Description

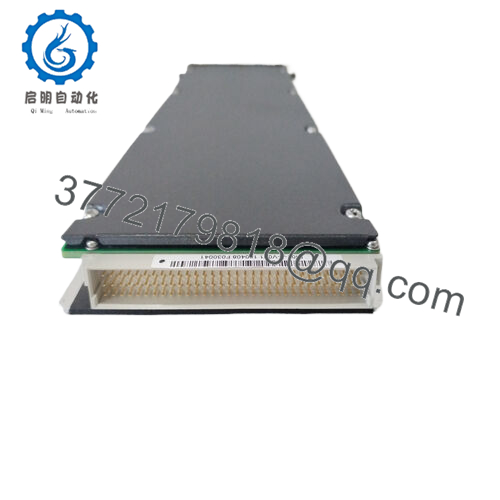

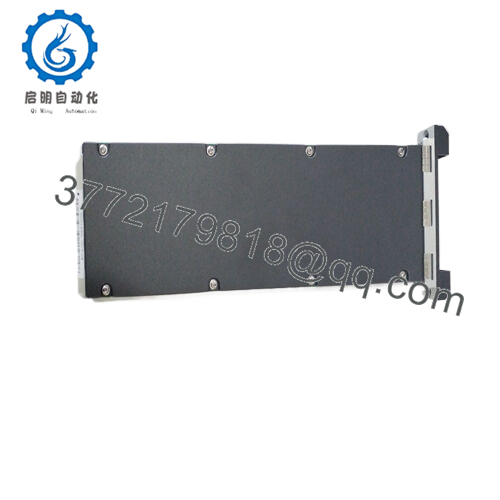

The BI01 functions as a multi-purpose terminal block, engineered to terminate and secure electrical wires in control panels and junction boxes. It features 12 individual terminals arranged in a compact, single-row design, accommodating wire sizes from 22AWG (0.34mm²) to 10AWG (6mm²)—making it suitable for both low-voltage signal lines and moderate-power circuits. What sets it apart is its dual-connection mechanism: it accepts both screw and spring-clamp terminations, providing flexibility for different installation preferences and wire types. The terminal block is constructed with a high-temperature resistant housing that withstands industrial heat and chemical exposure, while its integrated barrier design prevents cross-contact between terminals, reducing the risk of short circuits.

BI01

The BI01 mounts easily on standard 35mm DIN rails, integrating seamlessly into existing cabinet setups, and includes clear marking slots for easy wire identification—simplifying troubleshooting and maintenance.

BI01

Technical specifications:

Model Number BI01

Type Industrial Terminal Block

Wire Size Range 22AWG (0.34mm²) to 10AWG (6mm²)

Number of Terminals 12 (single-row)

Connection Type Screw and spring-clamp combination

Rated Voltage 600V AC/DC

Rated Current 20A per terminal

Operating Temp Range -40°C to 85°C (-40°F to 185°F)

Mounting Style 35mm DIN rail

Dimensions 80mm x 50mm x 30mm (3.1″ x 2.0″ x 1.2″)

Weight 120g (4.2oz)

Protection Features Flame-retardant housing (UL94 V0), terminal barriers

Compliance EN 60947-7-1, CE, UL 1059

Material Polyamide 6.6 housing, copper alloy terminals

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

BI01

Main features and advantages:

Choosing theBI01 offers significant benefits for industrial systems. Its rugged polyamide housing, rated UL94 V0 for flame resistance, ensures safety in case of electrical faults, while its wide operating temperature range allows reliable performance in extreme environments—from freezing warehouses to hot factory floors. The dual-connection design reduces installation time by accommodating both rigid and flexible wires without the need for additional adapters, cutting wiring efforts by up to 30% compared to single-mechanism terminal blocks. Engineers will appreciate the terminal barriers, which minimize the risk of accidental short circuits during maintenance, and the compact size, which saves valuable DIN rail space in crowded control panels. Most importantly, the BI01’s secure terminations resist vibration-induced loosening, a common issue in machinery applications, reducing unplanned downtime and repair costs.

Application areas:

TheBI01excels in diverse industrial scenarios where reliable connections are key. In packaging machinery, it secures sensor and actuator wires, ensuring consistent communication between photoelectric sensors and control systems—critical for maintaining precise packaging cycles. In agricultural processing facilities, it withstands exposure to dust and cleaning chemicals while connecting motor control circuits, ensuring conveyors and sorting equipment operate without interruption. The terminal block also performs well in renewable energy systems, such as wind turbine control cabinets, where it connects temperature and vibration sensors, ensuring data flows reliably to monitoring systems. In each application, the BI01 provides the stable connections needed to keep operations running smoothly, directly contributing to higher productivity.

Related products:

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626