Description

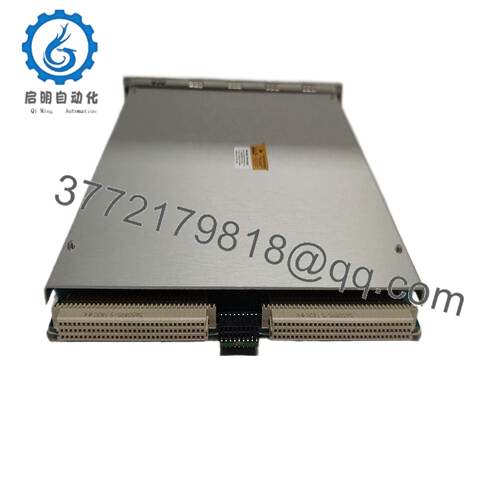

BENTLY 3500/54-03-00 is a dual channel overspeed detection module that is part of the industry-leading 3500 series, a trusted modular mechanical protection platform. Its core function is to measure the speed with sub millisecond accuracy and distinguish between normal operating changes and dangerous overspeed conditions through advanced signal processing technology.

3500/54-03-00

As a key component of the 3500 series architecture, this module receives raw speed signals from sensors, processes the signals through configurable algorithms, and outputs relay signals to trigger alarms (such as pre trip warnings) or emergency shutdowns. Its dual channel design provides redundant functionality, ensuring the avoidance of single point failures in high availability systems. For system integrators, the 3500/54-03-00 simplifies the deployment process: it can be plugged into a 3500 series rack and shares a common backplane with other modules (such as vibration and temperature modules) for data communication and power supply.

The difference of this module lies in its flexibility: it supports multiple sensor types (proximity sensors, magnetic pickups) and adapts to a wide range of speeds (0-50000 RPM), suitable for various devices from small pumps to large turbine generators. It complies with API 670 and IEC 61508 standards, ensuring strict safety requirements in hazardous environments, while firmware updates are made through BENTLY’s AMS Suite software to ensure its future adaptability.

3500/54-03-00

Main features and advantages:

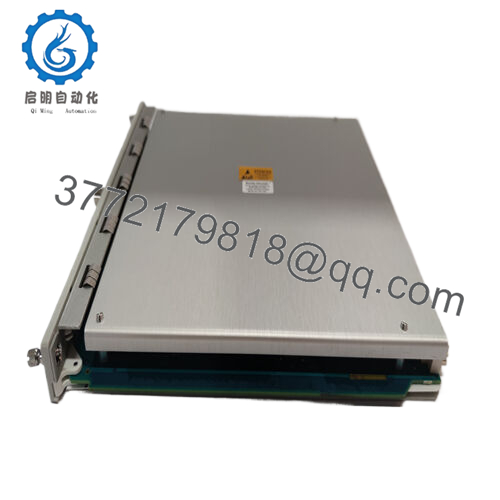

High precision speed measurement: By utilizing 24 bit ADC and digital filtering technology, a speed accuracy of ± 0.1% can be achieved even in strong noise environments. This allows for early detection of subtle speed deviations (such as those caused by bearing wear or misalignment), preventing them from escalating into faults.

Redundant design: Dual independent channels are equipped with independent power and signal paths to ensure continuous operation even in the event of a channel failure. Each channel can be configured with unique alarm setpoints to achieve layered protection (e.g. channel 1 triggers an alarm; channel 2 starts and stops).

Durable hardware: capable of operating within a temperature range of -40 ° C to 85 ° C and withstanding 5 g of vibration, suitable for harsh industrial environments. The compact 1U external dimensions are suitable for standard 3500 series racks, optimizing space utilization in crowded control rooms.

Configurable logic: Engineers can program parameters such as acceleration trip limits, speed band monitoring, and zero speed verification. For example, in wind turbine applications, the module can be set to trigger a shutdown if the speed increases by 10% within 2 seconds (indicating a potential governor failure).

Seamless integration: Communicate through the 3500 series backplane to share data with HMI, SCADA systems, or cloud analysis platforms, enabling remote monitoring and predictive maintenance workflows.

3500/54-03-00

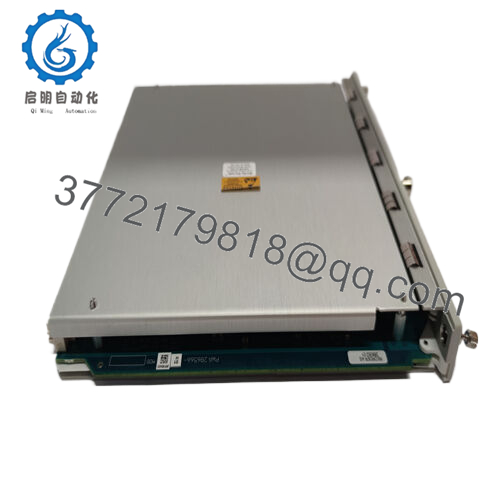

Technical specifications:

