Description

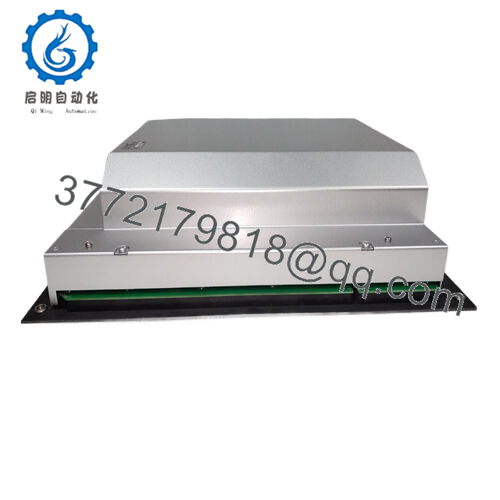

Product Model: BF15015.1 353522-04

Product Brand: Heidenhain

Product Series: BF 150 series

Product Features:

- 15-inch XGA color flat-panel display for CNC / HMI systems

- Resolution of 1024 × 768 pixels, with integrated soft keys

- 24 V DC power supply, approximately 45 W consumption

- Compatible with Heidenhain iTNC and related control units

Product Role & System Fit

The BF15015.1 353522-04 module is essentially the human interface component in many Heidenhain CNC control systems. Its primary role is as an operator display panel — showing machine status, coordinate readouts, program execution, alarms, soft key menus, etc. In other words, it’s not a logic controller or an I/O board; it’s the screen and control surface through which operators interact with the CNC.

In systems using the Heidenhain iTNC controllers, the BF 150 display is normally directly wired to the controller’s video and keyboard interface (often via LVDS or parallel lines). The module includes not just the LCD panel but also the front panel overlay, the soft-key matrix, status LEDs, and the supporting electronics to interface to the controller logic.

Because it is integrated so tightly with the control architecture, the BF15015.1 353522-04 must match not just electrical pinouts and supply voltages, but also firmware and front-panel key mappings. Replacing one from a different revision (e.g. 353522-03 vs 353522-04) may require matching the version or performing a front-panel reprog.

In many retrofit or repair situations, engineers swap out the BF 150 module as the go-to replacement when displays fail (backlight degradation, LCD defects, or front-panel key failures). It is a direct substitute in many iTNC-based systems, making it a critical modular spare in machine tool service inventories.

Applications & Industry Context

CNC machine tools — milling, turning, grinding — rely heavily on robust, precise operator displays. The BF15015.1 353522-04 is most commonly found in industrial machine shops, tool manufacturing, and precision industries where Heidenhain controllers are standard.

In use cases such as multi-axis milling machines or 5-axis machining, the operator uses the BF 150 panel continuously: adjusting coordinates, starting programs, setting zero offsets, and reacting to alarms. Its clarity and latency directly impact operator effectiveness.

Beyond machining, the BF 150 finds use wherever Heidenhain’s control systems are installed — for example, in milling centers in the aerospace, automotive, and mold/die manufacturing sectors. In large machine tool retrofit projects, swapping out aging CRT or older displays for the BF15015.1 353522-04 is a cost-effective route to modernizing the operator interface.

Because display failure (e.g. backlight burn out) is among the more common failure modes in CNC systems, maintaining spare BF 150 units is standard practice in machine tool shops with Heidenhain controls.

- BF15015.1 353522-04

Technical Features & Benefits

The BF15015.1 353522-04 module is modest in function but critical in usability. Its key features and benefits include:

1. 15″ XGA Resolution Display

With a 1024 × 768 pixel screen, it presents machine status, tool paths, and control menus clearly and legibly.

Soft-key lines above and beside the screen provide interactive menu control, reducing reliance on external keyboards.

2. Soft-Key Support and Interface Logic

It includes eight horizontal soft keys and six vertical soft keys (or function keys), with row switching capabilities for dynamic menu contexts.

The soft key logic is integrated on the display board, simplifying the wiring to the controller.

