Description

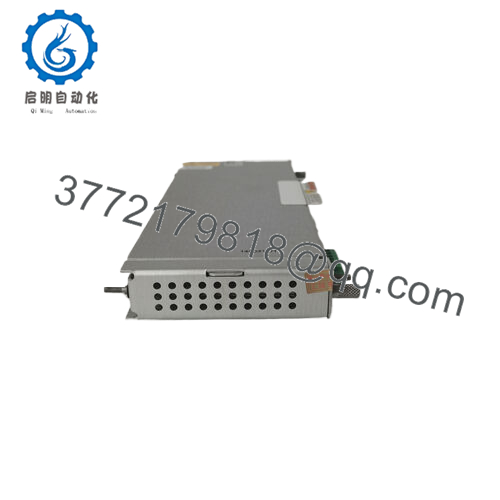

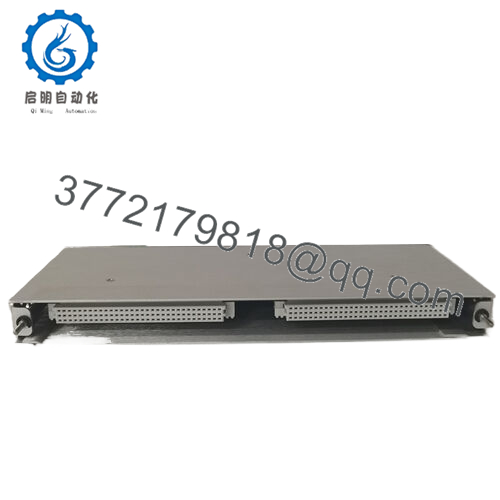

The BENTLY 146031-01 is a cornerstone component within the BENTLY monitoring system architecture. Installed within a compatible BENTLY rack, it acts as a central hub for data acquisition and pre – processing. Its primary function is to interface with a wide range of sensors, collect raw data from them, and then perform a series of operations to transform this data into a format suitable for further analysis and transmission.

146031-01

Equipped with advanced analog – to – digital conversion circuitry, it can handle various types of sensor signals. For example, it can accurately convert high – frequency vibration signals from accelerometers into digital values, as well as low – voltage DC signals from temperature sensors. The module also features built – in signal conditioning algorithms that filter out noise, compensate for signal attenuation, and normalize the data. This ensures that the data sent to the system’s backplane is of high quality and ready for processing by other components such as data acquisition units, controllers, and analytics software.

It supports a comprehensive suite of communication protocols commonly used in industrial sensors, including 4 – 20 mA current loops, 0 – 10 VDC voltage signals, and digital protocols like Modbus RTU and CANbus. This versatility makes it highly adaptable to different sensor types and brands, facilitating seamless integration in both new and existing monitoring systems. In the overall system, the 146031 – 01 collaborates closely with other BENTLY modules. It provides the necessary data input for real – time monitoring dashboards, alarm systems, and predictive maintenance algorithms. By working in tandem with these components, it helps maintain the integrity of the entire industrial monitoring infrastructure, ensuring that machinery operates at peak efficiency and reliability.

146031-01

Technical specifications:

Model Number 146031-01

Brand BENTLY

Type High – Performance Data Acquisition and Processing Module

Input Voltage 24V DC (from system power supply)

Operating Temp Range – 15°C to + 65°C (5°F to + 149°F)

Mounting Style Rack – Mounted (compatible with BENTLY racks)

Dimensions 160mm x 80mm x 210mm (WxHxD)

Weight 900g

Number of Input Channels 16 (expandable in certain configurations)

Supported Sensor Signals4 – 20 mA, 0 – 10 VDC, Modbus RTU, CANbus, etc.

Signal ConditioningAdvanced filtering, noise cancellation, normalization

Analog – to – Digital ConversionHigh – resolution, fast – sampling ADC

ComplianceCE, UL 61010 (suitable for industrial use)

Data ThroughputHigh – speed data transfer to system backplane, up to [X] Mbps

Typical Power Draw 10W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

146031-01

Main features and advantages:

146031-01

Application areas:

146031-01

Related products:

- BENTLY 146032 – 01: A higher – end version of the module with increased processing power and more advanced signal conditioning capabilities. It is suitable for applications that require handling of extremely complex sensor data or high – speed data acquisition, such as in high – tech manufacturing processes or research facilities.

- BENTLY 146030 – 01: A more basic data acquisition module with fewer input channels and less sophisticated processing features. It is designed for less demanding applications where cost is a primary consideration and the need for high – volume data processing or complex protocol support is not significant, like in small – scale industrial setups or simple machinery monitoring.

- Generic third – party data acquisition modules: Some third – party manufacturers offer products that can perform similar data acquisition and processing functions. However, they may lack the seamless integration, reliability, and technical support provided by BENTLY’s own modules. These third – party options can be considered in cases where specific customization requirements are not met by BENTLY’s standard offerings, but users should be aware of potential compatibility and support issues.

- BENTLY 146031 – 02: An updated version of the module with enhanced connectivity options, such as support for emerging industrial communication protocols. It is suitable for applications that are looking to future – proof their monitoring systems and take advantage of the latest technological advancements in industrial networking.

Installation and maintenance:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626