Description

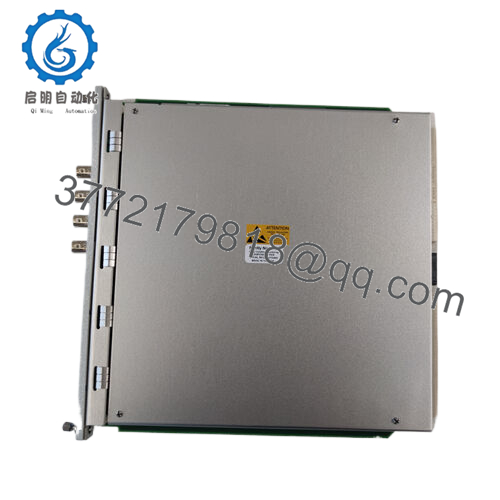

BENTLY 3500/70M is a single slot four channel pressure monitoring module, which is the core component of the trusted 3500 series modular platform for critical mechanical protection. Its core function is to measure, regulate, and transmit pressure signals from sensors, providing actionable insights for alarm activation, process optimization, and predictive maintenance.

3500/70M

Each channel receives analog input from high-temperature pressure sensors (such as strain gauges, piezoelectric sensors) and processes it through configurable algorithms. Engineers can adjust signal conditioning parameters such as low-pass filtering (0.1-1000 Hz), peak detection, and rate of change limitation to separate meaningful pressure trends from noise. This module supports static pressure (such as pipeline baseline pressure) and dynamic pressure (such as pump pulsation), and the output format can be directly integrated into the human-machine interface (HMI), monitoring and data acquisition (SCADA) system, or 3500 series backplane.

For system integrators, the 3500/70M is seamlessly compatible with other 3500 series modules, simplifying rack setup and reducing wiring complexity. It complies with API 670 and ISO 13849 standards, ensuring reliability in safety critical applications, while firmware updates through BENTLY’s AMS Suite software ensure future adaptability of its functionality.

3500/70M

Main features and advantages:

High temperature performance: Supports sensors up to 482 ° C (900 ° F), suitable for extreme environments such as gas turbine combustion chambers or refinery reactors.

Configurable signal conditioning: Each channel allows for independent setting of filtering, alarm dead zones, and pressure change rate limits, which can be fine tuned for various applications ranging from slow pressure changes in storage tanks to high-frequency pulsation analysis of reciprocating compressors.

Redundant architecture: Dual isolated power supplies and channel level diagnostics ensure continuous operation even in the event of a channel failure, which is crucial for industries such as pharmaceuticals or water treatment that require 24/7 operation.

Real time health monitoring: The built-in self-test function can verify sensor connections, cable integrity, and module temperature, reducing the average time to fault identification (MTID) by up to 50%.

Scalable data integration: Provides 4-20 mA analog output for local control systems and digital data through the 3500 series backplane, which can be integrated with AI driven analysis tools to predict pressure related faults.

3500/70M

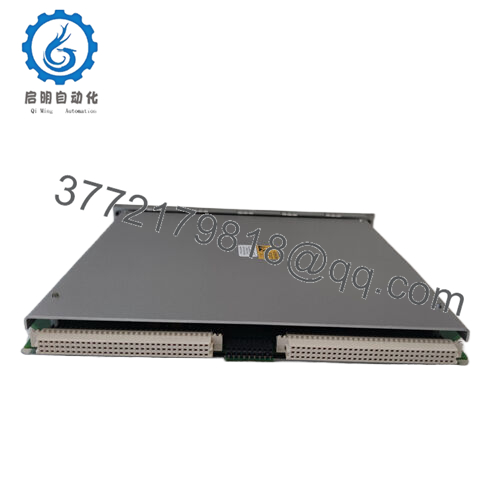

Technical specifications:

Model 3500/70M

Brand BENTLY

Type Four Channel Pressure Monitoring Module

System compatibility 3500 series mechanical protection system

Input range 0-100 mV (from sensor), configurable pressure range up to 10000 psi

Signal conditioning low-pass filtering (0.1-1000 Hz), peak holding, rate of change detection

Accuracy ± 0.1% of full scale

Power supply 24 VDC (10-30 VDC range), dual isolated input

Working temperature -40 ° C to 85 ° C

Storage temperature -55 ° C to 125 ° C

Vibration immunity 5 g (5-2000 Hz, IEC 60068-2-6)

Certified API 670, CE, UL, CSA, IEC 61508 (SIL 2 compatible)

Dimensions 48.3 mm (height) x 177.8 mm (width) x 254 mm (depth)

Weight 0.9 kg

Output 4-20 mA analog output per channel, transmit digital status messages through the backplane

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500/70M

Application areas:

Accurate pressure control is crucial for the safe separation of hydrocarbons in the distillation tower of a petrochemical plant. The 3500/70M can be used in conjunction with a high-temperature pressure sensor to detect subtle pressure fluctuations caused by valve wear, corrosion, or blockage. By issuing abnormal pressure trend alerts to operators (such as sudden increases or continuous decreases in pressure), it can adjust in a timely manner to prevent catastrophic failures such as container rupture or toxic leaks.

