Description

Real-World Use & Application Scenarios

The Bently Nevada 3500-4-1 vibration monitor module is widely used in industries where safeguarding rotating machinery is critical, including power plants, oil and gas facilities, and heavy manufacturing. It addresses real-world challenges in continuous machinery condition monitoring by capturing vibration and shaft position signals, which are essential for early fault detection and prevention of catastrophic machinery failures. This module excels in industrial environments characterized by harsh operating conditions such as extreme temperatures, dust, and electrical noise. The Bently Nevada 3500-4-1 is particularly applicable in control rooms where operators require real-time data to monitor equipment health, reduce unplanned downtime, and extend machinery life. Its dependable signal processing helps engineers implement predictive maintenance and optimize operational efficiency in demanding process control applications.

Product Introduction & Positioning

The Bently Nevada 3500-4-1 is a four-channel proximitor monitor module designed as part of Bently Nevada’s 3500 Series machinery protection systems. It processes signals from proximity transducers to measure radial vibration, thrust position, eccentricity, and differential expansion of rotating equipment. The module features user-programmable alarm thresholds for alert and danger levels, offering flexible and precise machinery protection settings. The 3500-4-1 fits into standard machinery protection racks and communicates critical machine condition data to plant control networks and diagnostic software. Trusted by engineers and plant operators, it is positioned as a core component for machinery condition monitoring to improve safety, reliability, and asset management in industrial automation systems.

Key Technical Features & Functional Benefits

The 3500-4-1 supports four proximity transducer inputs configured for a range of condition monitoring parameters. It offers selectable sensitivity options (3.94 mV/µm or 7.87 mV/µm) suitable for precise vibration displacement measurements. The module incorporates configurable signal filtering between 4 Hz to 4000 Hz or 1 Hz to 600 Hz to optimize signal clarity for various machinery types.

With a power consumption of approximately 7 to 7.7 watts, this monitor operates reliably across a temperature range from -30°C to +65°C and can handle up to 95% relative humidity (non-condensing), showcasing its ruggedness in industrial settings. The front panel includes status LEDs indicating module health, communication status, and bypass mode, facilitating easy diagnostics and operational monitoring. Its analog output impedance and transducer power supply design ensure compatibility with a wide range of industry-standard proximity sensors.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500-4-1 |

| Brand | Bently Nevada |

| Product Type | Four-Channel Proximitor Monitor Module |

| Number of Channels | 4 |

| Supported Measurements | Radial vibration, thrust position, eccentricity, differential expansion |

| Sensitivity Options | 3.94 mV/µm or 7.87 mV/µm (range selectable) |

| Signal Filtering Range | Configurable 4 Hz–4000 Hz or 1 Hz–600 Hz |

| Power Consumption | 7 to 7.7 Watts |

| Operating Temperature | -30°C to +65°C |

| Humidity Range | Up to 95% RH, non-condensing |

| Input Impedance | 10 kΩ standard I/O; 50 kΩ with bussed internal barrier I/O |

| Transducer Power Supply | -24 V DC |

| Output Impedance | ~550 Ω buffered coaxial |

| Dimensions (H × W × D) | ~241.3 mm × 24.4 mm × ~241.8 mm |

| Weight | ~0.91 kg |

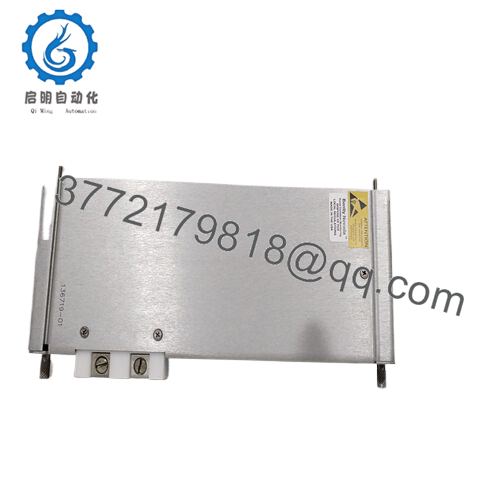

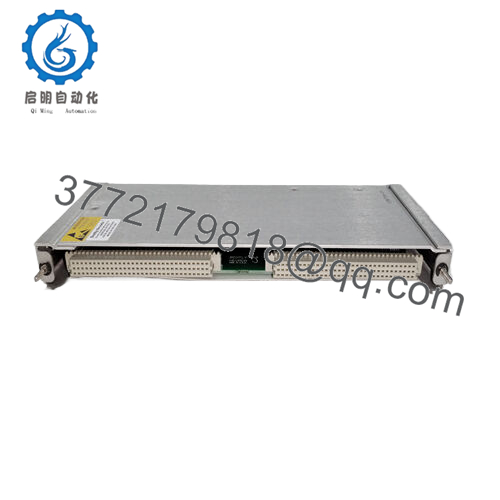

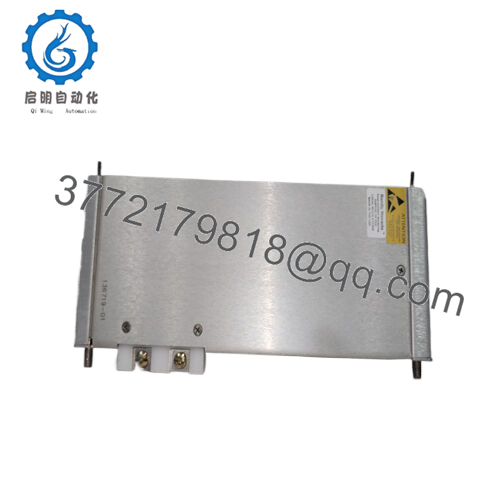

- 3500-4-1

- 3500-4-1

Related Modules or Compatible Units

3500/40M – Extended capability proximitor monitor with additional channel types.

3500/42M – Multi-function proximity and seismic monitor with velocity and acceleration options.

3500/44M – Specialized aeroderivative gas turbine monitor supporting complex vibration analysis.

3500/45 – Position monitor module for differential expansion and thrust monitoring.

3500/60 – Temperature monitor complementing vibration monitoring in machinery protection.

3500/91M – Communication gateway module for integrating with plant-wide control systems.

Installation Notes & Maintenance Best Practices

Install the 3500-4-1 module within designated Bently Nevada 3500 Series racks ensuring firm seating and secure connections. Follow grounding and shielding best practices to minimize electrical noise and interference. Maintain ambient temperature and humidity within specified limits to prolong module life and maintain accuracy.

Routine maintenance includes visual inspection of status LEDs confirming module health, checking connectors for corrosion or looseness, and verifying analog output signals for consistent operation. Use manufacturer software tools for configuration validation and alarm threshold optimizations. Performing periodic calibration per Bently Nevada guidelines ensures measurement accuracy and reliable fault detection.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626