Description

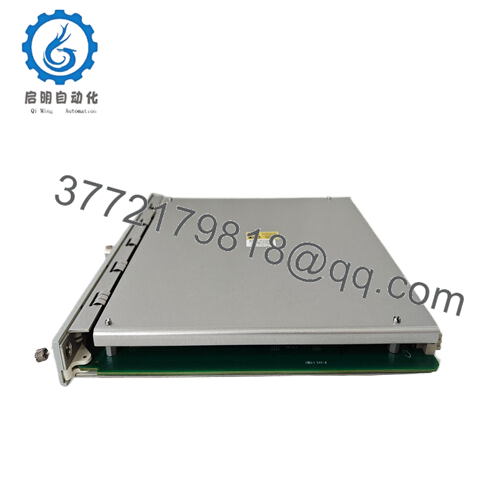

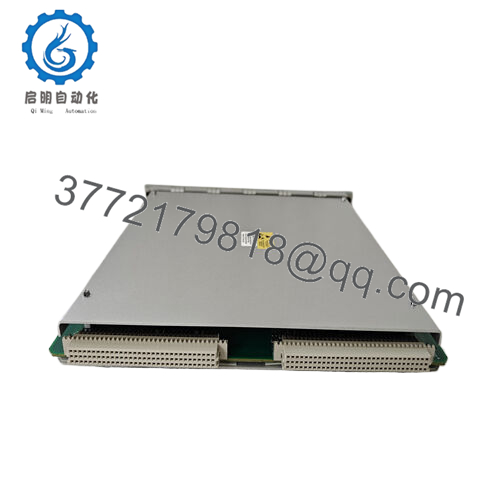

The Bentley Nevada 3500/53 133388-01 vibration monitoring module is the cornerstone of industrial automation architecture. It can easily connect with various control platforms and serve as the “eyes” and “ears” for evaluating the health status of mechanical equipment. This module is compatible with standard backplane systems and can be smoothly integrated into existing industrial environments, minimizing the need for large-scale modifications.

3500/53 133388-01

It is designed to receive input signals from various vibration sensors such as accelerometers and velocity probes. After receiving signals, it will use high-precision algorithms to process these signals and convert the raw data into actionable information. It supports industry-leading communication protocols such as Modbus and Profibus, enabling seamless data sharing in automation networks. This allows operators and engineers to access real-time vibration data from any location in the system, facilitating proactive maintenance and quick decision-making.

3500/53 133388-01

Technical specifications:

Model 3500/53 133388-01

Brand Bently Nevada

Type vibration monitoring module

Input voltage 24 VDC

Operating temperature range -40 ° F to 158 ° F (-40 ° C to 70 ° C)

Installation method: Rack mounted installation

Dimensions (height x width x depth) 9.5 inches x 0.96 inches x 9.52 inches

Weight 0.8 kilograms

Interface/Bus Ethernet RS – 485

Compliance with CE and RoHS

Supports protocols Modbus TCP, Profibus DP, HART

Typical power consumption 10 W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500/53 133388-01

Main features and advantages:

This module is designed specifically for harsh industrial environments, ensuring long-term and stable performance. Its sturdy structure can withstand harsh conditions, including extreme temperature, humidity, and electrical interference, thereby reducing the risk of premature failure. The advanced diagnostic function of this module can not only detect vibration abnormalities, but also accurately locate the root cause of faults, significantly reducing troubleshooting time and engineering costs. By providing accurate and real-time vibration data, it supports predictive maintenance strategies, enabling operators to schedule repairs before minor issues escalate into major failures. This proactive approach minimizes unplanned downtime, extends equipment lifespan, and ultimately reduces overall maintenance costs. In addition, its user-friendly interface and simple integration process make it easy for both beginners and experienced users to get started, making it convenient for rapid deployment in various industrial applications.

3500/53 133388-01

Application areas:

In the aerospace industry, it monitors the vibration of jet engines during testing and operation to ensure safety and optimal performance.

