Description

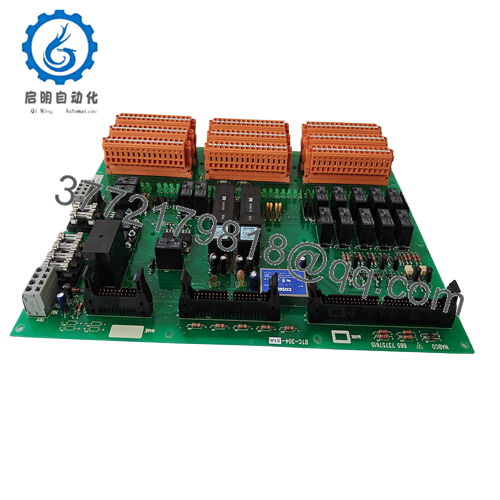

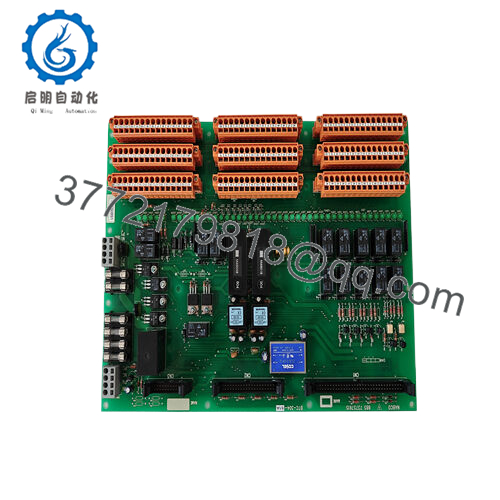

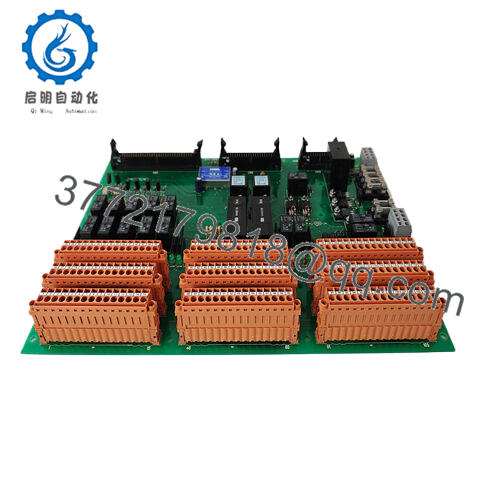

The BTC-304-51A functions as a multi-loop temperature controller, engineered to monitor and adjust thermal conditions in industrial processes using a combination of advanced sensing and control algorithms. It supports up to 4 independent temperature zones, each with configurable input types (thermocouple, RTD, or analog sensor) to match diverse process requirements. What sets it apart is its adaptive PID control logic, which automatically tunes parameters based on real-time process dynamics—eliminating the need for manual calibration and ensuring stable control even as load conditions change. The controller features a rugged 316 stainless steel housing with an IP67 rating, making it suitable for washdown environments and corrosive atmospheres, while its bright OLED display provides clear visibility of temperature data in dimly lit control rooms

BTC-304-51A

The BTC-304-51A integrates seamlessly with PLCs and SCADA systems via Modbus RTU/IP and Ethernet/IP, enabling remote monitoring and setpoint adjustments. It also includes built-in alarm functionality, triggering alerts for temperature excursions or sensor faults to prevent process deviations.

BTC-304-51A

Technical specifications:

Model Number BTC-304-51A

Brand NABTESCO

Type Multi-Loop Industrial Temperature Controller

Temperature Range -200°C to 1800°C (-328°F to 3272°F)

Control Loops 4 independent zones

Input Types Thermocouple (J, K, T, E, R, S, B), RTD (Pt100, Pt1000), 4-20mA

Output Signals 4x relay (5A), 2x analog (4-20mA)

Accuracy ±0.1°C (at 0-100°C reference range)

Operating Temp Range -10°C to 60°C (14°F to 140°F)

Mounting Style Panel mount (1/4 DIN cutout)

Dimensions 96mm x 96mm x 110mm (3.8″ x 3.8″ x 4.3″)

Weight 350g (12.3oz)

Protection Rating IP67 (front panel), IP20 (rear connections)

Compliance IEC 61010-1, CE, UL 508

Communication Modbus RTU/IP, Ethernet/IP

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

BTC-304-51A

Main features and advantages:

Choosing the BTC-304-51A delivers tangible benefits for process control and operational efficiency. Its 316 stainless steel construction resists corrosion from cleaning agents and industrial chemicals, making it ideal for pharmaceutical and food processing environments where hygiene is critical. The adaptive PID algorithm reduces temperature overshoot by up to 30% compared to conventional controllers, minimizing energy waste and ensuring faster stabilization after setpoint changes—critical for batch processes with tight cycle times. Engineers will appreciate the flexible input/output configuration, which eliminates the need for additional signal converters when integrating with legacy sensors or modern IoT-enabled devices. Most importantly, the BTC-304-51A’s multi-loop design reduces cabinet space requirements by consolidating control for four zones into a single unit, lowering hardware costs and simplifying system architecture.

BTC-304-51A

Application areas:

The BTC-304-51A excels in applications where precise, multi-zone temperature control is essential. In semiconductor manufacturing, it regulates thermal profiles in diffusion furnaces, ensuring uniform wafer heating to within ±0.5°C—critical for doping processes that determine chip performance. In plastic extrusion lines, it manages temperature across four barrel zones, preventing material degradation by maintaining consistent melt temperatures and reducing scrap rates by up to 15%. The controller also performs reliably in brewery fermentation tanks, where it monitors and adjusts temperatures in multiple vessels simultaneously, ensuring yeast activity remains optimal for consistent beer quality. In each case, the BTC-304-51A provides the thermal stability needed to maintain process integrity, directly contributing to higher yields and lower operational risk.

BTC-304-51A

Related products:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626