Description

Product Introduction & Positioning

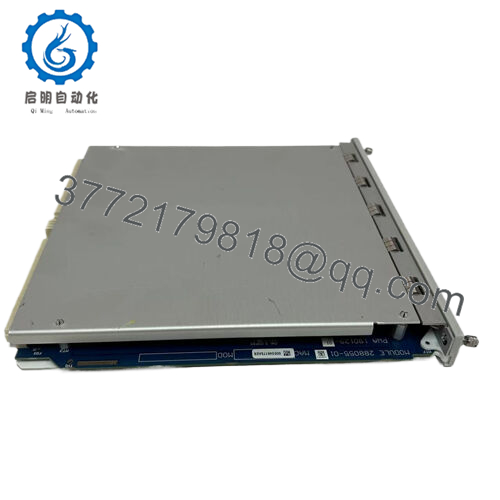

The BENTLY 3500/22 288055-01 is a Transient Data Interface (TDI) Module designed to bridge the Bently Nevada 3500 Series hardware monitoring system with diagnostic software like System 1™. It combines the functionalities of a rack interface module and a high-capacity communication processor, handling both steady-state and dynamic waveform data collection. This module occupies a full-height slot in the 3500 rack and features multiple communication interfaces including autosensing 10Base-T/100Base-TX Ethernet and 100Base-FX fiber optic, supporting long-distance, low-latency data transmission up to 2000 meters. Engineers value the 288055-01 for its role in capturing high-resolution transient signals and integrating them into centralized diagnostic workflows, enabling sophisticated analysis and trending of machinery behavior over time.

- 350022 288055-01

Key Technical Features & Functional Benefits

The 288055-01 consumes approximately 10.5 watts and is designed for industrial operating temperatures from -30°C to +65°C with storage tolerances from -40°C to +85°C. Its front panel includes a USB-B port for local communication, along with multiple LEDs indicating power, communication status, rack trip mode, and configuration validity. The module offers a user-selectable relay output to signal system health, operable in normally open or normally closed configurations.

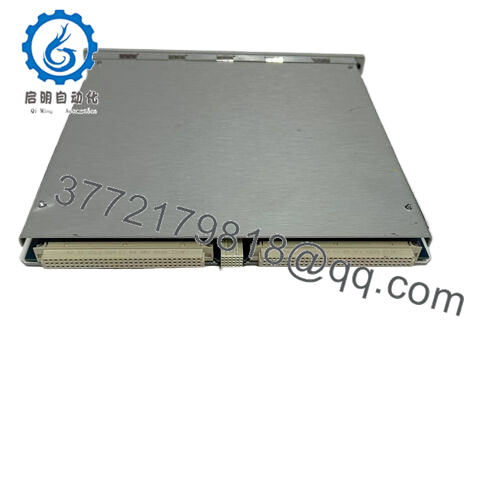

Supporting both Ethernet and fiber optic connections, the module’s interface autosenses communication speed and adapts accordingly, ensuring compatibility with diverse plant network architectures. The fiber optic connection supports multimode cables up to 2000 meters to maintain signal integrity over long distances. With a weight of 0.91 kg and dimensions of 241.3 mm by 24.4 mm by 241.8 mm, it fits seamlessly into standard Bently Nevada 3500 racks without requiring additional space or modifications. The module’s battery-backed memory stores diagnostics and waveform data with exceptional retention times — 38 years powered and 12 years unpowered at 50°C — safeguarding critical transient data for long-term asset condition assessment.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500/22 288055-01 |

| Brand | Bently Nevada / GE |

| Product Type | Standard Transient Data Interface Module |

| Power Consumption | Approx. 10.5 Watts |

| Data Communication | USB-B port, 10Base-T/100Base-TX Ethernet, 100Base-FX Fiber Optic |

| Max Cable Length | 100 meters (Ethernet), 2000 meters (Fiber Optic) |

| Operating Temperature | -30°C to +65°C (-22°F to 149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to 185°F) |

| Operating Humidity | 95%, non-condensing |

| Weight | 0.91 kg (2.0 lbs) |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 241.8 mm (9.50 in x 0.96 in x 9.52 in) |

| Front Panel Indicators | OK, TX/RX, Trip Multiply, Config OK LEDs |

| Relay Output | User selectable open/closed contact, Normally energized |

| Battery Life (Memory Backup) | 38 years powered / 12 years unpowered at 50°C |

| Hazardous Area Certifications | Class 1, Division 2, Groups A-D, T4 options available |

Related Modules or Compatible Units

146031-01 3500/22 Ethernet I/O Module – Provides Ethernet connectivity complementary to the 288055-01.

146031-02 3500 Series 100Base-FX Fiber Optic I/O Module – Supports fiber optic communication with the 3500/22.

3500/15 AC Power Supply Module – Supplies power to the 3500 rack including this interface module.

3500-20 Rack Interface Module – Primary rack communication controller designed to coordinate modules with the 3500/22.

System 1™ Software – Advanced diagnostic platform for transient data collected by the 3500/22.

3500/22 Transient Data Interface (TDI) Upgrade Kit – Enables dynamic data capture on the 3500/22 platform.

3500/04 Internal Barriers – Provide intrinsic safety for signal lines connected to the 3500/22 module.

3500/21M Standard Transient Data Interface Module – Previous generation transient data module compatible with the 3500 system.

Installation Notes & Maintenance Best Practices

Installation of the 288055-01 module requires placement in a full-height front slot of the 3500 Series rack. Ensure communication cables meet length, shielding, and connector specifications — with fiber optic cable connectors specifically requiring MT-RJ Female ends. Grounding and environmental contaminant protection are essential to preserve signal integrity and module longevity.

Routine maintenance includes monitoring front panel LEDs, verifying communication pathways, and backing up module data memory regularly. Firmware and configuration updates should be managed via the USB or Ethernet interface to maintain system compatibility. Battery health should be monitored according to datasheet guidelines to prevent data loss during power outages. All service and repair operations must adhere to Bently Nevada’s recommended procedures to ensure certified performance and safety.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626