Description

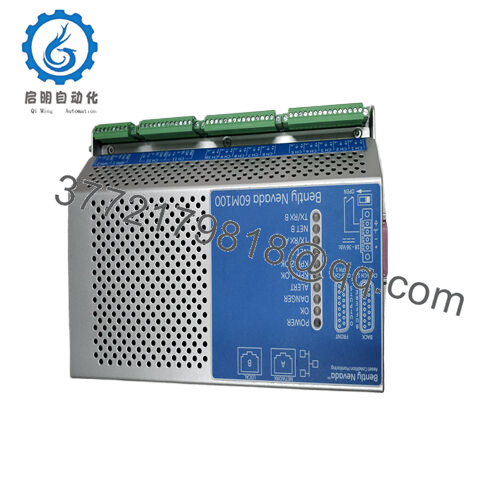

In the variable winds of renewable energy production, where turbine drivetrains endure relentless torque and thermal cycling that can mask gear wear or misalignment until a gearbox seizes mid-gust, engineers battle the opacity of intermittent faults that slash output and skyrocket repair logistics. Envision an offshore wind farm or a sprawling onshore array: blades spin at variable speeds, feeding erratic power to the grid, but without granular oversight of main bearings, tower sway, or rotor imbalances, you’re flying blind—relying on sporadic SCADA pings or post-failure teardowns that cost thousands per hour in lost generation. This opacity not only hampers process control but invites cascading risks under IEC 61400 standards, where undetected vibrations amplify to blade pitches gone awry or yaw drives straining. Enter the Bently Nevada 60M100-00, a dedicated wind turbine condition monitor that pierces this veil with continuous, state-aware diagnostics, transforming raw sensor streams into predictive alerts that preserve high reliability for I/O signals in harsh, remote setups.

The imperative for this level of vigilance intensifies in fleets chasing 99.9% availability, like hybrid solar-wind hybrids or repower projects, where a single tower’s downtime ripples across MW-scale contracts. From farm audits I’ve supported in gusty coastal zones, operators often contend with generic monitors that overload on broadband noise or ignore operational context—like low-wind idling masking rubs—leading to alert fatigue and deferred maintenance that balloons OPEX. The Bently Nevada 60M100-00 counters this by leveraging adaptive algorithms attuned to turbine states, flagging anomalies months ahead via integrated vibration, temperature, and speed channels, so you orchestrate crane lifts during lulls rather than emergencies. In the evolving domain of industrial automation for renewables, it stands as the sentinel for modular integration, where signal fidelity from accelerometers or encoders feeds fault-tolerant logic without the drag of false trips or custom filters.

At heart, the Bently Nevada 60M100-00 reorients monitoring from episodic checks to embedded intelligence, empowering data-driven decisions that extend asset life and align with net-zero mandates. It’s the tool that anticipates the unpredictable—salt spray corroding housings, thermal gradients warping shafts—delivering the operational foresight that keeps rotors turning and revenues steady in process control ecosystems built for endurance.

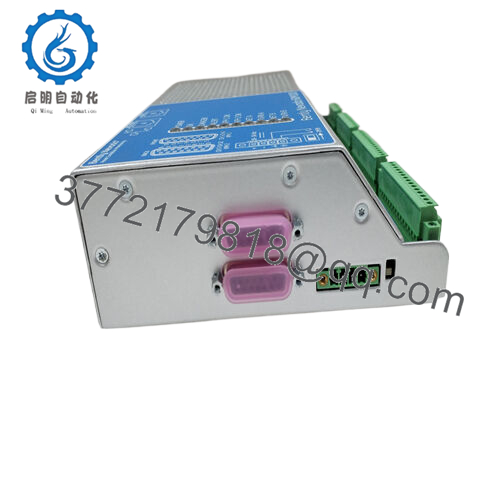

When outfitting a nacelle or hub for holistic drivetrain surveillance, the Bently Nevada 60M100-00 serves as the centralized processor in your condition monitoring stack, ingesting signals from up to 20 channels—accelerometers on gearboxes, RTDs for bearing temps, encoders for speed—via its front-end I/O ports, then applying FFT-based spectral analysis and order tracking to distill trends against baseline envelopes. It mounts via DIN rail in the turbine’s auxiliary cabinet, linking to the main controller over Modbus TCP or Ethernet/IP for seamless handoff to SCADA, while optional relay outputs trigger local shutdowns if thresholds breach—positioned as the mid-layer aggregator between field transducers and cloud historians, ensuring low-latency (<1s) updates even over 10km fiber runs.

In flow, it syncs with turbine PLCs to contextualize data—demodulating yaw rates during high-wind events or filtering idles for subtle rubs—while self-diagnostics poll channel health, alerting on cable faults via integrated LEDs or SNMP traps to minimize on-tower climbs. Redundancy embeds naturally: dual power inputs (18-36 VDC) with internal failover keep it alive through grid flickers, and its software-configurable alarms support voting schemes for critical paths like main shaft misalignment. No external gateways needed; it normalizes diverse protocols, feeding cleaned envelopes to asset management overlays for fleet-wide correlations—say, correlating tower sway across arrays to preempt foundation cracks.

