Description

In the rugged domain of industrial automation, where distributed I/O networks must withstand electrical noise, expansion constraints, and the push for scalable control without centralized bottlenecks, engineers often encounter limitations like limited slave connectivity, signal attenuation over distances, or the need for hot-pluggable modules that don’t disrupt ongoing processes. The B&R 2EX302.5 addresses these head-on as a versatile I/O expansion module from the System 2010 series, designed to extend baseplate functionality by linking up to two expansion slaves for enhanced digital and analog handling in process control setups. Envision a conveyor sorting facility where additional sensors for position detection or actuators for diverters require seamless integration—if the expansion interface falters under load or demands extensive rewiring, you’d risk desynchronized signals, fault cascades, or production halts that amplify costs in 24/7 operations. This module becomes crucial in such high-reliability scenarios, where its robust interfaces ensure precise I/O signal distribution, supporting modular growth that aligns with legacy B&R architectures without overhauling the entire bus.

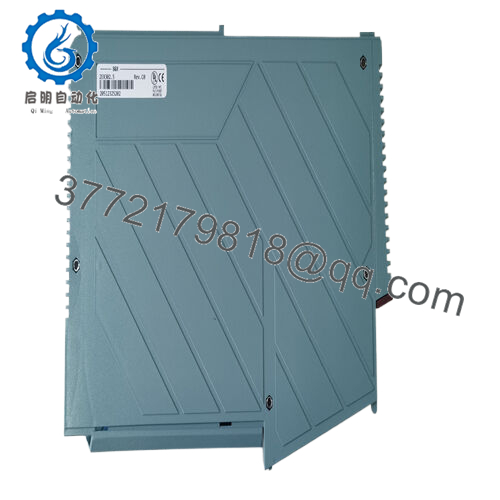

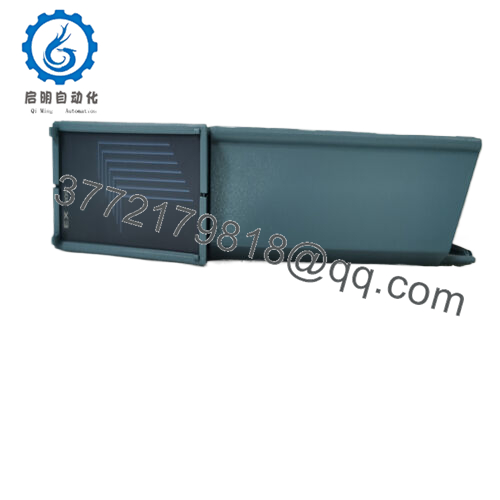

- 2EX302.5

The B&R 2EX302.5 is especially vital in environments craving flexible backplane extensions, such as material handling or assembly lines, where its compatibility with BP200, BP201, and BP210 base plates allows daisy-chaining of slaves for up to 32 additional I/O points without performance degradation. By facilitating 1m or 2m expansion cables, it mitigates common issues like voltage drops or EMI-induced errors that plague longer runs, enabling engineers to achieve system stability in compact enclosures. In vibration-intensive or dust-heavy plants, its low-profile design and keyed connectors prevent accidental mismatches, streamlining diagnostics through integrated status monitoring. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” underscore its value—the B&R 2EX302.5 empowers distributed control, reducing the engineering lift for field expansions and fostering uninterrupted data flow in setups where every connected slave contributes to operational resilience.

The B&R 2EX302.5 integrates into the System 2010 backplane ecosystem, mounting directly onto compatible base plates to form the expansion hub, where it bridges the primary controller—such as a 2CP200 CPU module—to downstream slaves via dedicated interfaces that support both digital and analog peripherals. Positioned in the I/O distribution layer of the automation stack, it handles signal routing for up to two slaves, using shielded expansion cables to maintain integrity over short distances while drawing power from the base plate’s 24 VDC rail, ensuring isolated paths that prevent ground loops in multi-drop configurations. This setup interacts with the bus controller for polling and command dissemination, where the module’s keyed slots enable hot-plugging without power cycling, ideal for live maintenance in continuous processes.

