Description

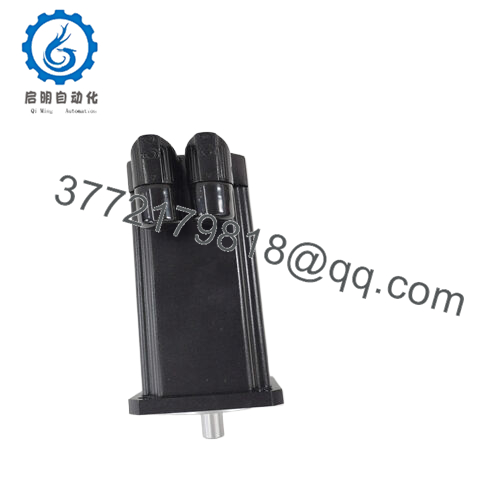

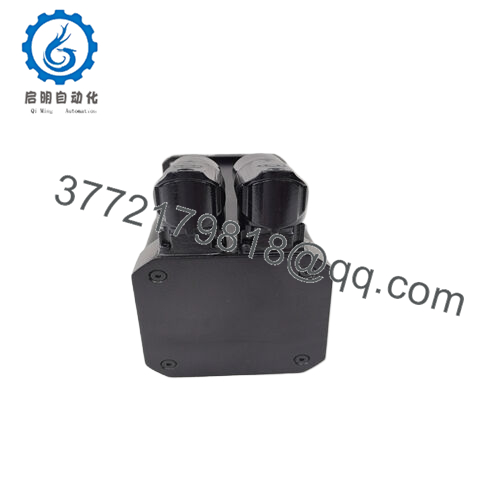

In the demanding landscape of industrial automation, where precise torque delivery and rapid acceleration are non-negotiable for dynamic applications like robotics or CNC spindles, engineers often grapple with motors that overheat under sustained loads, exhibit resonance in high-speed cycles, or demand extensive tuning to match drive amplifiers without compromising energy efficiency. The B&R 8LSA35,R0030D200-0 confronts these issues as a compact synchronous servo motor from the 8LS series, optimized for high-performance motion control with low rotor inertia to enable agile positioning and velocity profiling in process control systems. Imagine a packaging machine where pick-and-place axes must hit 3000 rpm bursts without vibration-induced skips—if the motor lacks thermal resilience or seamless encoder integration, you’d face misalignment errors, cycle time overruns, or premature wear that cascades into line stoppages. This motor proves essential in such high-reliability environments, where its self-cooling design and resolver feedback ensure I/O signal accuracy for closed-loop stability, supporting modular setups that scale without overhauling drive cabinets.

The B&R 8LSA35,R0030D200-0 is particularly indispensable in scenarios requiring balanced inertia ratios, such as material handling or winding processes, where its 0.3 Nm continuous torque at standstill delivers consistent holding power without auxiliary brakes. By incorporating a single-cable resolver interface, it minimizes wiring clutter and diagnostic blind spots common in multi-connector designs, aligning with broader automation strategies for predictive maintenance via Acopos drive families. In vibration-heavy or dust-laden plants, its IP64 sealing and F-class insulation prevent ingress-related faults, fostering system uptime that meets SIL 2 demands. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” resonate here—the B&R 8LSA35,R0030D200-0 empowers precise axis control, reducing the engineering effort for gain scheduling and enabling smoother synchronization in multi-axis networks where every quadrature pulse counts toward throughput.

- 8LSA35,R0030D200-0

The B&R 8LSA35,R0030D200-0 mounts via its 58 mm flange to machine frames or gearboxes, connecting to the automation stack through a SPEEDTEC angled swivel connector that routes power and resolver signals in a single hybrid cable, interfacing directly with B&R servo drives like the Acopos Px for torque or velocity mode operation. Positioned in the motion control layer, it converts three-phase AC inputs (up to 380-480 VAC) into rotary motion with a peak torque of 1.8 Nm, leveraging its low-inertia rotor (1.4 x 10^-4 kgm²) for acceleration up to 50,000 rad/s² while the self-cooling fins dissipate heat without forced air, ideal for enclosed cabinets. This integration supports backplane-free distributed architectures, where the resolver provides absolute positioning feedback at 2-pole resolution for homing routines, syncing with higher-level controllers via Sercos or Powerlink for coordinated multi-motor tasks.

