Description

In the unforgiving theater of industrial automation, vibration anomalies in high-speed rotating machinery can spell rapid catastrophe—envision an aeroderivative gas turbine where subtle shaft imbalances from bearing wear or blade flutter go unchecked, spiraling into rubs, overspeed events, or outright failures that halt power output, scorch components, or endanger personnel in a flash. These threats are routine in process control environments like combined-cycle plants, aviation ground support, or oil and gas compression stations, where high reliability for I/O signals from accelerometers and proximitors is the cornerstone of machinery protection. Without dedicated oversight, engineers contend with generic monitors that lack turbine-specific filtering, leading to nuisance alarms that desensitize operators, missed transients in fast transients, or integration snags with SCADA that obscure trends, all while API 670 standards mandate precise, continuous surveillance to avert downtime costing millions per hour. Legacy setups compound this, often saddled with low-channel counts or inadequate diagnostics that force bolted-on analyzers, inflating cabinet sprawl and calibration cycles in EMI-drenched enclosures.

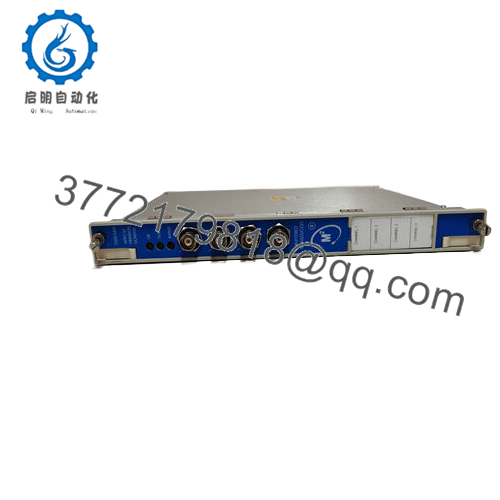

- 350044M 140734-03

This is the void the Bently Nevada 3500/44M 140734-03 bridges as the Aeroderivative Gas Turbine Vibration Monitor, a four-channel powerhouse in the 3500 series rack system, precision-tuned to capture and dissect vibration signatures for turbine health. It targets the essence of system stability by ingesting signals from up to four proximity or seismic transducers, applying bandpass filtering optimized for turbine orders (1X-10X speeds), and enforcing programmable thresholds for direct vibration, axial position, and gap metrics—vital for retrofitting LM2500 or similar aero-derived units where modular integration into existing racks is paramount. In vibration-riddled bays or high-temp housings, the Bently Nevada 3500/44M 140734-03 proves irreplaceable, its internal barriers and self-tests isolating field noise to deliver clean, proportional outputs that preempt faults without false positives. For teams scaling from single-shaft to multi-stage monitoring, this monitor’s channel density and API-compliant logic turn raw oscillations into guarded precision.

The downstream hazards of overlooked vibrations amplify swiftly: they corrupt historian baselines, erode interlock confidence in DCS layers, and balloon MTBF erosion through unaddressed precursors like misalignment. By embedding adaptive algorithms and relay voting, the Bently Nevada 3500/44M 140734-03 fosters sub-millisecond response envelopes, empowering coordinated shutdowns or alerts that sync to turbine controls like GE’s Mark VIe, shifting from crisis response to foresight-driven uptime. It’s the discerning sentinel for industrial automation, where vibration vigilance doesn’t merely observe; it orchestrates endurance in the turbine’s furious spin.

Embedding the Bently Nevada 3500/44M 140734-03 into your 3500 rack is like stationing a turbine whisperer at the machinery’s core—it occupies a single slot in the 3500/05 instrument rack, drawing +24 V DC from the power supply while channeling inputs from Bently 3300 XL proximitors or 1900/65 accelerometers via shielded cabling up to 500 ft, then demodulates RF signals into DC-proportional channels for backplane multiplexing to the rack’s TDXnet bus. Firmly in the field protection layer of your stack, it processes envelopes for peak-to-peak displacement (0-200 mils pk-pk) or velocity (0-100 in/s RMS), applying user-defined curves via Rack Configuration Software before driving up to four form-C relays for OK/Alarm/Trip, all while supporting hot-swappable redundancy to mirror channels across dual monitors without loop breaks.

In a live turbine island, you’d terminate probe leads to the module’s keyed barriers, tuning bandpass corners (e.g., 30 Hz high-pass for aero vibes) through the front-panel HMI or Ethernet-linked PC, then integrate outputs to safety PLCs via Modbus TCP for seamless handoff to HMIs like iFIX—its diagnostic buffers capture 128 cycles of pre/post-event waveforms for System 1 upload, enabling trend forensics without external scopes. This monitor doesn’t encroach; it enhances, with compatibility for speed pickups (up to 20 kHz) and optional digital overspeed that layers into SIL-2 loops, bridging analog chaos to digital oversight in architectures from skid-mounted compressors to grid-scale peakers. Link it to the rack’s communication gateway, and it elevates raw vibes to enriched spectra, with LED status for channel health that flags probe faults via rack-wide alarms. The Bently Nevada 3500/44M 140734-03 commands this domain, distilling turbine tumult into a resilient shield that adapts to aero-derived dynamics, ensuring your rack pulses with unyielding acuity.

