Description

In the mission-critical control rooms of industrial automation, where operators must rapidly interpret a cascade of machinery alerts—from vibration excursions to thrust anomalies—amid varying lighting conditions or remote rack placements, the lack of a versatile, high-resolution interface can transform actionable insights into overlooked oversights. Visualize a turbine monitoring station in a gas processing complex or a compressor bay in a power generation facility: the 3500 rack processes rich diagnostic streams, but relaying them to a central console via legacy serial links often introduces latency or resolution limits, complicating event triage and delaying responses that could prevent API 670 violations or escalate minor rubs into major overhauls. This display disconnect not only strains process control but compounds challenges in high-reliability setups, where a dimmed trend plot or unconfigurable view could mask a speed spike, amplifying downtime risks and regulatory audits that stretch weeks into months.

- 350094M

- 350094M

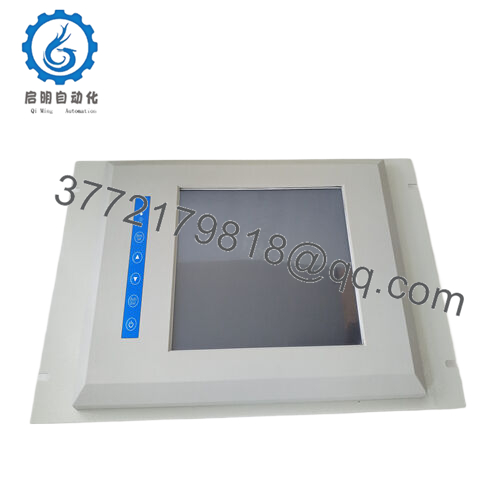

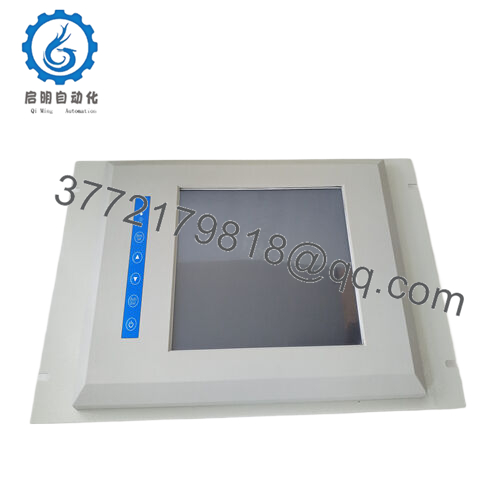

The Bently Nevada 3500/94M addresses this as a VGA Display Module within the 3500 machinery protection series, resolving the visualization void by converting rack telemetry—system events, alarms, channel data, and custom metrics—into touch-enabled, high-resolution VGA outputs that support flexible mounting up to 6 meters standard or 10 km via KVM extenders. It proves vital in distributed architectures, such as multi-rack turbine islands or offshore genset enclosures, where ambient glare or cable constraints demand adaptable interfaces for continuous operator engagement. In rack configurations I’ve supported across expander trains, teams grapple with non-touch panels that necessitate keyboard proxies or fixed views, bloating cognitive loads and validation cycles during night ops. The Bently Nevada 3500/94M streamlines this with up to nine configurable screens via Rack Configuration Software—defaulting to 1X vibration bar graphs or proximity gaps—while its RS232 touch integration and RS422 networking ensure responsive interactions without proprietary overlays. In the visual vanguard of industrial automation, it fortifies the HMI layer with modular clarity, where high-reliability I/O signals manifest as intuitive plots that empower proactive patrols, shifting from reactive reads to resilient reviews that align with SIL 2 workflows.

By bridging rack intelligence to operator vantage with extensible cabling and customizable canvases, the Bently Nevada 3500/94M enables seamless scaling from local consoles to remote KVMs, fostering the interface agility that anticipates alerts before they accumulate. It’s the display dexterity devised for those decision-dense desks in process control, where a pixel’s placement preserves production, delivering the graphical granularity that grounds guardians and guards against glitches.

When integrating the Bently Nevada 3500/94M into a 3500 rack for enhanced HMI harmony, it serves as the visual vanguard in your monitoring matrix, mating via a full-height rear slot with an I/O module to ingest high-speed network data from the rack bus—encompassing module statuses, event lists, and channel scalars—then rendering them on a 10″ or 15″ touch-screen VGA display (VESA-mounted for panel or rack integration) through analog RGB outputs up to 1024×768 resolution. It draws 18-30 VDC from rack rails, with the front RS232 port handling touch controller inputs and the rear providing 24 VDC power out for peripherals, positioning it as the display dispatcher between core rack logic and operator outposts, where FlexLogic echoes feed custom screens like trend overlays or alarm mosaics.

In practice, it syncs via RS422 for distances up to 100 feet (extendable to 4000 feet with external power), polling rack updates at 1-second intervals while software configures views—say, a prioritized alarm list with color-coded severity—diagnostics flagging network faults via status LEDs without rack-wide resets. The touch interface supports gesture-based navigation for zoomable spectra or silence toggles that log back to the TDI, and KVM compatibility enables fiber-extended remote views in control rooms, with galvanic isolation quelling EMI from adjacent HMIs. No auxiliary converters; it emulates standard VGA signals natively, supporting multi-rack router boxes for unified displays across four racks.