Model 3500/54-03-00

Brand BENTLY

Type: Dual channel overspeed detection module

System compatibility 3500 series mechanical protection system

Sensor input 2 channels (proximity sensor, magnetic pickup)

Speed range 0-50000 RPM

Accuracy ± 0.1% of full scale

Alarm response time<10 milliseconds

Power supply 24 VDC (10-30 VDC range)

Working temperature -40 ° C to 85 ° C

Storage temperature -55 ° C to 125 ° C

Vibration resistance 5 g (5-2000 Hz, IEC 60068-2-6)

Certified API 670, CE, UL, CSA, IEC 61508 (SIL Level 2)

Dimensions: 48.3 millimeters (height) x 177.8 millimeters (width) x 254 millimeters (depth)

Weight 0.9 kilograms

Output 4 relays (2 alarms, 2 shutdowns), analog signal (4-20 mA, 0-10 VDC)

Communication 3500 series backplane (proprietary), optional Ethernet/IP through gateway

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500/54-03-00

Application areas:

In natural gas compression plants, turbines and compressors operate at high speeds. Unexpected overspeed caused by control system failure or mechanical defects may result in blade detachment, shell rupture, or even explosion. 3500/54-03-00 continuously monitors shaft speed through proximity sensors or magnetic pickups. Once the speed exceeds the preset threshold, an alarm or shutdown is immediately triggered.

In power plants, this function is equally critical as steam turbines must maintain precise speed to avoid grid instability or mechanical damage. For engineers managing large mechanical units such as mines or paper mills, the ability of this module to track acceleration rates and zero speed conditions ensures proactive maintenance and compliance with safety regulations such as API 670.

3500/54-03-00

Related products:

BENTLY 3500/22M – Mechanical Protection Module, used for Keyphasor and Speed Measurement, suitable for synchronizing overspeed data with rotational phase analysis.

BENTLY 3500/32- Four channel displacement module, used in conjunction with 3500/54-03-00, monitors shaft position during overspeed events.

BENTLY 3500/92- Communication Gateway Module, which enables data integration with enterprise systems such as PI System and Wonderware for remote overspeed trend analysis.

BENTLY 3500/05- Rack power supply, ensuring stable power supply for 3500 series racks, is crucial for maintaining module reliability during voltage fluctuations.

BENTLY 3500/60M – Temperature monitoring module that correlates speed data with bearing temperature to identify overheating caused by overspeed or misalignment.

BENTLY 3500/15- Relay module, drives external safety devices (such as solenoid valves, circuit breakers) based on the 3500/54-03-00 signal to expand shutdown capability.

Installation and maintenance:

Before installation:

Ground the 3500 series rack to<1 ohm and connect the sensors using shielded twisted pair cables to reduce EMI/RFI interference.

Ensure that the installation gap of the proximity sensor (usually 1-2 millimeters) complies with the manufacturer’s specifications to avoid false speed readings.

Reserve adjacent rack slots for power and communication modules for heat dissipation and easy access.

maintain:

Perform loop checks using calibrated speed simulators every quarter to verify the signal integrity from sensors to modules.

Review alarm setpoints annually based on mechanical OEM recommendations, especially after major maintenance or equipment upgrades.

Update the firmware at least once a year through BENTLY AMS Suite to access new features (such as enhanced acceleration algorithm) and security patches.

Clean module vents and connectors every six months in dusty environments to prevent heat accumulation or corrosion.

BENTLY Other product models

BENTLY 84661-50

BENLTY 3500/92-04-01-01

BENLTY 3500/70-01-00(176449-09+140471-01)

BENLTY 176449-03

BENTLY 330881-28-08-120-00-02

BENTLY 330881-28-08-060-00-02

BENTLY 990-04-ХХ-01-05 165335-01

BENLTY 3500/91M 190782-01

BENLTY 3500/61 163179-02

Bently Nevada 3500/50-04-002

BENLTY 3500/25M-02-02

BENLTY 3500/42M-04

BENLTY 3500/33-01-01

BENLTY 3500/92-04-01

BENLTY 3500/45 176449-04

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 2300/20-00

BENLTY 3500/22-01-01-R0

BENLTY 3500/92-04-01-R0

BENLTY 330851-02-000-060-10-00-00

BENLTY 3500/65 172103-01 small card

BENLTY 3500/22M 288055-01 Large Card

BENLTY 3500/40M 176449-01 Large Card

BENLTY 3500/65 145988-02 Large Card

Bently 3500/54 133396-01

Bently 3500/54 286566-01

BENLTY 3500/22-01-01-00

BENLTY 3500/22-01-01-00

BENLTY 3500/92-04-01-R0

BENLTY 3500/15-05-05-R0 front and rear card set

BENLTY 3500/62 136483-01

BENLTY 330103-00-03-05-02-05

BENLTY 3500/22 288055-01

BENLTY 3500/22 288055-01 large truck

BENTLY 3500/62 136483-01 small card

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626