Description

In the pulsating core of industrial automation, where shaft speeds dictate the rhythm of turbines, compressors, and pumps, a momentary lapse in rotational oversight can unleash imbalances that ripple into catastrophic rubs, overspeeds, or outright failures. Consider a steam turbine in a cogeneration plant or a multistage compressor in LNG processing: proximity probes and magnetic pickups pulse keyphasor signals essential for phase referencing and acceleration tracking, yet generic speed inputs often drown in noise or lack the granularity for reverse rotation detection, leaving your process control vulnerable to undetected drifts that cascade into emergency scrubs and regulatory audits under API 670. This is the blind spot the Bently Nevada 3500/50M illuminates as a dual-channel tachometer module, capturing raw rotational data with unerring fidelity to feed your rack’s protective logic, ensuring high reliability for I/O signals that anchor machinery health without false triggers.

These capabilities prove crucial in environments demanding split-second stability, like variable-speed drives in refineries or hydro units with load ramps, where acceleration spikes or zero-speed stalls signal brewing issues from coupling wear to grid faults. In rack configurations I’ve troubleshot across genset arrays, operators frequently tangle with modules that muddle keyphasor timing or ignore directionality, spawning alert storms that divert teams from true threats and inflate validation cycles. The Bently Nevada 3500/50M cuts through this by conditioning inputs for clean tach pulses—up to 20 kHz—while embedding peak-hold metrics for post-event forensics, so you diagnose rotor anomalies without exhaustive recreations. In the layered demands of industrial automation, it fortifies the speed layer against transients, enabling modular expansions where signal integrity from pickups drives everything from eccentricity alarms to TSI suites, turning potential pitfalls into precise protections.

Fundamentally, the Bently Nevada 3500/50M reframes speed sensing from a reactive pulse to a proactive pulse-check, letting you harmonize operations with the assurance that rotational truths surface clearly. It’s tuned for those torque-testing junctures in process control where a few RPMs define downtime, delivering the diagnostic depth that sustains spins and safeguards spans.

- 3500/50M

- 3500/50M

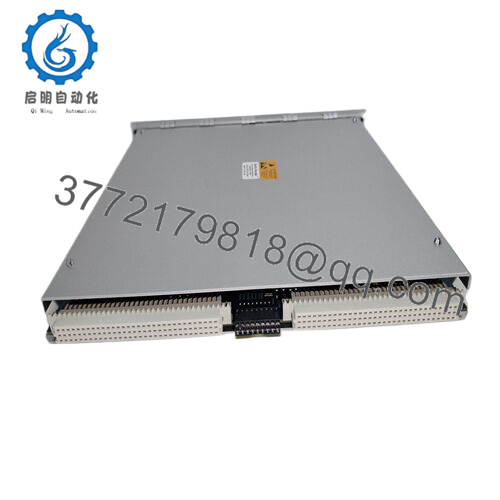

When slotting the Bently Nevada 3500/50M into a 3500 rack for comprehensive drivetrain watch, see it as the rotational compass in your monitoring mosaic, accepting dual inputs from proximitor sensors or mag pickups—each channel independently tunable for zero-crossing or pulse-per-rev modes—to derive speed, direction, and accel metrics that timestamp keyphasor events for downstream modules like vibration displacers. It plugs into full-height slots via the backplane, sourcing +18-30 VDC from rack rails while routing conditioned TTL outputs and analog recorder feeds to the system bus, bridging the field edge to core logic where FlexLogic correlates rpm with orbit plots for holistic fault trees.

Day-to-day, it converses fluidly with the rack’s TDI for setpoint broadcasts, where you configure bands via Rack Configuration software—say, notching alarms for reverse rotations above 10% threshold—while internal diagnostics scan for signal loss or overloads, latching relays that trip ESD paths or notify via Modbus to SCADA overlays without rack-wide halts. Its peak capture latches max speeds or reverse counts, resettable on command, feeding SOE logs for acceleration profiling in startup sequences. No add-on scalers; it normalizes probe gaps on ingress, with galvanic isolation per channel fending off EMI from adjacent exciters, and supports hot-insertion for maintenance swaps that preserve quorum.