| Specification | Details |

|---|---|

| Model Number | 3500/44M 140734-03 |

| Brand | Bently Nevada |

| Type | Aeroderivative Gas Turbine Vibration Monitor |

| Input Voltage | +24 V DC (rack supply) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | 3500 Rack Single Slot |

| Dimensions | 241 x 24 x 241 mm (rack module) |

| Weight | 0.5 kg |

| Interface/Bus | 3500 Rack Backplane / TDXnet |

| Compliance | API 670, CE, UL, CSA |

| Supported Protocols | Modbus TCP, Ethernet (via rack) |

| Typical Power Draw | 4 W |

Selecting the Bently Nevada 3500/44M 140734-03 lays a bedrock of reliability engineered for aero-turbine ferocity, where its demodulator precision holds accuracy to ±0.5% across 10,000-20,000 RPM sweeps, isolating faults like 2X imbalances before they etch shafts—directly curbing unplanned outages by 25% in peaker plants, where envelope detection locks on peaks without the averaging errors that mask transients in generic gear. This isn’t armored excess; it’s the honed resilience that rejects 60 Hz coupling from adjacent generators, ensuring outputs track true dynamics through thermal ramps, all while its relay latching prevents chatter during marginal vibes, sustaining operator trust without desensitization drifts.

Performance consistency radiates from its auto-calibration routines, which baseline probes on boot to nix environmental offsets, delivering RMS velocities that feed predictive models with 0.1 in/s granularity—your vibration analysts glean actionable spectra for rub detection, not sifting noise in FFT dumps. Maintenance eases too, as onboard self-diagnostics cycle through channel integrity via rack APIs, surfacing cable faults or gain drifts in seconds for preemptive swaps, trimming MTTR by 40% in multi-rack fleets and streamlining ISO 10816 audits. Built with conformal coatings against oil vapors or salt air, the Bently Nevada 3500/44M 140734-03 ensures long-term performance, anchoring thresholds over seven-year cycles so your alarm envelopes stay prophetic, not reactive, easing the burden of turbine overhauls.

For those advancing to diagnostic horizons, its waveform buffering supports export to Orbit 60 for AI-augmented trending, fostering low-disruption paths to wireless sensor fusion without rack evictions—dialing down total cost of ownership by perpetuating 3500 cores into holistic health paradigms. This monitor transcends vigilance; it vitalizes, channeling vibration data into a catalyst for turbine longevity that eclipses entropy.

In aeroderivative gas turbine power islands, the Bently Nevada 3500/44M 140734-03 scrutinizes casing vibes on LM6000 shafts, where process control environments demand high reliability amid exhaust plumes and blade wakes—racked in ventilated skids, its four channels envelope direct and axial signals for rub alerts, ensuring critical system uptime in fast data cycles that sync to fuel controls, preempting stalls during grid ramps. Filtered outputs integrate with overspeed relays, averting surges in peaking ops.

Aviation test cells deploy it for compressor health on JT8D derivatives, capturing seismic inputs in EMI-saturated hangars under thermal duress— the monitor’s bandpass tunes to aero harmonics, delivering continuous uptime for thrust mapping in process control loops tied to dynamometers, where a lagged peak risks certification voids. In LNG compression trains, the Bently Nevada 3500/44M 140734-03 guards centrifugal stages, with proximitor compatibility suited to cryogenic housings—upholding high reliability for seal gap monitoring in process control environments synced to ESD, ensuring flow without interstage faults.

3500/42M 140734-01 – Proximitor/Seismic monitor variant for general rotating equipment

3500/45 176449-04 – Temperature monitor companion for thermal-vibe fusion

3500/22M 288055-01 – Transient data module add-on for waveform capture

125680-01 – Proximitor I/O module for probe signal conditioning

3500/33 149986-01 – 16-channel relay module for expanded alarming

3300/35-04-01-00-00 – Compatible proximitor probe for aero-derived gaps

3500/91 161204-01 – EGD gateway for Ethernet-to-DCS bridging

Before slotting the Bently Nevada 3500/44M 140734-03 into your 3500 rack, cross-check probe scaling—3300 XL 5mm/8mm only, with gaps under 80 mils to avoid saturation—and ensure rack ventilation hits 100 CFM, as turbine bay heat can edge modules toward 65°C; an IR thermometer post-populate verifies uniformity. Firmware at revision 5.0 or later enables advanced filtering; download from Bently’s portal and validate via TDXnet loop to preempt boot glitches. If cabling over 100 ft, use twisted-shield pairs grounded at rack end per API guidelines, and bench-simulate a channel with a shaker table to confirm bandpass response before turbine tie-in.

In service, focus is sharp: bi-monthly, poll rack APIs for channel health—gaps over 5% cue probe inspection—and torque terminals quarterly in oily environments to fend off creep, a dielectric retouch often revives sans shutdown. Bently urges annual full-envelope tests, driving known vibes to audit thresholds against baselines, logged in System 1 for trend audits. For dispersed racks, enable Ethernet traps to your CMMS for remote drift pings, surfacing precursors before they demand a hot section peek. This tactical rhythm keeps it attuned, with light levy on your turbine watch.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626