This extensibility excels in expansive enclosures, where it pairs upstream with communication gateways like the 3500/92 for Modbus feeds and downstream with keyboards for data entry, enabling redundant displays for SIL 2 paths where one shadows for failover, or hybrids with the 3500/93 for backlit local panels in dusty bays. For retrofits, it upgrades legacy non-touch units without rewiring, its VGA universality easing third-party monitor ties. Far from a static screen, the Bently Nevada 3500/94M animates asset analytics, weaving rack revelations into an interactive process control interface that navigates narratives with native nuance, anticipating the views that validate vigilance.

| Specification | Details |

|---|---|

| Model Number | 3500/94M |

| Brand | Bently Nevada (Baker Hughes) |

| Type | VGA Display Module |

| Input Voltage | 18-30 V DC |

| Operating Temp Range | -20°C to +65°C |

| Mounting Style | Rackmount (Full-Height Rear Slot) |

| Dimensions | 241 x 24 x 242 mm |

| Weight | 0.73 kg |

| Interface/Bus | RS422 / RS232 / VGA Output |

| Compliance | CE, CSA/NRTL/C, API 670 |

| Supported Protocols | Modbus (via rack), Proprietary BN |

| Typical Power Draw | 4.6 W |

Opting for the Bently Nevada 3500/94M instills a spectrum of situational supremacy that sharpens surveillance speed, where touch-enabled trends trace transients in transient temps—envision zooming a vibration envelope during a remote KVM session to confirm a 1X peak, compressing confirmation cycles from minutes to moments and circumventing the console scrambles that stall shifts. Built for the glare-guarded galleries of global guards, it locks in luminous longevity via dimmable backlights and anti-reflective coatings, so overhead halos or harsh fluorescents don’t haze histograms, yielding the interpretive immediacy that informs interlocks and extends event utility without exhaustive exports.

This display also hones human horizons, its nine-screen sprawl and gesture grids streamlining status sweeps to selective scans over scattershot scrolls—crucial in command cores where console clutter cramps cognition and outage optics optimize. Across rack republics, it diminishes display drudgery by dovetailing EIA easels, so panel proliferations proceed without protocol proxies or cabling conundrums, funneling focus to forward-facing features like integrated SOE hooks. Operators obtain operational osmosis from its touch telemetry, where alarm arcs afford affirmative actions intuitively, instilling interfaces that interpret indicators as imperatives, not impositions.

Deeper, the Bently Nevada 3500/94M stewards visual vitality, its RS422 reach rebuffing range restrictions to raise MTBF, while versatile vignettes—events to envelopes—vouch for varied vignettes sans view variants. The vistas vault: veiled variances unveiled to vault values, dossier-distilled dispatches for decree dodges, and the ken to knit narrative nets for narrative nets, all nested in a display that doesn’t dim details, but dazzles them into your automation’s discerning domain.

In gas turbine control consoles, the Bently Nevada 3500/94M renders rack recitals amid fuel fluxes, enduring enclosure eddies to dictate critical system uptime via customizable channel charts—essential for process control environments where view voids could veil valve variances and void verifications. Its KVM kinship conveys clarity under capacity climbs, upholding high reliability in rotors revving remotely.

For refinery compressor HMIs, it’s rack-routed to relay relay recitals through hydrocarbon hazes, prevailing against panel pulses for continuous uptime, with event exports eliciting ESD echoes on escalations. The Bently Nevada 3500/94M bolsters modular integration, broadening bays buoyantly for bed builds without beacon bifurcations.

In power block balance-of-plant panels, the Bently Nevada 3500/94M profiles proximity plots in auxiliary arcs, reinforcing fast data cycles for fault forwards in flow fluxes—harnessed in process control environments hewing to API 670 to hinder house harms and husband heat hauls.

3500/93 – Backlit companion for low-lux local displays in rack-adjacent enclosures.

3500/92 – Modbus gateway sibling for Ethernet-extended HMI in SCADA hybrids.

3500/91 – EGD module counterpart for GE Mark VIe integrations with VGA feeds.

3500/05 – Rack base unit that hosts the 3500/94M in standard 19-inch frames.

1900/30 – Compact legacy alternative for single-rack watches in field skids.

147663-01 – I/O module add-on for the 3500/94M in extended cabling setups.

3500/20 – Frame interface for mounting the 3500/94M in multi-rack expansions.

Before rack-routing the Bently Nevada 3500/94M, map your monitor match—VGA resolutions cap at 1024×768, and RS422 terminators tune for chains to dodge reflections; preset screens via Rack Config in offline mocks to preempt plot lags. Secure rear-slot screws till snug, then test tether through VGA verdicts—steady image on boot pledges protocol pact, flickers flagging fixture fumbles. Display domains differ: deploy distally from dust ducts, with 50mm margins for meniscus-free mounts in mist-mantled manifolds to balk backlight bleeds.

In cadence, quarterly quartz quests at RS232 junctions quell contact corrosion, chiefly in coolant-corroded casings—depower precincts, plumb ports to plane, and plot plunges past 100 kOhm. Semiannually, stage screen simulations with signal sends to scrutinize setpoint stabilities, storing against scales; straying spans signal stage shifts under surveillance. Coordinate annual rack reckonings to refit respites, reenacting events to ratify refresh responses without runtime ruptures, firmware forging post-file frieze. These display doctrines, drawn from dashboard diaries, dynamize the module’s marrow, deflecting the dim drifts that dull diagnostic dawns.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626