Description

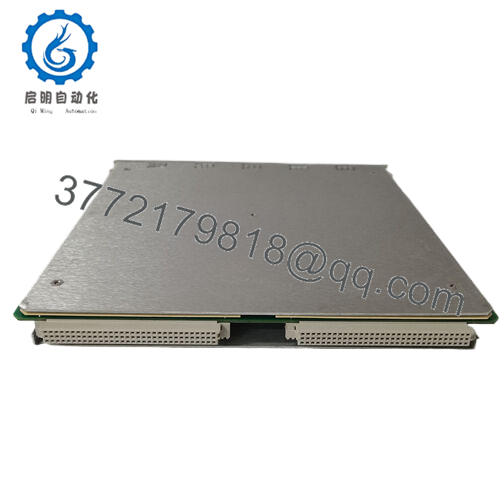

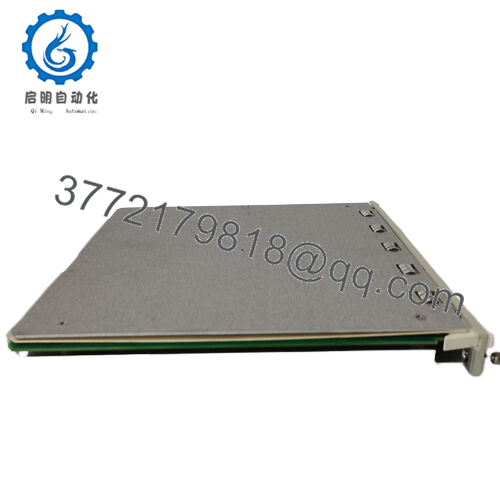

The BENTLY 3500/33 149986-01 is a half – height module that serves as a vital component within the 3500 monitoring system. It interfaces with proximity probes, which are strategically placed near the rotating shafts of machinery to detect changes in distance and vibration. The module then processes the analog signals received from these probes, converting them into digital data that can be easily interpreted by other components in the system.

350033 149986-01

Positioned within the automation stack, it communicates directly with the monitor modules in the 3500 rack. Its design is fully compatible with the 3500 series backplane system, ensuring a stable and efficient data flow. For instance, it can work in tandem with other 3500 modules, such as keyphasor modules, to provide a comprehensive view of machinery health. By integrating vibration data with other operational parameters, engineers can make more informed decisions about maintenance schedules and process adjustments. The module supports standard industrial communication protocols, allowing it to be effortlessly incorporated into control platforms from various manufacturers, including Siemens, Allen – Bradley, and others. Moreover, it comes equipped with built – in diagnostic capabilities, enabling quick identification of any issues related to signal processing or probe connectivity, which is crucial for maintaining the reliability of the industrial automation setup

350033 149986-01

Technical specifications:

Model Number3500/33 149986-01

Brand BENTLY Nevada

TypeDual – Channel Proximitor/Vibration Monitoring Module

Input Voltage18 – 32 VDC

Operating Temp Range- 40 °C to 70 °C

Mounting StyleDesigned for 3500 rack installation

DimensionsCompact, suitable for half – height 3500 rack configuration

Interface/BusCompatible with 3500 series backplane

ComplianceMeets relevant international industry standards

Supported ProtocolsStandard industrial communication protocols

Typical Power DrawOptimized for low – power consumption

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

350033 149986-01

Main features and advantages:

350033 149986-01

Application areas:

350033 149986-01

Related products:

- 3500/32 149985 – 01: A single – channel version of the module, suitable for applications where less monitoring capacity is required or for more targeted, single – point vibration monitoring.

- 3500/34 149987 – 01: Offers additional features such as enhanced signal filtering capabilities, ideal for environments with high levels of electrical noise or complex vibration patterns.

- 3500/35 149988 – 01: Designed for applications that demand more advanced diagnostic functions, providing in – depth analysis of vibration data for comprehensive equipment health assessment.

- 3300/3301: From the 3300 series, it provides similar vibration monitoring functionality but with a different form factor and potentially different compatibility requirements, suitable for systems where the 3300 platform is preferred.

- 3500/30M: A more basic model within the 3500 series, offering fundamental vibration monitoring features at a lower cost, suitable for less critical or smaller – scale industrial applications.

Installation and maintenance:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626