In power plants, this module monitors the steam pressure of the turbine to ensure efficient energy conversion, while also marking any abnormal conditions that may cause blade erosion or boiler instability. For hydraulic systems in heavy machinery or aerospace manufacturing, the 3500/70Mcan track rapid pressure changes during operation to prevent damage caused by hydraulic shock or component fatigue.

The robust and durable design of this module makes it indispensable in harsh environments, often exposed to extreme temperatures, humidity, and vibrations in offshore platforms or steel plants. By integrating with the BENTLY 3500 series mechanical protection system, it centralizes pressure data and achieves cross correlation with parameters such as temperature or vibration for comprehensive mechanical diagnosis.

3500/70M

Related products:

BENTLY 3500/22M – Keyphase and speed measurement mechanical protection module, suitable for associating pressure shock with mechanical speed (e.g. identifying cavitation phenomena in pumps).

BENTLY 3500/32- Four channel displacement module, can be used in conjunction with 3500/70M to monitor mechanical deformation caused by extreme pressure in containers or heat exchangers.

BENTLY 3500/92- Communication gateway module that supports integrating pressure data into cloud platforms (such as AWS IoT) for remote monitoring and predictive analysis.

BENTLY 3500/05- Rack power supply ensures stable power supply to 3500 series racks, which is crucial for maintaining measurement accuracy during voltage fluctuations.

BENTLY 3500/60M – Temperature monitoring module, can be used in conjunction with pressure data to analyze thermal expansion effects or overheating risks in high-pressure systems.

BENTLY 3500/15- Relay module that performs safety actions (such as emergency stop, valve actuation) based on pressure alarms at 3500/70M.

3500/70M

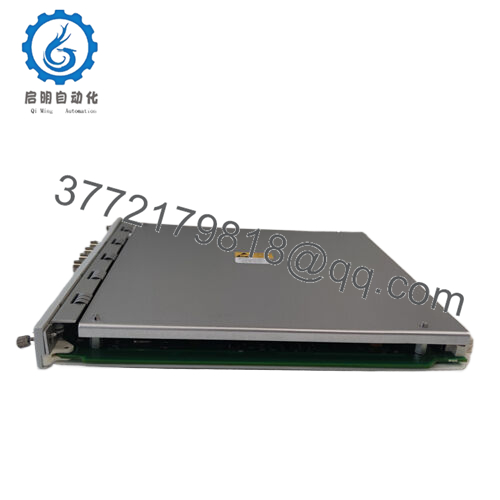

Installation and maintenance:

Before installation:

Use shielded twisted pair cables to connect sensors and maintain a minimum distance of 30 cm from high-voltage lines to reduce electromagnetic interference (EMI)/radio frequency interference (RFI).

Before installation, calibrate the pressure sensor with a NIST traceable reference pressure gauge to ensure accuracy within ± 0.05% of full scale.

Configure alarm setpoints during debugging, following the original equipment manufacturer (OEM) guidelines for mechanical equipment (e.g. 110% of normal operating pressure as the shutdown trigger point).

maintain:

Use a portable pressure calibrator for loop checks every quarter to verify the accuracy of the entire signal chain (from sensors to module outputs).

Check the sensor installation flange annually for leaks or corrosion, especially in saltwater or acidic environments.

Update firmware annually through BENTLY AMS Suite to access new features such as advanced impact detection or enhanced diagnostic programs.

Clean module vents and terminal blocks every six months in dusty or humid environments to prevent the accumulation of conductive residues.

BENTLY Other product models

BENTLY 84661-50

BENLTY 3500/92-04-01-01

BENLTY 3500/70-01-00(176449-09+140471-01)

BENLTY 176449-03

BENTLY 330881-28-08-120-00-02

BENTLY 330881-28-08-060-00-02

BENTLY 990-04-ХХ-01-05 165335-01

BENLTY 3500/91M 190782-01

BENLTY 3500/61 163179-02

Bently Nevada 3500/50-04-002

BENLTY 3500/25M-02-02

BENLTY 3500/42M-04

BENLTY 3500/33-01-01

BENLTY 3500/92-04-01

BENLTY 3500/45 176449-04

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 3500/22-01-01-R0

BENLTY 3500/92-04-01-R0

BENLTY 330851-02-000-060-10-00-00

BENLTY 3500/65 172103-01 small card

BENLTY 3500/22M 288055-01 Large Card

BENLTY 3500/40M 176449-01 Large Card

BENLTY 3500/65 145988-02 Large Card

Bently 3500/54 133396-01

Bently 3500/54 286566-01

BENLTY 3500/22-01-01-00

BENLTY 3500/22-01-01-00

BENLTY 3500/92-04-01-R0

BENLTY 3500/15-05-05-R0 front and rear card set

BENLTY 3500/62 136483-01

BENLTY 330103-00-03-05-02-05

BENLTY 3500/22 288055-01

BENLTY 3500/22 288055-01 large truck

BENTLY 3500/62 136483-01 small card

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626