Description

Real-World Use & Application Scenarios

The BENTLY 3500/25 125792-01 Enhanced Keyphasor Module plays a crucial role in industrial settings where precise shaft speed and phase reference signals are essential for effective machinery condition monitoring. Typically used in power plants, petrochemical facilities, and heavy manufacturing, this module helps detect the exact alignment of the Keyphasor mark on a rotating shaft. By converting raw sensor inputs into precise digital signals, the 3500/25 125792-01 enables advanced vibration analysis, speed measurement, and phase monitoring critical for early fault detection and machine protection. This module is especially valued in industries aiming to reduce downtime and extend asset life through predictive maintenance programs, making it integral to modern automation control systems and machinery protection architectures.

- 3500-25 125792-01

Product Introduction & Positioning

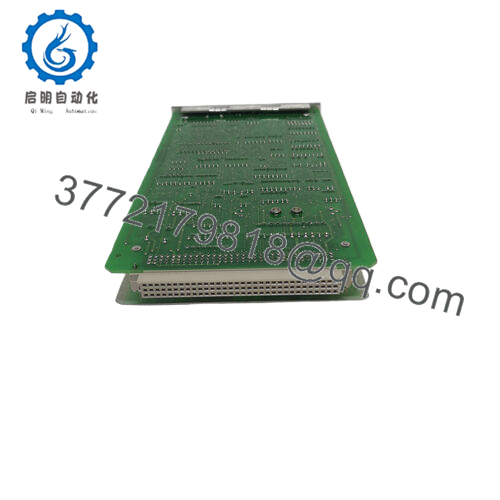

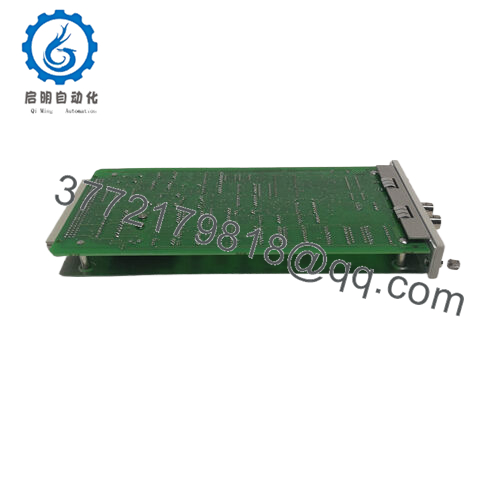

The BENTLY 3500/25 125792-01 is a half-height, two-channel Enhanced Keyphasor Module designed to provide clean, reliable Keyphasor signals to monitor modules within a Bently Nevada 3500 rack system. It processes incoming signals from proximity probes or magnetic pickups and converts these signals into digital pulses indicating once-per-turn or multiple events per shaft revolution. This processed Keyphasor output is fundamental for accurate rotational speed and phase measurements used by other monitoring modules and diagnostic equipment. Designed as a direct plug-in replacement for earlier Keyphasor modules, the 125792-01 maintains backward compatibility across form, fit, and function, simplifying upgrades in legacy systems. It integrates easily into existing 3500 Series racks and complements Bently Nevada’s broader machinery diagnostic offerings.

Key Technical Features & Functional Benefits

The 3500/25 125792-01 supports an input signal range from +0.8 V to -21 V for non-isolated I/O modules and +5 V to -11 V for isolated I/O modules. It internally limits signals exceeding these ranges, offering protection and signal stability. The module can process shaft rotational speeds from 1 to 1,200,000 counts per minute (cpm), equivalent to frequencies from 0.017 Hz to 20 kHz, accommodating multiple pulses per revolution. Signal conditioning features like automatic and manual threshold adjustments, selectable hysteresis, and signal filtering help ensure clean, precise Keyphasor outputs free from noise and distortion.

Output impedance is buffered at a maximum of 504 ohms, with power supplied to keyphasor transducers at -24 V DC with a maximum current of 40 mA per channel. Typical power consumption is a low 3.2 watts, supporting efficient rack operation. The module includes status LEDs for fault detection and communication signaling, enabling easy onsite diagnostics. Built for industrial reliability, it operates safely from -30°C to +65°C, with storage capabilities to -40°C, and handles 95% humidity non-condensing.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500/25 125792-01 |

| Brand | Bently Nevada / GE |

| Product Type | Enhanced Keyphasor Module |

| Channels | Two independent Keyphasor input channels |

| Input Signal Range | +0.8 V to -21 V (Non-isolated), +5 V to -11 V (Isolated) |

| Signal Frequency Range | 0.017 Hz to 20 kHz (1 to 1,200,000 cpm) |

| Output Impedance | 504 ohms max buffered output |

| Transducer Power Supply | -24 V DC, up to 40 mA per channel |

| Power Consumption | 3.2 Watts typical |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Dimensions (Main Module) | 119.9 mm x 24.4 mm x 256.5 mm |

| Dimensions (I/O Module) | 241.3 mm x 24.4 mm x 103.1 mm |

| Weight | 0.34 kg (Main Module), 0.46 kg (I/O Module) |

| Rack Space | 1 half-height front slot |

| Certifications | CE, UL, RoHS compliant |

| LEDs | OK, TX/RX, Fault indicators |

Related Modules or Compatible Units

3500/20 Rack Interface Module – Communication and data management module for the rack.

3500/22M Transient Data Interface Module – Supports transient waveform data in the system.

3500/15 Power Supply Module – Provides power to 3500 rack system modules including the Keyphasor.

135473-01 Keyphasor I/O Module – Alternative keyphasor I/O option offering similar functionality.

System 1™ Software – Supervisory software platform integrating Keyphasor and vibration data.

3500/94M VGA Display Module – Onsite visualization unit for condition monitoring system data.

136719-01 Earthing I/O Module – Provides earthing protection for sensor signals.

3500/25-01-02-01 Enhanced Keyphasor Module – Similar module version with updated performance.

Installation Notes & Maintenance Best Practices

Installation of the 3500/25 125792-01 involves securing the module into the appropriate half-height slot within a 3500 Series rack, ensuring stable physical and electrical connections. Signal cable routing should use shielded twisted pairs with proper grounding to minimize electrical noise interference. Front panel LEDs provide quick visual feedback on operational status and faults, aiding initial setup and troubleshooting.

Routine maintenance includes periodic verification of module outputs with diagnostic tools to confirm signal accuracy and integrity. Firmware updates should be applied as available to ensure compatibility with system, rack, and supervisory software improvements. Cleaning module connectors and monitoring ambient conditions helps prevent degradation over time, maximizing reliable continuous operation.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626