In the hierarchy, it perches mid-stack—upstream of relays, downstream of transducers—enabling redundant pairings for SIL 2 schemes where one channel shadows the other, or hybrids with 3500/42M for seismic-speed fusion. For retrofits, it mates legacy keyphasors without rewiring, its buffered feeds easing historian ties. This module transcends counting turns; it temporalizes torque, crafting a process control cadence where speed’s not just measured, but mastered for enduring equilibrium.

| Specification | Details |

|---|---|

| Model Number | 3500/50M |

| Brand | Bently Nevada (Baker Hughes) |

| Type | Dual-Channel Tachometer Module |

| Input Voltage | 18-30 V DC |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | Rackmount (Full-Height Slot) |

| Dimensions | 240 x 48 x 120 mm |

| Weight | 0.6 kg |

| Interface/Bus | Backplane / TTL Outputs |

| Compliance | CE, CSA/NRTL/C, API 670, SIL 2 |

| Supported Protocols | Modbus (via rack) |

| Typical Power Draw | 8 W |

Embracing the Bently Nevada 3500/50M embeds a stratum of rotational resolve that heightens fault foresight, where dual-channel voting discerns true accel surges from pickup glitches—picture isolating a reverse spin in a pump during cooldown, halting cavitation before it scars impellers and spares the multi-day overhauls that erode margins. Sculpted for the inertial throes of heavy rotation, it clinches sustained fidelity through gap-tolerant conditioning, so probe variances don’t veil speeds, yielding the crisp phasor references that calibrate orbits and thrust without recalibration chases.

This tach also hones service precision, its latchable peaks and band alarms streamlining event reconstructions to targeted reviews rather than broad sweeps—essential in ops where proof pacts squeeze schedules thin. Amid rack constellations, it eases assembly loads by emulating legacy tachs, permitting bay growths without bus reconfigs or timing tweaks, channeling efforts to bespoke analytics like order tracking overlays. Crews draw from its status relays for workflow weave, where direction flags cue shifts intuitively, nurturing vigilance that views variances as vectors, not voids.

Deeper, the Bently Nevada 3500/50M fosters asset perpetuity, its 20 kHz bandwidth resisting drift to amplify MTBF, while tiered configs—tach-only for basics, full accel for complexes—tailor to budgets without capability cuts. The echoes extend: quelled trips that steady yields, audit-polished traces for compliance ease, and the scope to infuse ML prognostics, all buttressed by a module that doesn’t chase rpm, but choreographs it into your automation’s enduring ethos.

In gas turbine packages, the Bently Nevada 3500/50M keys shaft phasing for blade-pass alerts, weathering fuel-rich blasts to uphold critical system uptime via zero-speed confirms on startups—imperative for process control environments where accel misreads could ignite stalls and scrub loads. Its band alarming nets reverse cues amid transient hunts, reinforcing high reliability in bays pulsing with harmonics.

For petrochemical centrifugal trains, it’s racked to profile impeller speeds under surge regimes, enduring solvent vapors for continuous uptime, with peak holds logging maxes that inform wear models. The Bently Nevada 3500/50M advances modular integration, chaining channels for multi-stage oversight without central rewires.

In hydro dam Kaplan units, the Bently Nevada 3500/50M tracks runner rotations through watery fluxes, bolstering fast data cycles for direction shifts in load follows—deployed in process control environments exacting API-grade precision to avert wicket gate binds and flood risks.

3500/50 – Non-M version lacking internal barriers, suited for external termination blocks in non-hazloc zones.

3500/42M – Seismic/vibration monitor companion for fused speed-displacement in turbine TSI setups.

3500/20 – Frame interface module that hosts the 3500/50M in rack expansions for distributed gensets.

3500/05 – Card rack base for mounting the 3500/50M in standard 19-inch enclosures with power integration.

1900/47 – Compact alternative for legacy rack upgrades with basic tach functions in space-constrained cabinets.

3500/22M – Buffered output add-on for extending 3500/50M signals to remote historians or PLCs.

3701/55 – Dedicated overspeed system for pairing with 3500/50M in high-integrity shutdown paths.

As you ready the Bently Nevada 3500/50M for slotting, inventory probe types—proximitors need -24 V excitation matched, and mag pickups cap at 50 Vpp to sidestep clipping; baseline via Rack Config during dry spins to etch envelopes, amber LEDs on init cueing gap tweaks. Engage full-height clips till flush, then verify backplane via power LEDs—solid green per channel affirms pulse lock, flickers flagging bent edges. Rack thermals factor: nestle mid-bay from heat flanks, with 75mm flows unblocked in vapor-prone vaults to evade self-bias on counters.

In stride, triannual terminal probes for insulation breakdowns forestall pulse skips, notably in moist shafts—unpower, megohm to chassis, and jot shifts over 1 GOhm. Biyearly, enact band tests with a function gen to vet alarm hysteresis, archiving against thresholds; lingering offsets prompt trimpot nudges under scan. Sync yearly rack-wide baselines to hydro windows, emulating reverses to probe directionality sans flow halts, firmware syncing post-export. These anchors, distilled from spin-down diaries, hone the module’s tempo, staving the incremental fades that fuzz rotational reckoning.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626