60M100-00

60M100-00

60M100-00

This adaptability shines in distributed architectures, where it daisy-chains with Bently’s 3500 series for hybrid legacy upgrades or scales standalone for OEM integrations, its IP67-rated enclosure shrugging off -40°C gales. For commissioning, plug into System 1 software for baseline capture during commissioning spins, mapping spectra to operational bands. Far from a passive logger, the Bently Nevada 60M100-00 orchestrates proactive guardianship, weaving turbine dynamics into a responsive process control net that anticipates failures before they fracture the chain.

| Specification | Details |

|---|---|

| Model Number | 60M100-00 |

| Brand | Bently Nevada (Baker Hughes) |

| Type | Wind Turbine Condition Monitor |

| Input Voltage | 18-36 V DC |

| Operating Temp Range | -40°C to +80°C |

| Mounting Style | DIN Rail / Enclosure |

| Dimensions | 200 x 150 x 100 mm |

| Weight | 2.5 kg |

| Interface/Bus | Ethernet / Modbus TCP |

| Compliance | CE, IEC 61400, RoHS |

| Supported Protocols | Modbus TCP, Ethernet/IP, SNMP |

| Typical Power Draw | 15 W |

Incorporating the Bently Nevada 60M100-00 yields a cascade of predictive acuity that elevates turbine longevity, where state-tuned algorithms discern genuine threats from benign noise—consider isolating a gearbox mesh fault during partial loads, averting the multimillion-euro overhauls that idle strings for weeks and erode investor confidence. Engineered for the elemental fury of wind exposure, it upholds unwavering performance through conformal-coated boards and wide-temp optics, so your monitoring persists across seasons, delivering the granular spectra that refine maintenance scopes from blanket inspections to laser-focused interventions.

This system also streamlines operational cadence, its remote configurability via secure web interfaces slashing tower access needs by 70%, letting remote teams harvest trends for fleet optimizations rather than sifting false alarms—key in dispersed farms where logistics bite hard. In expansive renewable portfolios, it diminishes integration friction by emulating standard DCS I/O, so expansions fold in without protocol proxies or rebaselining, freeing engineering for yield algorithms over wiring wars. Field personnel gain from its intuitive dashboards, where color-coded envelopes build instinctive threat awareness, fostering cultures that treat anomalies as opportunities, not ordeals.

Moreover, the Bently Nevada 60M100-00 cultivates enduring economics, its early defect spotting—up to six months lead time—curtailing lost MWh that compound to seven figures annually, while enabling just-in-time spares that trim inventory bloat. The broader yield? Resilient grids from fewer curtailments, audit-ready logs for subsidy compliance, and the latitude to hybridize with solar for baseload stability—all propelled by a monitor that doesn’t merely observe the spin, but safeguards its sustainability.

In onshore wind arrays, the Bently Nevada 60M100-00 embeds in hub cabinets to track main rotor imbalances and yaw dynamics, enduring dust-laden winds to sustain critical system uptime via real-time speed-vibration correlations—indispensable for process control environments where sway-induced rubs could cascade to blade strikes. Its spectral resolution catches precursors amid variable RPMs, bolstering high reliability in farms spanning kilometers.

For offshore floating platforms, it’s vaulted in watertight enclosures monitoring tower sway and subsea bearings, thriving against saline sprays and 50m/s gusts to ensure continuous uptime, with Ethernet relays feeding platform SCADA for preemptive pitch adjustments. The Bently Nevada 60M100-00 excels in modular integration here, scaling per turbine without central overhauls.

In repowered legacy sites, the Bently Nevada 60M100-00 interfaces with upgraded gearboxes for internal bearing diagnostics, handling thermal cycles in retrofits to maintain fast data cycles—deployed in process control environments demanding IEC-compliant vigilance to maximize ROI on older towers.

60M100-01 – Enhanced variant with expanded channel capacity for denser sensor arrays in large-hub turbines.

3500/05 – Rack companion for hybrid land-based integrations blending wind with vibration suites.

1900/65A – Universal monitor alternative for non-wind rotating assets like hydro pumps.

60M100-10 – Software-upgraded model with AI-driven anomaly detection for fleet analytics.

3300/35 – Analog I/O module add-on for legacy signal bridging in 60M100-00 setups.

System 1 – Core software platform that configures and hosts data from the 60M100-00.

60M101-00 – Yaw-specific companion for specialized tower motion tracking in offshore apps.

Prior to nacelle-mounting the Bently Nevada 60M100-00, benchmark your sensor roster—accelerometers demand API 670-compatible cabling to curb noise, and sync Ethernet IPs with the turbine PLC via initial pings to forestall address clashes. Secure DIN fasteners to 2 Nm in vibration zones, then baseline during a low-wind spin-up; amber LEDs on power-up signal probe mismatches, so reseat term blocks before go-live. Enclosure integrity matters: seal glands against IP67 breaches in salty airs, and site it 200mm from heat vents to hold under 80°C peaks.

In rotation, biannual cable continuity tests at junctions detect sheath wear from blade flex—depower slices, ohm to ground, and log drifts exceeding 5%. Quarterly, pull spectral exports via System 1 for baseline drifts, simulating faults like rub tones to affirm alarm fidelity; persistent anomalies cue slice isolation for granular FFTs. Annual full-farm calibrations during dormant seasons—injecting known vibes—validate end-to-end chains without blade halts, while firmware aligns with Baker Hughes releases post-config export. These moorings, forged from farm forensics, keep the monitor’s edge honed, warding the subtle erosions that dull predictive power.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626