Description

The BENTLY 3500-22M 288055 -01 is an integral part of the BENTLY 3500 machinery protection system. It is typically installed within a BENTLY 3500 rack, which serves as the central housing for multiple monitoring and control modules. This module interfaces directly with vibration and displacement sensors that are strategically placed on the rotating machinery.

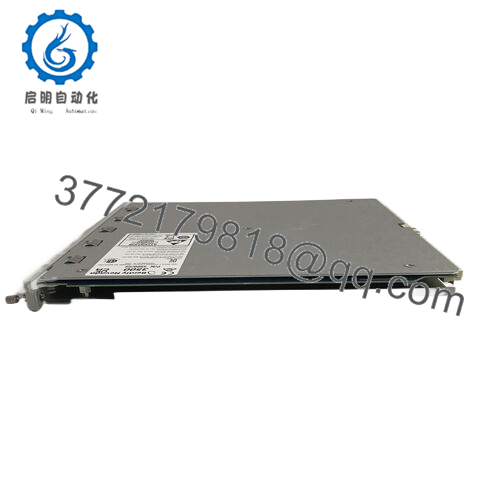

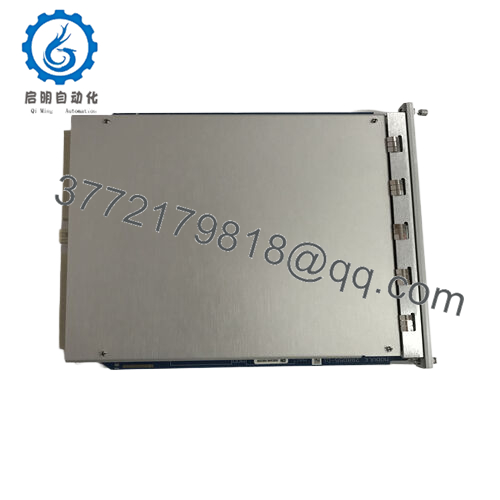

3500-22M 288055-01

For vibration measurement, it can be connected to accelerometers. These accelerometers detect the acceleration of the vibrating component, and the3500-22M 288055 -01 converts this analog acceleration signal into digital data. It then applies advanced signal processing algorithms to analyze the frequency, amplitude, and phase of the vibration. This analysis helps in differentiating between normal operational vibrations and abnormal vibrations that could indicate a problem. For displacement measurement, the module works in tandem with proximity probes. These probes use electromagnetic fields to measure the distance between the probe tip and the target surface on the rotating machinery. The module processes the signals from the proximity probes to determine the displacement of the component.

The data processed by the 3500-22M 288055 -01 is then transmitted to other components within the BENTLY 3500 system. It provides essential input for the system’s alarm and shutdown logic. If the measured vibration or displacement exceeds pre – set thresholds, the module sends signals to the alarm units, which in turn notify plant operators. It also interfaces with data acquisition units, allowing for long – term data storage and trending analysis. This historical data can be used for predictive maintenance purposes, as trends in vibration and displacement over time can reveal the gradual degradation of machinery components. In the overall industrial monitoring and control system, the 3500-22M 288055 -01 acts as a key sensor – to – system interface, ensuring that the health of rotating machinery is continuously and accurately monitored.

3500-22M 288055-01

Technical specifications:

Model Number3500-22M 288055 -01

Brand BENTLY

Type Vibration and Displacement Monitoring Module

Input SignalsFrom accelerometers (for vibration) and proximity probes (for displacement)

Signal ProcessingAdvanced algorithms for frequency, amplitude, and phase analysis

Output InterfaceCommunicates with other BENTLY 3500 modules via system backplane

Measurement AccuracyHigh – precision measurement of vibration and displacement

Input Voltage24V DC (from system power supply)

Operating Temp Range- 10°C to + 55°C (14°F to + 131°F)

Mounting StyleRack – Mounted (compatible with BENTLY 3500 racks)

Communication ProtocolsSupports standard industrial communication protocols for data transfer within the system

ComplianceCE, UL 61010 (suitable for industrial use)

Data ThroughputHigh – speed data transfer to enable real – time monitoring

Data StorageOn – board buffer for short – term data storage (configurable)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500-22M 288055-01

Main features and advantages:

3500-22M 288055-01

Application areas:

- Power Generation: In thermal power plants, the 3500-22M 288055 -01 is used to monitor the vibration of steam turbines. By continuously measuring the vibration of turbine blades, it can detect issues such as blade erosion, misalignment, or unbalance. In hydroelectric power plants, it monitors the displacement of generator rotors. Any abnormal displacement could indicate problems with the bearings or alignment, which, if not addressed, could lead to power generation inefficiencies or equipment failure.

- Oil and Gas: In oil refineries, the module is crucial for monitoring the vibration of pumps and compressors. Pumps are used to transfer various fluids, and excessive vibration can indicate issues with the impellers or bearings. Compressors, on the other hand, require precise displacement monitoring to ensure the proper sealing and operation of pistons. In gas processing plants, it helps in maintaining the integrity of high – speed centrifugal compressors by detecting any vibration – related problems promptly.

- Manufacturing: In automotive manufacturing plants, the 3500-22M 288055 -01is used to monitor the vibration of robotic arms. Precise control of vibration is essential to ensure accurate assembly operations. In textile mills, it monitors the displacement of spinning machines. Any deviation in displacement can affect the quality of the yarn being produced.

3500-22M 288055-01

Related products:

BENTLY 3500 – 23M 288056 – 01: This is a more advanced version of the vibration and displacement monitoring module. It offers additional features such as enhanced signal filtering capabilities and more complex data analytics. It is suitable for applications where extremely high – precision monitoring and in – depth analysis of vibration and displacement data are required, such as in high – tech manufacturing processes or research facilities with sensitive rotating equipment.

BENTLY 3500 – 21M 288054 – 01: A more basic version of the module with fewer input channels and less advanced signal processing features. It is designed for less demanding applications where the budget is a primary concern and the need for high – volume data processing or complex monitoring requirements is not significant. This could be suitable for small – scale industrial setups or simple machinery where the level of risk associated with equipment failure is relatively low.

3500-22M 288055-01

Installation and maintenance:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626