In the mining industry, heavy machinery operates under harsh conditions, and this module closely monitors the vibration levels of crushers, conveyors, and pumps to prevent unexpected failures that may disrupt production and endanger worker safety. In the petrochemical industry, it protects critical equipment such as compressors and turbines, maintains the integrity of the production process, and prevents costly leaks or shutdowns. These applications typically require high reliability and continuous operation, and the Bentley Nevada 3500/53 133388-01 vibration monitoring module, with its outstanding performance and durability, can meet these challenges.

3500/53 133388-01

Related products:

Bentley Nevada 3500/54M: Provides enhanced multi-channel vibration monitoring capabilities, suitable for complex mechanical devices with multiple measurement points.

Bentley Nevada 3500/52M: is a more compact model with basic vibration monitoring capabilities, suitable for small industrial applications with limited space.

Bentley Nevada 3500/50M: Focused on speed monitoring, can be used in conjunction with 3500/53 133388-01 for comprehensive mechanical equipment health assessment, including speed and vibration analysis.

Bentley Nevada 3500/60M: Combining vibration monitoring with other types of measurements such as axial position and temperature provides a more comprehensive view of the condition of mechanical equipment.

Bently Nevada 3500/53-02-01: is a variant of this module with updated firmware and improved signal processing algorithms, providing higher accuracy and reliability in vibration data analysis.

Installation and maintenance:

Before installing the Bentley Nevada3500/53 133388-01 vibration monitoring module, it is necessary to verify the compatibility of the communication interface with the existing control system. Ensure that the power supply voltage matches the requirements of the module and that there is sufficient installation space on the rack. Check the firmware version and update it as necessary to ensure optimal performance and compatibility with other components in the system.

During the continuous maintenance process, regularly check the connectors for signs of wear or loose connections, as these conditions can affect the accuracy of vibration data. Monitor the status indicator lights of the module to detect any potential issues as early as possible. It is also recommended to regularly calibrate the vibration sensors connected to the module to maintain measurement accuracy over the long term.

BENTLY Other product models

Bently 3500/22M 138607/01 Large Card 01AB Version

BENTLY 3500/22M 138607-01

BENTLY 3500/22M 138607-01AE

BENTLY 3500/22M 138607-01 large card

Bently 3500/22M 146031-01 small card

Bently 3500/22M 288055-01 Large Card

Bently 3500/22M cable

Bently Nevada 3500/33 149986-01

BENTLY 3500/22M 138607-01V

BENTLY 3500/33 149986-01

BENTLY 3500/33 149992-01

BENTLY 3500/33 149992-01 Small Card

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/70M 176449-09

Bently 3500/44M 140734-03 Large Card Version 03S

BENTLY 3500/44M 176449-03

BENLTY 3500/60-05-CN

BENLTY 3500/62 163179-03

Bently 3500/64M 176449-05

BENTLY 3500/72M

BENTLY NEVADA 3500/92 136188-02 Small Card

BENTLY 3500/72M 140734-08

BENTLY 3500/91 161204-01

BENTLY 60M500-00-00

BENTLY 3500/65-01-01(145988-02+172103-01)

Bently TK-3E 177313-02-02

Bently 1900/65A-00-01-01-01-01

BENTLY 3500/40M-01-00

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLY 86517-01-01-01-02 159840-01

BENTLY 176449-02

BENTLY 3500/22M 288055-01

BENTLY 288055-01

BENTLY 3500/15-02-02-01

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLEY 3500/65 145988-02 Large Card

BENTLEY 330876-03-50-00-00

Bently 330876-03-90-00-05

Bently 3500/72M 176449-08 large card

Bently 3500/70M 176449-09 large truck

BENTLEY 3500/22M 138607-01 Large Card Old Model

BENTLY 1900/65A-01-01-03-00-01

Bently 149992-01

Bently 3500/45 176449-04 large truck

Bently 3500/42-09-05 128229-01

BENLTY 176449-04

Bently 128229-01 small card

BENLTY 24765-01-01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626