- High-performance thruster / motion control module / PCB board

- Supports multi-axis control, interpolation, tool / coordinate logic

- Onboard PLC logic, I/O support, error diagnostics

- Rugged design for industrial / marine / automation use

Product Role & System Fit

The BTC-304-51A functions as a central control or motion regulation module in systems requiring precise axis management, thrust control, or servo coordination. In many installations, it acts as the logic board converting high-level commands into control signals for motors, actuators, or thrusters.

In a marine or automation environment, for instance, the BTC-304-51A might interface between PLCs or supervisory systems and the drive hardware, ensuring that thrust, rotation speed, or orientation changes are executed precisely. Because of its modular PCB nature, it is often embedded in control cabinets, assemblies, or as part of a larger automation rack.

Compatibility with multiple I/O and PLC logic functions allows it to serve not just motion but control and safety functions. It fits into architectures where motion and logic must be co-located for real-time behavior, such as robotics, vessel thrusters, or industrial automation platforms.

- BTC-304-51A

Applications & Industry Context

The BTC-304-51A sees use across several demanding domains:

- Marine / Ship Automation / Thruster Control — As suggested by “thruster controller” references, it is suited for controlling propulsion or lateral thrusters in vessels, ROVs, or other maritime systems.

- Robotics & Automation — For robotics that require nested motion axes or thrust-like motors, the module can deliver deterministic control with built-in logic.

- Machine Tools / CNC Systems — Some listings of BTC-304 cards reference support for axes interpolation, coordinate systems, and tool logic akin to CNC controllers.

- Retrofit / Spare Module Markets — Many vendors list BTC-304-51A as a replacement PCB card for legacy systems (marine, industrial control) because original modules fail or need servicing.

Because of the module’s complexity, it is most often installed by system integrators, OEMs, or marine automation suppliers familiar with the control logic, firmware updating, and field I/O wiring.

Technical Features & Benefits

While full official specs are scarce, supplier listings and functional descriptions indicate these key capabilities and strengths for BTC-304-51A:

- Multi-Axis & Interpolation

The board supports multiple coordinated axes. Listings claim up to 5 control axes, with both linear and circular interpolation supported. - Built-in PLC / Logic Engine

It provides a two-level PLC program functionality for triggering logic, branching, and sequencing, in addition to motion functions. - Onboard I/O

Base I/O capabilities include ~48 inputs and ~38 outputs, with optional expansion boards for additional I/O and analog outputs. - Axis Commands & Coordinate Systems

The module supports coordinate transformations (workpiece, local, system), G-code style commands such as rapid positioning, circular interpolation, diameter/ radius commands and tool offsets. - Diagnostics & Error Handling

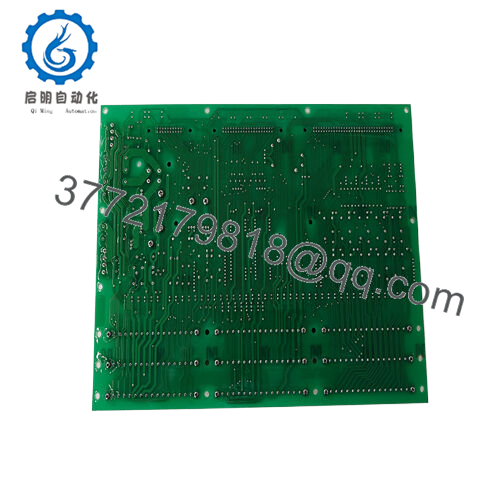

Fault detection for I/O issues, motion errors, overtravel, etc., helps increase system reliability and maintainability. - Modular / Card Format

Being a PCB / board card product, it can be replaced, repaired, or embedded in custom frames. Several vendors list it as a “PCB CARD.” - Industrial Operating Conditions

Built for industrial / marine environments, with attention to thermal stability, vibration resilience, and rugged electronics.

Together, these features make BTC-304-51A attractive when you need a compact, powerful control board that blends motion, logic, and I/O interfacing in one module.

Technical Specifications

Below is a synthesized table based on available source claims (treat this as draft — verify with official documentation):

| Specification | Description / Claimed Value |

|---|---|

| Model | BTC-304-51A (part of BTC-304 family) |

| Manufacturer / Brand | Nabtesco |

| Max Control Axes | 5 axes (coordinated) |

| I/O (Base) | 48 inputs / 38 outputs |

| Expandable I/O Options | External IOL modules (e.g. 24 in /16 out, analog outputs) |

| Interpolation | Linear, circular, cylindrical |

| Coordinate Systems | Workpiece, local, system (G54–G59) |

| PLC Logic | Dual-level PLC program with up to ~5,000 steps, 8 ms refresh cycle |

| Motion Commands | G0, G1, G2, G3, tool offsets, etc. |

| Power / Supply | Likely 24 V DC input (some listings) |

| Mounting / Format | PCB card / board form, module replacement style |

| Operating Environment | Industrial / marine grade, designed for control cabinets |

| Use / Status | Often sold in used / refurbished condition |

| Special Features | Tool setting (fixed / reference / auto), coordinate recording, diagnostic logic |

Installation & Maintenance Insights

Here are practical tips and caveats when deploying or maintaining the BTC-304-51A:

- Match Wiring & Pinouts

Because it’s a PCB module replacement, you must ensure connector pin legends and I/O wiring map exactly to the original. Mis-wiring can damage the board or cause logic failures. - Firmware / Configuration Backup

Before removal, capture any configuration, motion profiles, I/O templates, and parameter databases. Most control boards store these in non-volatile memory; missing that data can lead to long re-setup times. - Environmental Controls

Install the module in a clean, cooled, and vibration-controlled cabinet. Ensure airflow, separation from power electronics, and proper grounding to minimize noise interference. - Diagnostic Commissioning

On first power-up, cycle each axis in no-load mode, validate I/O transitions, test limit switches, verify coordinate systems, and monitor for error flags. This ensures basic hardware functionality before connecting actual loads. - Redundancy / Spares

Given that many BTC-304-51A units are only available used or refurbished, maintain a spare identical board (same revision) to enable fast field replacement. - Periodic Checks

Monitor fault logs, check connectors and screws, inspect for signs of overheating, clean dust and debris, and ensure firmware stays current (if such updates exist for your platform). - Handling Used Modules

Because many modules on the market are used, it’s important to test them (e.g. verify I/O, motion functionality, insulation, board health) before installation. Request known-good test reports from suppliers whenever possible.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626