Description

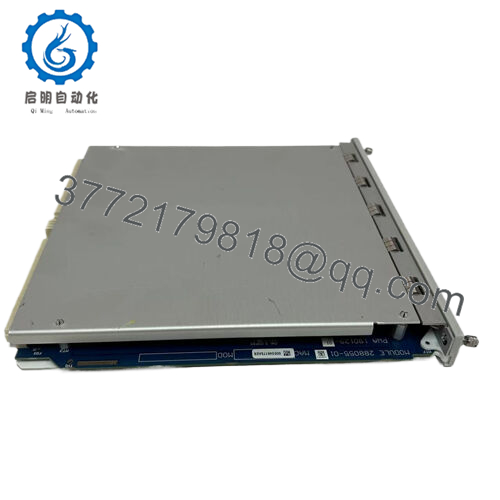

The BENTLY 350022 288055-01 serves as a crucial link between various sensors and the overall control system. It interfaces seamlessly with Bently’s 3500 Monitoring System, a widely recognized platform in the industrial monitoring landscape. Positioned within the system’s rack-mounted architecture, this module receives raw analog signals from sensors such as accelerometers, proximity probes, and thermocouples.

350022 288055-01

Equipped with advanced analog-to-digital conversion technology, it transforms these raw signals into clean, digital data suitable for analysis by higher-level control platforms, including PLCs and DCS systems. The module supports standard industrial communication protocols like Modbus and Profibus, facilitating smooth integration with existing automation setups. Its built-in diagnostic features continuously monitor signal integrity and module health, alerting operators to any potential issues through intuitive status indicators. This proactive approach to diagnostics ensures that any problems are identified and resolved promptly, minimizing the risk of system-wide disruptions. In the automation stack, the BENTLY 350022 288055-01 acts as a reliable data gateway, enhancing the overall efficiency and reliability of industrial monitoring and control systems.

350022 288055-01

Technical specifications:

Model NumberBENTLY 350022 288055-01

BrandBently Nevada (A Baker Hughes Business)

TypeMonitoring and Signal Conditioning Module

Input Voltage24 VDC ±10%

Operating Temp Range-40°C to +70°C (-40°F to +158°F)

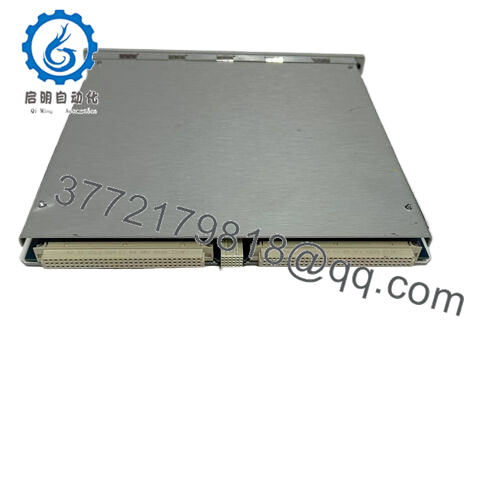

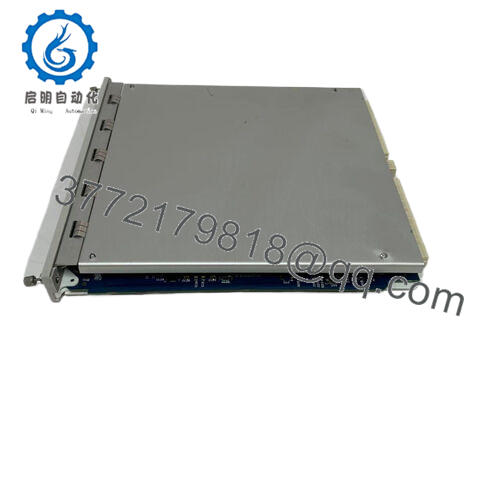

Mounting StyleRack-mountable (fits into Bently 3500 rack system)

Dimensions177.8 mm (W) x 254 mm (D) x 44.45 mm (H) (7″ x 10″ x 1.75″)

WeightApproximately 1.5 kg (3.3 lbs)

Interface/BusSerial (RS-485), Ethernet for data communication

ComplianceCE, RoHS, IEC 61000-4-2 (Electrostatic Discharge Immunity)

Supported ProtocolsModbus TCP, Profibus DP, Bently Proprietary Protocols

Typical Power Draw18 W (idle), 22 W (full load)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

350022 288055-01

Main features and advantages:

350022 288055-01

Application areas:

350022 288055-01

Related products:

- BENTLY 350022 288055-02 – An upgraded version with enhanced data processing speed for more demanding applications.

- BENTLY 350020 288053-01 – A similar module with a reduced channel count, suitable for smaller-scale monitoring systems.

- BENTLY 350025 288058-01 – Offers additional input channels and advanced diagnostic capabilities for complex industrial setups.

- BENTLY 350019 288052-01 – A cost-effective alternative with basic monitoring functions, ideal for less critical applications.

- BENTLY 350023 288056-01 – Designed for high-speed data acquisition, perfect for monitoring fast-rotating machinery.

- BENTLY 350024 288057-01 – Features redundant communication interfaces for enhanced system reliability in mission-critical operations.

350022 288055-01

Installation and maintenance:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626