Description

Real-World Use & Application Scenarios

The Bently Nevada 3500/70M Reciprocating Impulse Velocity Monitor is integral to the protection and condition monitoring of reciprocating compressors, a vital asset in process industries such as oil and gas, petrochemicals, and power generation. It addresses the challenge of monitoring vibrations in compressor crankcases and crossheads, which is critical for early fault detection and continuous machine health assessment. By accurately measuring impulse and velocity signals, this module helps operators avoid costly failures, excessive downtime, and safety risks associated with mechanical vibration in reciprocating machinery. Its real-time data supports predictive maintenance strategies and ensures safer, uninterrupted plant operation.

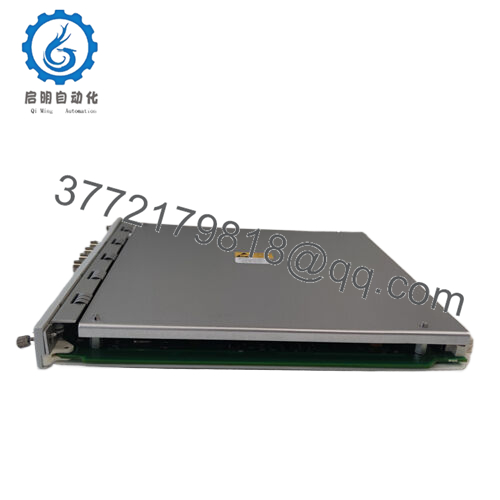

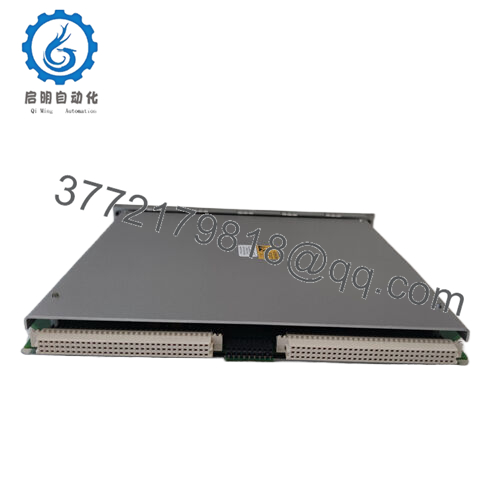

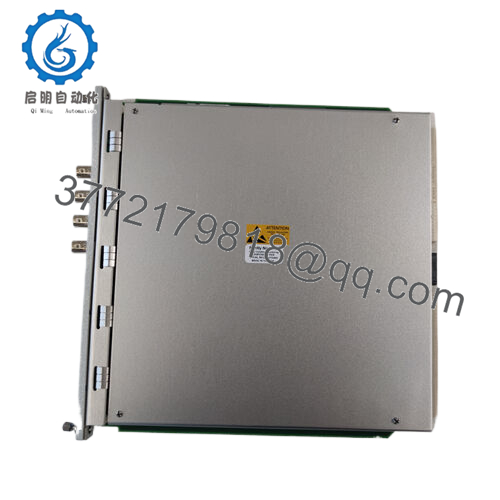

- 3500/70M

- 3500/70M

Product Introduction & Positioning

The Bently Nevada 3500/70M is a four-channel device designed to accept inputs from seismic transducers, processing vibration signals specifically tailored for reciprocating compressor monitoring. This module conditions signals to derive precise vibration measurements such as impulse acceleration, acceleration, and reciprocating velocity, providing comprehensive vibration analysis for each channel. The monitor is programmable through the 3500 Rack Configuration Software, allowing customization of alarm thresholds and delay settings to fit specific application needs. Positioned as a key element of the Bently Nevada 3500 Series machinery protection platform, the 3500/70M integrates seamlessly with other modules and plant control systems to enhance asset reliability and safety.

Key Technical Features & Functional Benefits

The 3500/70M accepts from one to four inputs including velocity and acceleration signals from seismic transducers such as Bently Nevada 330400, 330425, and Velomitor CT devices. Its signal conditioning circuits provide low noise and high fidelity, enabling accurate vibration measurements crucial for detecting compressor faults.

The device supports programmable alarm annunciation and shutdown functions based on custom thresholds, allowing operators to react promptly to abnormal vibration levels. Each channel can be configured individually or paired, offering flexibility in monitoring various vibration modes simultaneously. Power consumption is approximately 7.7 watts, facilitating energy-efficient operation during continuous monitoring.

Designed for harsh environments, the module withstands typical industrial temperature ranges (-30°C to +65°C) and humidity up to 95% non-condensing. The compact form factor allows efficient rack space utilization and easy integration into existing systems.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500/70M |

| Brand | Bently Nevada |

| Product Type | Reciprocating Impulse Velocity Monitor |

| Number of Channels | 4 |

| Supported Inputs | Velocity and acceleration signals |

| Power Consumption | Approximately 7.7 watts |

| Operating Temperature | -30°C to +65°C |

| Humidity Range | Up to 95% non-condensing |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 241.8 mm |

| Weight | Approximately 0.85 kg |

Related Modules or Compatible Units

3500/72 – Reciprocating Rod Position Monitor for rod position and rod drop detection.

3500/40M – Proximitor monitor module for vibration and position sensing.

3500/44M – Aeroderivative gas turbine vibration monitor.

3500/50 – Tachometer module for speed and acceleration monitoring.

3500/53 – Overspeed detection module enabling fast protective responses.

3500/60 – Temperature monitoring module supporting bearing and process temperatures.

3500/91M – Communication gateway for network integration of machinery data.

Installation Notes & Maintenance Best Practices

Installation of the 3500/70M requires secure mounting within Bently Nevada 3500 Series racks, ensuring proper connection of input seismic transducer signals and power. Adhere to grounding and shielding standards to minimize electromagnetic interference and maintain signal accuracy. Ensure ambient conditions within the specified temperature and humidity range during operation.

Routine maintenance should focus on monitoring status LEDs and alarm signals to detect module or channel faults early. Configuration and calibration should be periodically verified using Bently Nevada’s 3500 Rack Configuration Software to maintain accurate vibration detection. Modular design allows for hot-swapping, supporting minimal downtime during repairs or upgrades.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626