Description

In the pulse-racing world of industrial automation, where fire and gas detection systems must deliver split-second alerts to avert catastrophes in confined or hazardous spaces, the common bottleneck is fragmented monitoring—especially in multi-zone setups where smoke or vapor plumes can spread undetected across cargo holds or process bays. Consider a container vessel navigating rough seas or a bulk carrier laden with volatile cargoes: aspirating smoke detectors in up to 48 remote holds need centralized oversight, but without a robust repeater interface, operators face delayed responses, obscured status readouts, or manual overrides that falter under vibration, humidity, or power glitches. Standard panels might cover basics, but they often lack the intuitive local controls and visual cues required for high-reliability environments compliant with SOLAS or IMO standards, where integration into broader safety instrumented systems (SIS) demands seamless diagnostics and fault-tolerant operation to protect lives, cargo, and hull integrity.

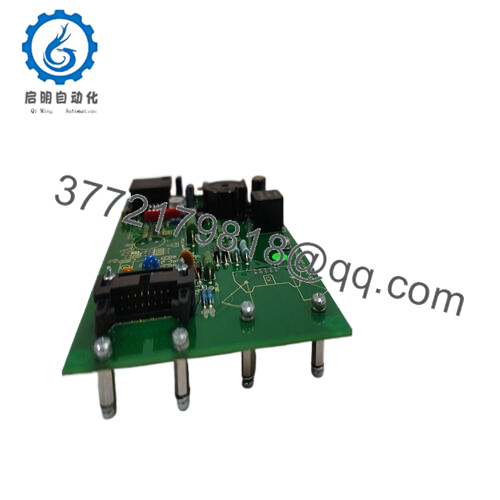

The Safetec BG02.510 addresses this head-on as a dedicated control module for repeater panels in the SDS-48 smoke detection system, providing the tactile, at-a-glance command center that empowers quick decisions without tethering crews to the main console. Engineered for marine and industrial process control, it mounts discreetly behind the repeater’s front cover, housing an LC-display for real-time zone status, multi-color LEDs for alarm prioritization, and responsive push-buttons for silencing, resetting, or acknowledging faults—ensuring I/O signals from distributed detectors translate into actionable insights amid electromagnetic noise or saltwater corrosion. In scenarios like offshore loading terminals or chemical tankers, where high-reliability monitoring is non-negotiable, the Safetec BG02.510 shines, enabling modular integration that extends SDS-48 coverage without rewiring overhauls, while its flame-retardant housing (UL 94V-0 rated) upholds SIL-equivalent integrity for those edge-of-hull deployments.

For engineers retrofitting legacy fire panels or scaling aspirating networks, the Safetec BG02.510 cuts through operational fog by consolidating repeater functions into a compact, user-centric unit—eliminating the guesswork of scattered indicators and fostering the system stability that keeps watch continuous, even when the main panel is decks away. It’s the reliable sentinel that aligns field-level alerts with crew reflexes, turning potential blind spots into fortified vigilance in the unforgiving cadence of industrial automation.

The Safetec BG02.510 operates as the nerve center within the SDS-48 ecosystem, interfacing directly with the repeater panel’s backplane to aggregate and display data from up to 48 aspirating channels via a proprietary bus that ensures low-latency polling under 500 ms. At its core, the LC-display renders zone-specific smoke density trends or fault codes in alphanumeric format, while the LED array—typically 4-8 indicators per hold—pulses in red for active alarms, yellow for pre-warnings, and green for nominal states, all driven by embedded logic that debounces inputs from remote BG02.820 detector modules to filter transient dust or humidity spikes. Push-buttons trigger discrete outputs for system-wide actions, like horn muting or test modes, serialized back to the central SDS-48 controller for logging and SCADA uplink, supporting redundancy through dual-relay contacts that failover to a secondary repeater in under 2 seconds.

- BG02.510

Positioned at the user-interface layer of your fire and gas (F&G) stack, the Safetec BG02.510 bridges field sensors to higher-tier automation platforms, compatible with Modbus RTU for DCS handoffs or dry contacts for tie-ins to HIMA-style SIS gateways—though optimized for standalone marine ops, it adapts to hybrid industrial setups via optional RS485 extensions. Diagnostics are front-and-center: self-test routines cycle the display and LEDs on power-up, flagging internal faults like backlight failures via error codes, while event buffers store up to 100 incidents for download via USB or Ethernet ports on the host panel. Mount it flush in weatherproof enclosures (IP54 rated) near bridge stations or engine rooms, where its low-profile design minimizes panel depth, and pair multiples for segmented views in large-hold configurations. This intuitive footprint means no steep learning curves—just straightforward commissioning that syncs with existing SDS-48 firmware, letting you layer in process control overlays without disrupting aspirator flows or airflow validations.

