Description

Real-World Use & Application Scenarios

In critical machinery protection and condition monitoring applications, clear and reliable visual communication of system status is vital. The BENTLY 350093-01-00-00 System Display module serves this essential function in power plants, oil and gas facilities, and industrial manufacturing sites. It is widely used to provide operators with real-time feedback on machinery health, alarms, and system events crucial for proactive maintenance and preventing catastrophic equipment failures.

Industries deploying Bently Nevada machinery protection systems incorporate the 350093-01-00-00 to visualize key parameters such as vibration, temperature, and running speed monitored by the 3500 Series. Its ability to operate both locally and remotely improves situational awareness, helping plant personnel quickly assess equipment status, alarm conditions, and historical event logs. The module’s intuitive display supports rapid decision-making in environments where uptime and safety are paramount.

- 350093-01-00-00

- 350093-01-00-00

Designed to work in tandem with Bently Nevada’s vast network of sensors and monitoring racks, this display ensures that all critical data streams are presented clearly and efficiently. Its rugged construction endures industrial temperatures and electromagnetic interference, providing consistent performance in demanding environments.

Product Introduction & Positioning

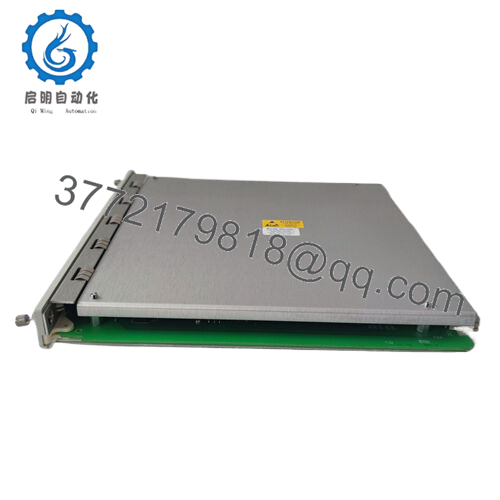

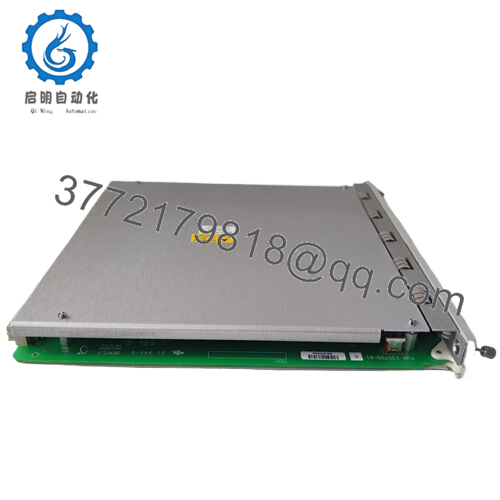

The BENTLY 350093-01-00-00 is a high-performance System Display Interface I/O module designed as part of Bently Nevada’s 3500 Series Machinery Protection System. This module acts as the visual interface connecting operators to comprehensive machine condition data collected across the system’s monitoring racks.

It provides an extensive graphical and textual representation of alarms, system events, channel statuses, and operational parameters, supporting high-speed data acquisition via proprietary or Modbus communication protocols. This display module is flexible in mounting options, including face mount, panel mount, rack mount, and independent mounting configurations, adaptable to various control room layouts and operator preferences.

Engineers and system integrators value the 350093-01-00-00 for its seamless integration capabilities and reliable communication with other 3500 modules, enabling effective machinery monitoring dashboards and control interfaces.

Key Technical Features & Functional Benefits

The BENTLY 350093-01-00-00 features an advanced LCD display with accompanying LED indicators to deliver clear system status at a glance. The module supports high-speed internal network data collection including current values, alarm statuses, event logs, and module health indicators.

It supports multiple mounting configurations with optional backlighting and stainless steel housings for enhanced industrial durability and visibility in low-light conditions. The display interfaces through an RS422 communication link using Bently Nevada’s proprietary protocol and Modbus, ensuring compatibility with a diverse range of control systems.

Power consumption is optimized at approximately 15.5 watts for the display unit combined with the interface module, allowing for efficient energy use within control cabinets. The high-quality construction, environmental resistance, and comprehensive visualization tools aid operators in quickly diagnosing issues and ensuring uninterrupted machinery protection.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | Bently Nevada 350093-01-00-00 |

| Brand | Bently Nevada |

| Product Type | System Display Interface I/O Module |

| Display Type | LCD with status LEDs |

| Communication Interface | RS422, Proprietary and Modbus Protocols |

| Power Consumption | 15.5 Watts (display + interface) |

| Operating Temperature Range | -30°C to +65°C |

| Dimensions | Approximately 41.5 cm x 20.5 cm x 5 cm |

| Weight | 2.1 kg |

| Mounting Options | Face mount, panel mount, rack mount, independent mount |

| Certifications | CE, IEC standards compliant |

Related Modules or Compatible Units

3500/22M Transient Data Interface Module – Necessary for capturing transient vibration data feeding into the system display.

3500/15 Power Supply Module – Provides power regulation for the 3500 series rack components.

3500/32M Relay Module – Facilitates alarm and control relay signal outputs.

3500/42M Monitor Module – Provides analog outputs for variable monitoring integration.

3500/25 Keyphasor Module – Generates tachometer signals critical for vibration phase data.

3500/60 Temperature Monitor Modules – Dedicated for temperature monitoring of machinery components.

Installation Notes & Maintenance Best Practices

The 350093-01-00-00 installation requires ensuring that the display module is mounted securely using the appropriate hardware for the chosen mounting type, whether rack, panel, or face mount. Proper grounding and shielding should be in place to minimize electrical noise affecting communication.

Routine maintenance involves cleaning the display face and housing, verifying LED operational status, and checking communication links. It’s vital to schedule software and firmware updates regularly to maintain compatibility and functionality with other 3500 system modules. Operational logs and alarms visible on the display should be routinely reviewed for early detection of potential system issues.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626