In a practical configuration, the motor pairs with a drive amplifier to handle sinusoidal commutation, where the resolver’s sin/cos outputs (1 Vpp) feed error-corrected loops under 10 µs, and its thermal sensor embeds PTC data for overload protection, reportable via drive diagnostics. For example, in a textile loom, the B&R 8LSA35,R0030D200-0 might shuttle warp threads at variable speeds, ramping from 0 to 3000 rpm in 20 ms while monitoring winding temps to avert hotspots—all without resonance peaks thanks to its optimized pole-slot design. Its user-friendly swivel connector simplifies field swaps, and compatibility with B&R’s Automation Studio enables auto-tuning for inertia matching, cutting commissioning from hours to minutes. This efficient layering reduces cabling runs and enhances interoperability with safety modules, letting teams prioritize trajectory planning over mechanical tweaks in the overall process control ecosystem.

| Specification | Details |

|---|---|

| Model Number | 8LSA35,R0030D200-0 |

| Brand | B&R (Bernecker + Rainer Industrie) |

| Type | Synchronous Servo Motor (8LS Series) |

| Input Voltage | 380-480 VAC, 50/60 Hz |

| Operating Temp Range | 0 to +40°C (self-cooling) |

| Mounting Style | Flange (58 mm, B5 standard) |

| Dimensions | 170 mm (L) x 80 mm (D) |

| Weight | 2.1 kg |

| Interface/Bus | SPEEDTEC swivel connector, resolver (Hi-Res 2-pole) |

| Compliance | CE, UL, RoHS, IP64 |

| Supported Protocols | Sercos III, EtherCAT (via drive) |

| Typical Power Draw | 0.5 kW (continuous) |

Opting for the B&R 8LSA35,R0030D200-0 instills a motion foundation engineered for cyclic rigor, where its low-inertia profile ensures long-term performance by minimizing settling times that accumulate wear in repetitive profiles, allowing axes to track commands with <0.1° overshoot even under 80% load swings. In real-world runs, this means pickers in electronics assembly maintain micron-level placement without dither, curbing rejects and extending drive life through reduced current demands—crucial for processes where precision ties directly to quality gates or throughput quotas.

The motor’s single-cable resolver also streamlines diagnostics, as integrated feedback cuts signal noise that skews tuning, easing engineering overhead in multi-vendor plants and enabling remote health checks via B&R tools for vibration trends. Maintenance efficiency follows: PTC-embedded windings flag temps proactively, with bearing swaps (standard ball type) clocking under an hour using basic pullers, aligning with protocols for quarterly alignments that forestall failures. For operations chasing agility in tight spaces, the B&R 8LSA35,R0030D200-0 elevates servos from power-hungry components to efficient collaborators, bolstering synchronization and energy savings without mandatory overhauls.

In semiconductor wafer handling, the B&R 8LSA35,R0030D200-0 actuates vacuum grippers, its low-inertia ramping cleanly in cleanroom vacuums to ensure high reliability for process control—critical system uptime persists through 3000 rpm sprints without particulate shake-off in contamination-sensitive flows.

Printing presses deploy the B&R 8LSA35,R0030D200-0 for color cylinder sync, leveraging resolver fidelity amid ink mists and 50 Hz vibes; its self-cooling sustains process control accuracy, registering sheets at ±0.05 mm without thermal droop in high-duty cycles.

Pharmaceutical tablet presses harness the B&R 8LSA35,R0030D200-0 for die rotation, interfacing Acopos drives in sterile, humid bays—its IP64 seal and torque consistency uphold high reliability, dosing powders uniformly for compliant batches.

8LSA35,R0030D100-0 – Similar torque but straight connector for fixed installations.

8LSA45,R0050D200-0 – Higher-torque variant (0.5 Nm) for heavier loads in same frame.

8LSA25,R0020D200-0 – Lower-power (0.2 Nm) option for lighter axes.

8LVM35,E0030D200-0 – EnDat encoder model for absolute positioning upgrades.

8LSA35B,R0030D200-0 – Brake-equipped version for vertical holding applications.

8LSA56,R0100D200-0 – Larger frame (1.0 Nm) for expanded inertia matching.

8LVA23,R0030D200-0 – Linear variant for direct-drive alternatives.

Before commissioning the B&R 8LSA35,R0030D200-0, align its 58 mm flange to your mount with 0.01 mm concentricity using a dial indicator to avoid eccentricity vibes, and verify resolver cable shielding continuity under 1 ohm to nix quadrature errors—test with a 1 Vpp signal generator at 10 kHz. Confirm drive compatibility (Acopos Px series) via Automation Studio, setting velocity limits to 3000 rpm, and measure ambient airflow over fins to stay below 40°C rise; for IP64, inspect swivel seal o-rings pre-torque at 2 Nm. Baseline torque with a dynamometer at 0.3 Nm continuous to calibrate gains.

Sustaining the B&R 8LSA35,R0030D200-0 starts with monthly PTC resistance checks via drive diagnostics—aim for <1500 ohms at idle to catch winding shorts early, especially in humid zones where moisture creeps. Quarterly, lubricate bearings per SKF specs if hours exceed 20,000, using a grease gun at 10% capacity, and scan for hotspot patterns with an IR thermometer under load. Annually, during PM windows, demagnetize the rotor if fields drift >5% via a pulse tool, but limit to bench: no live spins. These IEC 61800-5.2 steps keep rotors responsive without disassembly marathons.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626