In essence, the Safetec BG02.510 streamlines the F&G architecture by embedding operator ergonomics into the hardware, ensuring your detection loops close with clarity and speed, whether in rolling swells or steady-state refineries.

| Specification | Details |

|---|---|

| Model Number | BG02.510 |

| Brand | Safetec |

| Type | Control Module for Repeater Panel |

| Input Voltage | 24 VDC (18-32 V) |

| Operating Temp Range | -25 °C to +70 °C |

| Mounting Style | Panel-Mount (behind front cover) |

| Dimensions | 182 x 105 x 38 mm (H x W x D) |

| Weight | 0.27 kg |

| Interface/Bus | Proprietary SDS-48 Bus, RS485 |

| Compliance | UL 94V-0, CE, IMO/SOLAS |

| Supported Protocols | Modbus RTU, Dry Contacts |

| Typical Power Draw | 3 W |

Selecting the Safetec BG02.510 brings a layer of operational fluency to your SDS-48 deployments, where its ergonomic interface turns raw detector data into instinctive responses, fostering the reliability that keeps crews ahead of escalating risks. The LC-display and LED synergy delivers long-term performance by surfacing subtle pre-alarms—like airflow deviations—before they trigger full evacuations, minimizing false positives that erode trust in high-stakes shifts and extending system MTBF beyond 150,000 hours through vibration-dampened internals that shrug off marine pounding.

Maintenance efficiency gets a boost too: button-life diagnostics preempt sticky actuators via usage counters, while LED self-checks integrate with panel logs to flag dimming early, reducing engineering overhead from full teardowns to quick visual confirms—ideal for vessels where dry-dock windows are razor-thin. The Safetec BG02.510 ensures performance consistency across thermal extremes, holding display refresh at 1 Hz even in fogged enclosures, so your F&G loops stay synchronized with process rhythms, whether sampling hold vents or stack gases. Integration eases the load further; its bus-agnostic ports mesh with incumbent alarms sans adapters, cutting retrofit timelines and enabling modular add-ons like remote annunciators without recertifying the stack.

Engineered for endurance in the grit of real automation, it anticipates upgrades—firmware flashes preserve configs across SDS revisions—yielding a module that safeguards not just compliance but crew confidence, dialing down incident potentials while amplifying uptime in environments where every alert counts.

In marine cargo shipping, the Safetec BG02.510 fronts repeater panels on bulk carriers, channeling SDS-48 inputs from hold aspirators in humid, salt-lashed process control setups, where its push-button resets ensure critical system uptime amid rolling swells, preempting cargo fires in SOLAS-mandated smoke monitoring.

Offshore supply vessels deploy the Safetec BG02.510 for engine-room duplicates, displaying airflow alerts from turbine bays under high-vibration loads, supporting fast data cycles in F&G environments that demand intuitive overrides for nonstop resupply ops without halting drills.

Chemical tanker fleets leverage it in bridge consoles, aggregating detector statuses across 48 tanks in corrosive vapor zones, with the Safetec BG02.510‘s LED hierarchy aiding continuous uptime by prioritizing leaks in IMO-compliant networks where delayed acknowledgments could ignite payloads.

BG02.500 – Primary panel variant for main SDS-48 consoles, with expanded event buffering for central logging hubs.

BG02.501 – Enhanced control field module for high-traffic repeaters, adding haptic feedback buttons for gloved ops.

BG02.502 – Ruggedized sibling with extended I/O for auxiliary horn relays in noisy machinery spaces.

BG02.820 – Detector connection add-on for 8-channel expansions, pairing with BG02.510 for denser hold coverage.

SDS02.300 – Compatible repeater enclosure for flush-mount integrations in compact wheelhouse designs.

SDS02.301 – Wall-mount repeater host, ideal for retrofitting BG02.510 into legacy alarm panels.

BG02.820-8 – Multi-line detector module alternative for airflow-heavy applications like vent stacks.

SDS-48 CPU – Core processor upgrade path for firmware-aligned enhancements beyond basic controls.

Before fitting the Safetec BG02.510 into your repeater, cross-check compatibility with SDS-48 firmware—versions post-2.0 avoid handshake lags—and inspect the panel cutout for 182 x 105 mm tolerances to prevent alignment strains on the bus connector. Verify input polarity with a DMM on the 24 VDC feed, targeting 18-32 V stability to sidestep brownouts from generator dips, and secure the mounting screws to 1 Nm torque for vibration hold-downs in excess of 5g. If tying into RS485 extensions, terminate segments at 120 ohms to curb reflections, and allocate 20 mm rear depth for cabling without pinch points that could abrade insulation over time.

Once commissioned, upkeep centers on practical, interval-based rituals that preserve responsiveness without undue downtime. Monthly, cycle the push-buttons through a full test sequence—observe LED transitions for uniform brightness—and pull the event buffer via the host USB to scan for debounce anomalies, addressing with a soft reset if counts exceed 5%. Biannually, in dry conditions, swab the display lens and button apertures with microfiber and isopropyl to clear salt residue, powered off to reset latches, and validate LC contrast under low-light sims to confirm readability thresholds. For proof-testing per SOLAS Chapter II-2, inject mock alarms quarterly and time acknowledgments under 3 seconds, documenting via panel printouts for flag-state audits. In high-humidity berths, consider silica packs nearby to buffer condensation. This calibrated routine, attuned to marine realities, sustains the Safetec BG02.510‘s acuity, heading off degradations before they compromise your detection edge.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626