Description

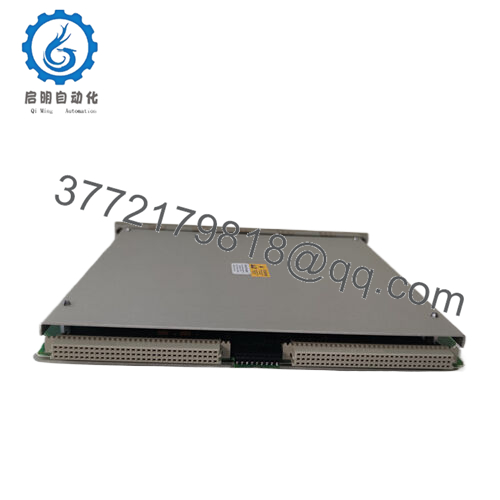

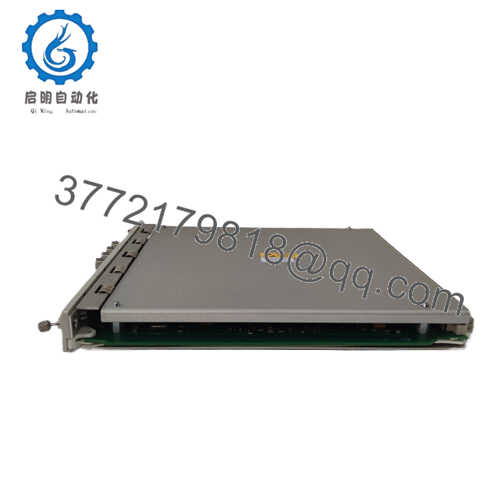

Product Model: Bently Nevada 3500/42M 176449-02

- Product Brand: GE Bently Nevada

- Product Series: 3500 Machinery Protection System

- Product Function: Vibration/Proximitor Monitor Module

- Key Features:

- Monitors radial and axial vibration of rotating machinery

- Provides configurable alarm and trip outputs

- Integrates seamlessly into 3500 rack for machinery protection

- Complies with API 670 standard for industrial applications

Applications and Industry Context

Rotating machinery such as turbines, compressors, and pumps forms the backbone of many industrial operations. Unplanned failures can have dramatic consequences, including costly downtime, safety hazards, and equipment damage. The Bently Nevada 3500/42M 176449-02 is engineered to prevent such failures by providing real-time monitoring of vibration and position signals.

Industries benefiting from this module include:

- Oil & Gas: Continuous monitoring of compressors, pumps, and turbines in upstream, midstream, and refining operations.

- Power Generation: Steam and gas turbines, generators, and associated rotating machinery are monitored to prevent overspeed and excessive vibration.

- Chemical & Petrochemical: Critical rotating equipment is protected against shaft misalignment, imbalance, and bearing wear.

- Mining & Heavy Industry: Crushers, mills, and kilns require continuous vibration monitoring to maintain uptime and safety.

By using the 3500/42M 176449-02, operators gain early detection of potential machinery issues, enabling proactive maintenance strategies that improve reliability and reduce operational risk.

System Role and Integration

The 3500/42M is a core vibration monitoring module in the Bently Nevada 3500 rack system. It works with other modules to form a comprehensive machinery protection system.

Typical integration includes:

- Proximitor inputs: For radial and axial vibration measurements

- 3500/15 Power Supply Module: Provides stable rack power

- 3500/32M Temperature Monitor: Monitors bearing and casing temperatures

- 3500/22M Transient Data Interface (TDI): Connects rack data to DCS or historians

- 3500/50 Proximitor Monitor: For additional vibration/position inputs

The 3500/42M continuously processes vibration data, compares readings against user-defined limits, and activates alarms or trips when necessary. It’s fully compatible with other 3500 modules, enabling seamless integration into a facility-wide condition monitoring strategy.

- 3500/42M 176449 – 02

Technical Features and Benefits

The Bently Nevada 3500/42M 176449-02 is engineered to provide high-precision, reliable vibration monitoring for critical machinery.

Key Features

- Radial and Axial Monitoring: Handles multiple channels of vibration input, capturing the full range of rotor movement.

- High Accuracy and Stability: Ensures precise vibration readings even in electrically noisy or harsh industrial environments.

- Alarm and Trip Outputs: Configurable for two-level alarms (Alert/Danger) to protect assets from catastrophic failure.

- API 670 Compliance: Designed to meet international standards for machinery protection.

- Rack-Based Modular Design: Installed in the 3500 rack, providing flexibility for system expansion or upgrades.

- Hot-Swappable Capability: Allows replacement without powering down the rack, minimizing maintenance downtime.

- Integration with Condition Monitoring Systems: Interfaces with DCS, SCADA, or historian systems via the 3500/22M TDI.

Benefits in Operation

- Early Fault Detection: Detects imbalance, misalignment, resonance, rubs, and bearing wear before failure occurs.

- Reduced Downtime: Allows predictive maintenance planning, avoiding unplanned outages.

- Safety Assurance: Automatic trip functionality protects workers and critical machinery.

- Long Asset Life: By reducing stress on bearings and rotors, the module extends the operating life of critical machines.

- Proven Reliability: Trusted worldwide across multiple industries for decades.

Technical Specifications

| Specification | Details |

|---|---|

| Model | Bently Nevada 3500/42M 176449-02 |

| Type | Vibration/Proximitor Monitor Module |

| Series | 3500 Machinery Protection System |

| Inputs | Radial/axial proximity probes or accelerometers |

| Outputs | Relay outputs, 4–20 mA analog, rack display |

| Alarms | Dual-level (Alert, Danger) |

| Compliance | API 670 |

| Installation | Rack-mounted, hot-swappable |

| Applications | Turbines, compressors, pumps, critical rotating equipment |

| Integration | Compatible with 3500/22M TDI for data transfer |

Installation and Maintenance Insights

Installing the 3500/42M module involves proper alignment within the 3500 rack and connection to input probes. Key points include:

- Rack Mounting: Slide the module into the designated slot in the 3500 rack; keyed connectors prevent incorrect placement.

- Probe Wiring: Connect sensors according to channel assignments; verify signal integrity before commissioning.

- Configuration: Set alarm and trip limits, scaling, and operating parameters using 3500 configuration software.

- Maintenance Best Practices:

- Periodic verification of probe calibration

- Functional testing of alarm relays

- Firmware and diagnostics checks during scheduled maintenance

- Keep spare modules on hand for rapid replacement

Hot-swap capability ensures minimal operational disruption during maintenance.

Related Bently Nevada Modules

- 3500/15 – Power Supply Module

- 3500/32M – Temperature Monitor

- 3500/22M – Transient Data Interface (TDI)

- 3500/45 – Dynamics Monitor Module

- 3500/50 – Proximitor Monitor Module

- 3500/25 – Keyphasor Module

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626