Description

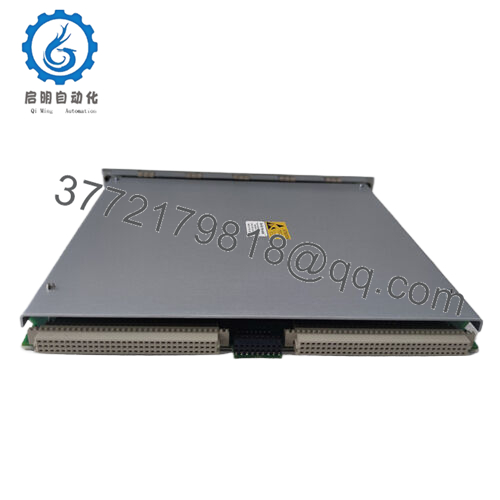

Product Model: Bently Nevada 3500/45 176449-04

- Product Brand: Bently Nevada

- Product Series: 3500 Machinery Protection System

- Product Function: Advanced dynamics monitor for machinery vibration and condition signals

- Key Features:

- Monitors vibration and dynamic signals for rotating machinery

- Integrates into 3500 rack-based system

- API 670 compliant for critical industry use

- Configurable alarms and trip functionality for safety

- 3500/44M 176449-03

- 350045 176449-04

Applications and Industry Context

In heavy industry, oil & gas, and power generation, unplanned shutdowns can mean millions of dollars lost in a single day. At the heart of avoiding these losses is the ability to monitor and protect rotating machinery from failure.

The Bently Nevada 3500/45 176449-04 is designed for precisely this role. As part of the globally recognized 3500 machinery protection system, the 3500/45 captures and processes dynamic vibration and position signals from critical machines like turbines, compressors, and large pumps.

Industries where the 3500/45 is indispensable include:

- Petrochemical refineries: Ensuring compressors and turbines operate within safe vibration levels

- Power generation plants: Protecting turbines and generators from overspeed, misalignment, or bearing failures

- Pipeline operations: Monitoring pumps and motors that run continuously in harsh conditions

- Steel and mining operations: Keeping large rotating kilns, mills, and crushers under surveillance

In each of these contexts, the 3500/45 serves as a guardrail for machine reliability—an ever-vigilant module that continuously checks for conditions that could compromise safety or productivity.

System Role and Integration

The 3500/45 176449-04 is not a standalone instrument. Instead, it is a module that integrates into the Bently Nevada 3500 rack alongside other monitoring and communication units.

Within a rack, the 3500/45 provides channels for processing dynamic vibration signals. It works in tandem with:

- 3500/42M Proximitor/Seismic Monitors for radial and axial vibration inputs

- 3500/32M Temperature Monitors for bearing and casing protection

- 3500/22M Transient Data Interface (TDI) for data exchange with DCS or historian systems

- 3500/15 Power Supply which energizes the entire rack

This modularity means operators can customize a protection system to match the exact needs of each piece of machinery. For instance, a steam turbine may have a rack with several 3500/42M cards for shaft vibration, a 3500/32M for bearing temperature, and a 3500/45 for processing high-fidelity vibration data.

Technical Features and Benefits

The 3500/45 176449-04 offers advanced features designed to meet the demands of critical rotating equipment.

Key Technical Features

- Dynamic Vibration Processing: Handles input from accelerometers, velocity sensors, or proximity probes to measure shaft and casing vibration.

- High Accuracy: Delivers precise readings across a wide dynamic range, ensuring reliable detection of subtle issues before they escalate.

- Configurable Channels: Each channel can be programmed for specific monitoring tasks depending on the machine layout.

- Alarm Functionality: Supports dual-level alarms (Alert and Danger), with relay outputs for triggering machine trips when thresholds are exceeded.

- System Compatibility: Fully integrates with the 3500 rack architecture, communicating seamlessly with other modules.

- API 670 Compliance: Designed in accordance with international standards for machine protection, ensuring trust in demanding industries.

- Modular Hot-Swap Capability: Can be replaced without powering down the rack, minimizing system downtime during maintenance.

Benefits in the Field

- Early Fault Detection: Identifies issues like imbalance, misalignment, resonance, or rubs before they cause catastrophic failures.

- Improved Asset Life: By protecting bearings and rotors, it extends machinery life and reduces maintenance costs.

- Reduced Downtime: Prevents unplanned shutdowns, ensuring maximum production uptime.

- Worker Safety: Automatic trip capability minimizes the risk of accidents caused by mechanical failure.

- Global Acceptance: With wide adoption in oil & gas, petrochemicals, and power, the 3500/45 is trusted across industries.

Technical Specifications

| Specification | Details |

|---|---|

| Model | Bently Nevada 3500/45 176449-04 |

| Type | Dynamics Monitor Module |

| Series | 3500 Machinery Protection System |

| Inputs | Dynamic vibration/position sensors |

| Outputs | 4–20 mA, relay, rack display |

| Alarms | 2 levels (Alert, Danger) |

| Compliance | API 670 |

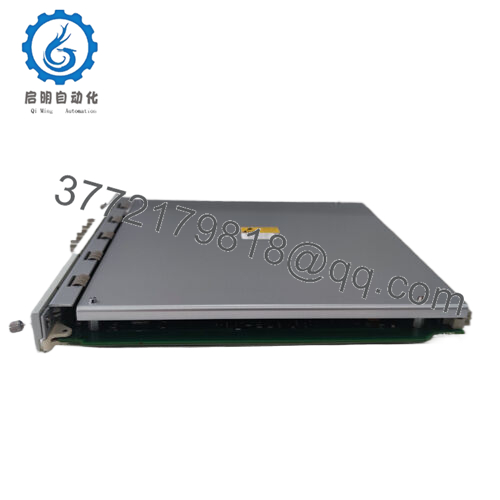

| Installation | Rack-mounted, hot-swappable |

| Applications | Turbines, compressors, pumps, heavy rotating equipment |

| Support | Compatible with 3500/22M TDI for data interface |

Installation and Maintenance Insights

Installing the Bently Nevada 3500/45 requires careful attention to rack configuration. Engineers typically:

- Mount the module into an available rack slot, ensuring proper alignment with the backplane.

- Connect input wiring from vibration sensors, proximity probes, or accelerometers.

- Configure the module channels via 3500 configuration software, assigning measurement parameters and alarm thresholds.

Maintenance best practices include:

- Routine verification of sensor calibration and wiring integrity

- Periodic testing of alarm relay functionality

- Firmware updates and diagnostics during planned outages

- Keeping spares of critical modules like the 3500/45 on site for rapid replacement

Because the 3500/45 is hot-swappable, it can be replaced without powering down the rack, which is especially valuable in continuous-process industries.

Related Bently Nevada Modules

- 3500/42M – Proximitor/Seismic Monitor

- 3500/40M – Proximitor Monitor

- 3500/25 – Keyphasor Module

- 3500/15 – Power Supply Module

- 3500/22M – Transient Data Interface (TDI)

- 3500/32M – 4-Channel Temperature Monitor

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626