In a standard deployment, the B&R 2EX302.5 pairs with slaves like digital output cards to extend actuator control, relaying commands from the CPU while providing feedback loops for error detection via onboard diagnostics, compatible with B&R’s 3.5″ or 5.7″ HMIs for remote oversight. It supports protocols inherent to System 2010, such as proprietary bus comms for real-time synchronization, and its compact form factor fits neatly into DIN-rail assemblies, reducing enclosure depth by up to 20% compared to bulkier alternatives. For instance, in a palletizing cell, the B&R 2EX302.5 might connect slave modules for gripper sensors, buffering signals to filter transients and alerting on disconnects—all while adhering to CE and UL standards for EMI immunity. This thoughtful architecture minimizes cable clutter and boosts interoperability with legacy expansions, allowing focus on logic refinement rather than connectivity hurdles in the broader process control framework.

| Specification | Details |

|---|---|

| Model Number | 2EX302.5 |

| Brand | B&R (Bernecker + Rainer Industrie-Elektronik) |

| Type | I/O Expansion Module (System 2010 Series) |

| Input Voltage | 24 VDC (from base plate) |

| Operating Temp Range | 0 to +50°C |

| Mounting Style | Base plate-mounted (BP200/201/210) |

| Dimensions | 285mm (H) x 40mm (W) x 185mm (D) |

| Weight | 0.8 kg |

| Interface/Bus | Expansion interfaces (2x slaves), keyed connectors |

| Compliance | CE, UL, RoHS |

| Supported Protocols | System 2010 bus (proprietary) |

| Typical Power Draw | 3 W (max) |

Incorporating the B&R 2EX302.5 provides a scalable extension engineered for persistent loads, where its dual-slave capacity ensures long-term performance by accommodating incremental I/O growth without scan delays, letting distributed nodes track commands with sub-ms latency even as the network expands to 32 points. In the field, this means sorters maintaining alignment across added diverters without jitter, curbing misroutes and stabilizing energy profiles—essential for workflows where expansion ties directly to capacity ramps or fault resilience.

The module’s keyed hot-plug also eases deployment strains, as mismatch-proof slots cut installation errors by halves in crowded panels, trimming engineering hours for field teams and enabling phased add-ons without downtime risks. Maintenance refines naturally: status indicators flag slave faults early, with connector inspections yielding quick fixes under 15 minutes, syncing with routines for quarterly verifications that extend MTBF beyond 100,000 hours. For sites evolving legacy systems, the B&R 2EX302.5 shifts expansions from logistical drags to fluid enhancements, bolstering modularity and efficiency without footprint penalties.

In logistics fulfillment centers, the B&R 2EX302.5 links slave modules for barcode scanners and pushers, its interfaces thriving in dusty, high-throughput aisles to deliver high reliability for process control—critical system uptime holds through extended chains that prevent parcel pileups in peak sorting.

Food packaging lines deploy the B&R 2EX302.5 for filler diverters, routing signals in steamy, washdown bays where keyed mounts fend off moisture; its low draw sustains process control accuracy, sequencing packs without drip-induced shorts in sanitary runs.

Discrete assembly cells harness the B&R 2EX302.5 for tool changers, interfacing slaves amid oily mists and jolts—its compact bus extension upholds high reliability, syncing grippers for defect-free joins in variable-pitch operations.

2EX200.50-1 – Base expansion slave module for initial I/O add-ons with the 2EX302.5.

2CP200 – CPU controller companion for primary logic in System 2010 expansions.

2EX100.50-1 – Bus controller variant for hybrid digital/analog slave pairings.

2PS425.9 – Power supply module to ensure stable 24 VDC feeds for 2EX302.5 chains.

2NC102.6 – Compact network coupler for remote slave extensions beyond 2m cables.

BP210 – Enhanced base plate for mounting multiple 2EX302.5 in stacked configs.

2EX302.60 – Upgraded expansion with four slave ports for denser I/O needs.

Before integrating the B&R 2EX302.5, verify base plate alignment—BP200/201/210—with a continuity tester for backplane pins under 0.5 ohms to avoid signal ghosts, and measure cable lengths to 1-2m max for attenuation below 5%. Confirm 24 VDC ripple under 100 mV via scope to prevent slave resets, and torque keyed connectors to 1.5 Nm for vibration grip; in dusty locales, apply dielectric grease to seals pre-seating. Baseline slave polling with B&R diagnostics software, targeting <2 ms response across two interfaces.

Tending the B&R 2EX302.5 begins with monthly indicator sweeps for link greens, using a DMM to affirm isolation >1 MΩ between buses—reseat if dips occur, a 5-minute enclosure-open task in de-energized states. Quarterly, inspect expansion cables for frays in flex zones, swapping if continuity exceeds 1 ohm, and log fault counts via software for patterns. Annually, during system audits, simulate slave disconnects to validate hot-plug recovery under 100 ms, but offline: no live expansions. These IEC 61131-2 practices keep extensions eager without panel plunges.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626