Description

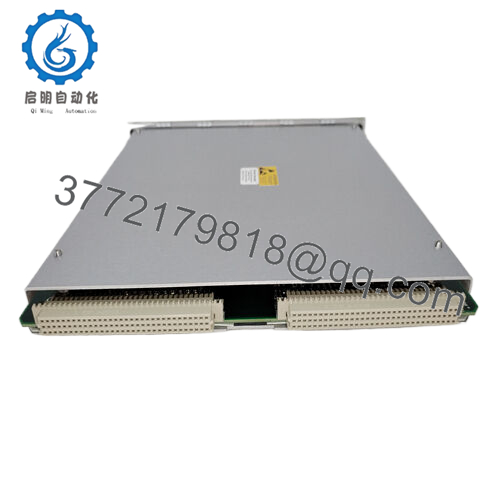

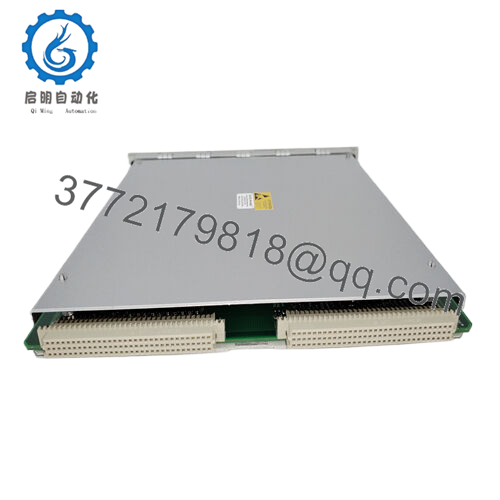

Product Model: Bently Nevada 3500/50

- Product Brand: GE Bently Nevada

- Product Series: 3500 Machinery Protection System

- Product Function: Proximitor Monitor for vibration and position measurements

- Key Features:

- Accepts input from proximity probes

- Provides continuous machine condition monitoring

- Configurable alarm and trip settings

- Integrates with 3500 rack for full machinery protection

Applications and Industry Context

Modern industries rely on high-value rotating machinery such as steam turbines, gas turbines, compressors, and pumps. The health of these machines determines plant productivity, reliability, and safety. Even a minor failure can cause massive production losses and safety risks.

The Bently Nevada 3500/50 Proximitor Monitor plays a central role in preventing such failures. Designed as part of the 3500 Machinery Protection System, the 3500/50 continuously measures shaft vibration and position using proximity probes. By monitoring critical parameters in real time, it provides early warning of developing problems such as imbalance, misalignment, rotor rubs, or bearing wear.

Industries where the 3500/50 is widely applied include:

- Oil & Gas: Protection of compressors, pumps, and turbines in upstream, midstream, and downstream operations.

- Power Generation: Monitoring of steam turbines, gas turbines, and generators for reliable power delivery.

- Petrochemicals & Refining: Continuous monitoring of critical rotating equipment to avoid costly outages.

- Heavy Industry: Steel mills, paper plants, and mining operations where rotating equipment uptime is vital.

With its high reliability and proven track record, the 3500/50 has become the industry standard for machine protection worldwide.

Technical Features and Benefits

The Bently Nevada 3500/50 Proximitor Monitor is built to deliver precision measurements and reliable protection for rotating assets.

Key Features

- Proximitor Input Capability:

The module interfaces directly with Bently Nevada 3300 XL Proximity Probes and other compatible probes to measure shaft vibration and position. - Continuous Machine Monitoring:

Provides 24/7 protection by continuously analyzing signals from probes, ensuring machinery problems are detected before failure. - Alarm and Trip Integration:

Supports configurable alarm setpoints. When vibration or position exceeds safe limits, the monitor initiates alarms and can trigger protective shutdowns. - High Accuracy and Stability:

Advanced signal processing ensures accurate vibration measurements even in electrically noisy industrial environments. - Rack-Based Modular Design:

Installed in the Bently 3500 rack, it integrates seamlessly with other monitoring modules such as temperature, speed, and communication cards. - Programmable Configuration:

Users can configure operating ranges, alarm limits, and channel behavior to match specific machine requirements. - Compliance with API Standards:

Meets API 670 machinery protection standard, ensuring global acceptance in oil & gas and power applications.

Benefits in Operation

- Early Problem Detection: Identifies imbalance, misalignment, rubs, and bearing wear before catastrophic damage.

- Reduced Downtime: Prevents unplanned outages by enabling proactive maintenance.

- Safety Assurance: Provides automatic trip functionality to protect workers and assets.

- Lower Maintenance Costs: Helps schedule maintenance based on machine condition rather than fixed intervals.

- Global Standardization: Backed by GE Bently Nevada’s reputation for reliability and used by leading operators worldwide.

- 3500/50

- 3500/50

System Role and Integration

The 3500/50 is a Proximitor Monitor within the Bently Nevada 3500 rack system. It typically works alongside:

- 3500/42M Vibration Monitors – for radial and axial vibration

- 3500/32M Temperature Monitors – for bearing and casing temperatures

- 3500/22M Transient Data Interface (TDI) – for communication with plant systems

- 3500/40M Proximitor Monitors – for additional vibration/position inputs

A standard setup might include:

- Proximity probes installed near machine shafts.

- Signals sent to the 3500/50 for processing.

- Real-time values compared against user-configured alarm setpoints.

- Alarm or trip relays activated if vibration exceeds safe thresholds.

- Data transferred to DCS, SCADA, or asset management systems via communication cards.

This integration makes the 3500/50 a vital building block in a complete protection and condition monitoring solution.

Technical Specifications

| Specification | Details |

|---|---|

| Model | Bently Nevada 3500/50 |

| Type | Proximitor Monitor |

| Series | 3500 Machinery Protection System |

| Inputs | Proximity probes (shaft vibration/position) |

| Outputs | 4–20 mA, relay outputs, system display |

| Alarms | 2 levels (Alert, Danger) |

| Compliance | API 670 compliant |

| Installation | Rack-based (in 3500 rack) |

| Applications | Turbines, compressors, pumps, critical rotating equipment |

Installation and Maintenance Insights

- Rack Mounting: The 3500/50 slides into the 3500 rack, with keyed connectors to prevent misplacement.

- Probe Setup: Correct placement of proximity probes is crucial for accurate readings. Probe calibration should follow manufacturer recommendations.

- Configuration: Engineers use 3500 Configuration Software to set alarm thresholds, scaling, and channel assignments.

- Maintenance:

- Periodic verification of probe gaps and calibration

- Functional testing of alarm and trip relays

- Regular review of condition data to ensure health of equipment

The modular rack design allows quick replacement of the 3500/50 without disturbing other monitoring channels, minimizing downtime.

Related Bently Nevada Modules

- 3500/42M – Proximitor/Seismic Monitor

- 3500/22M – Transient Data Interface (TDI)

- 3500/32M – 4-Channel Temperature Monitor

- 3500/40M – Proximitor Monitor

- 3500/15 – Power Supply Module

- 3500/25 – Keyphasor Module

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626