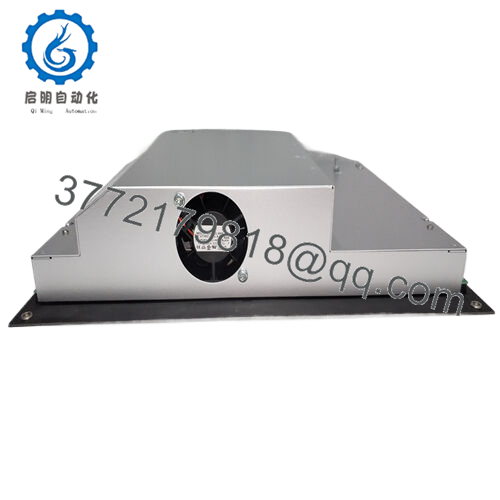

3. Power and Form Factor

It accepts 24 V DC input and consumes approximately 45 W in typical use.

The front bezel is designed to match the original panel dimensions for easy insertion or replacement in machine control enclosures.

4. Compatible with Existing Systems

It is intended as a direct replacement for earlier BF 150 units (353522-01, 02, 03).

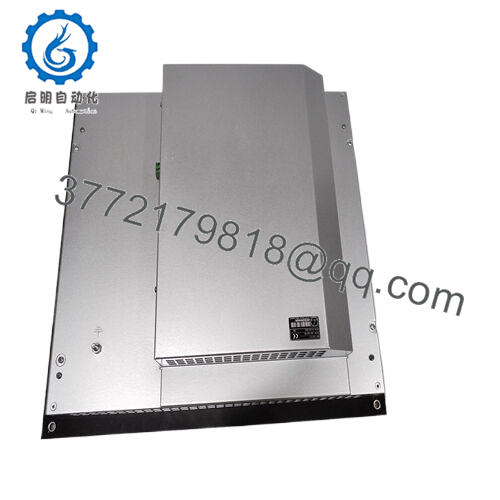

Video interface is via a Sub-D / LVDS connector (often a 44-pin connector) matching Heidenhain controller output formats.

5. Rough-Environment Robustness

While not extremely ruggedized (it’s a display), it is built for industrial control environs. The frontplate and enclosure help protect from dust and light mechanical damage. The operating temperature range is often specified around –10 to +55 °C in retrofit units.

6. Retrograde Replacement Support

Because many machine tool platforms have long lifecycles, the BF150 module is often stocked as a long-term spare. Its compatibility with multiple revision IDs means fewer variant SKUs and simplified spares logistics.

Together, these features make the BF15015.1 353522-04 a dependable, serviceable operator interface for Heidenhain-based CNC systems.

Technical Specifications

| Specification | Description |

|---|---|

| Model / ID | BF15015.1 353522-04 |

| Display Type | 15″ color flat-panel LCD / XGA (1024×768) |

| Soft Keys | 8 horizontal soft keys, 6 vertical soft keys |

| Power Supply | 24 V DC nominal |

| Power Consumption | ≈ 45 W |

| Video Interface | LVDS / Sub-D 44-pin (controller interface) |

| Front Panel Dimensions | ~400 × 350 mm (bezel) in replacement units |

| Operating Temperature | –10 °C to +55 °C (dependant on unit / install) |

| Certification / Usage | Designed for integration with Heidenhain CNC systems |

| Compatible Revisions | 353522-01 / -02 / -03 / -04 |

| Typical Applications | Machine tool HMI, CNC control display panel |

Installation & Maintenance Insights

Swapping or installing the BF15015.1 353522-04 requires attention to mechanical and electrical details:

- Power off and discharge before removing the old module. The 24 V DC wiring must be handled carefully.

- Note the connector pin assignments for both LVDS video and keyboard interface. The replacement must match exactly to avoid damaging the module or controller.

- Replace the front bezel and panel gasket if there is wear; sealing against dust ingress is important in shop-floor environments.

- After insertion, allow a warm-up period (a few minutes) for backlight stabilization. Then verify brightness, soft-key activation, and display contrast.

- Check that soft keys map correctly to functions. In some retrofits, firmware or front-panel reprogramming may be required if key order differs.

- Periodically check for backlight degradation: if brightness fades or uniformity shifts, replacement before failure is recommended to avoid operator downtime.

- Clean the display surface with recommended, non-abrasive cleaners; dust or grit can scratch LCD coatings.

As a practice, many machine shops keep one BF150 spare unit on hand, ready for immediate field swap to minimize downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626