Description

The B&R 5AP1120.0702-000 servo drive serves as the core of servo motor control, converting control commands from the automation controller into precise electrical signals to drive motor motion. It can seamlessly integrate with B&R’s automation platform and backplane system, utilizing high-speed communication protocols such as POWERLINK to achieve real-time data exchange and synchronization with other components in the automation stack. Whether connected to programmable logic controllers (PLCs), PC based control systems, or specific motion control devices, 5AP1120.0702-000 can execute complex motion trajectories with extremely high precision.

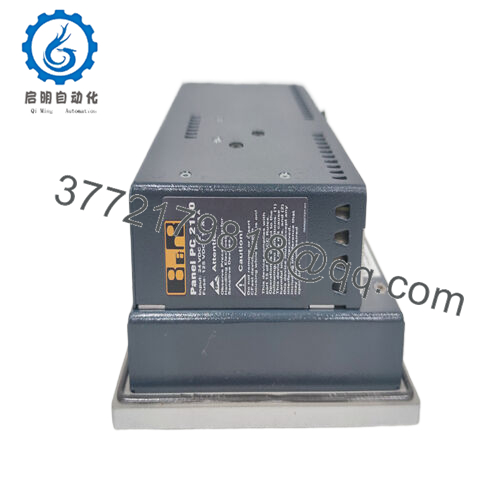

5AP1120.0702-000

This servo drive adopts advanced control algorithms to optimize motor performance, ensuring smooth acceleration, deceleration, and positioning. It also has built-in diagnostic functions that can continuously monitor the operating status of the drive, including motor current, temperature, and encoder feedback. Once a malfunction occurs, the comprehensive diagnostic function of the drive can quickly identify the root cause of the problem, enabling engineers to perform targeted troubleshooting and minimize downtime. In addition, B&R 5AP1120.0702-000 supports various feedback mechanisms such as incremental and absolute, and can be flexibly configured according to specific application requirements.

5AP1120.0702-000

Technical specifications:

Model 5AP1120.0702-000

Brand B&R

Type servo drive

Input voltage 3 x 400-480 VAC

Output power 1.2 kW

Continuous output current of 2.8 A

Control mode position, speed, torque

Communication interface POWERLINK, Ethernet

Working temperature range: 0 ° C -55 ° C

Installation method: Panel installation

Dimensions 177mm x 150mm x 145mm

Weight 2.5 kg

Certification CE, UL

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

5AP1120.0702-000

Main features and advantages:

This servo drive is designed for high performance and reliability, enabling manufacturers to achieve higher levels of accuracy and productivity in motion control applications. Its advanced control algorithm and fast response time ensure smooth and precise motion, reduce the possibility of errors, and improve product quality.

The built-in diagnostic and monitoring functions of 5AP1120.0702-000 significantly reduce maintenance work and costs. Engineers do not need to rely on manual inspection and time-consuming troubleshooting, but can use the self diagnostic function of the drive to quickly identify and solve problems. This not only minimizes downtime to the greatest extent possible, but also extends the service life of servo drives and connecting components. In addition, its modular design and compatibility with various B&R automation products make it easy to integrate into existing systems or upgrade for future expansion, providing long-term flexibility and cost-effectiveness.

5AP1120.0702-000

Application areas:

In the field of automobile manufacturing, it plays a crucial role in robot assembly processes, such as precise positioning of robot arms in tasks such as welding, painting, and component installation. Its high-speed and high-precision capabilities ensure stable and accurate motion, allowing manufacturers to increase production speed while maintaining strict quality standards.

In the packaging industry, this servo drive is used to control the movement of packaging machines, ensuring precise filling, sealing, and labeling operations. Its ability to adapt to different product sizes and shapes makes it possible to quickly switch between production batches, reducing setup time and improving overall equipment efficiency. In addition, in the semiconductor manufacturing industry, there are extremely high precision requirements for processes such as wafer processing and chip placement. B&R 5AP1120.0702-000 provides the stability and accuracy needed to meet the demanding demands of this highly specialized field.

5AP1120.0702-000

Related products:

B&R 5AP1130.0702-000- Output power of 3.0 kW, suitable for higher demand motion control applications

B&R 5AP1110.0702-000- Output power of 0.75 kW, suitable for small automation projects

B&R 5AP1120.002-000- Provides enhanced communication capabilities with additional interface options for easy integration with complex automation systems

B&R 5AP1120.0702-001- Improved thermal management variant designed for continuous operation in high temperature environments

B&R 5AP1120.0703-000- Equipped with advanced safety features, suitable for safety critical applications such as collaborative robots

Installation and maintenance:

Before installing the B&R 5AP1120.0702-000 servo drive, it is essential to verify that the input voltage (3 x 400-480 VAC) matches the available power supply in your facility. Ensure proper ventilation around the drive to prevent overheating, as operating temperature can significantly affect its performance and lifespan. In addition, carefully check the wiring connections, including power cables, motor cables, and encoder cables, to ensure that they are securely connected and terminated correctly. It is crucial to configure the parameters of the drive according to the specific requirements of the servo motor and application, such as motor type, encoder resolution, and control mode.

For continuous maintenance, the status indicator lights and diagnostic information of the drive should be regularly monitored to detect any potential issues as early as possible. It is recommended to regularly inspect cables and connectors to ensure they are in good condition and undamaged. Regularly clean the exterior of the drive to remove dust and debris, which may affect its heat dissipation efficiency. Although B&R 5AP1120.0702-000 is designed for reliable operation, conducting annual performance checks (including testing drive control accuracy and response time) can help identify and address potential performance degradation issues over time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626