Description

Real-World Use & Application Scenarios

In the realm of industrial machinery protection, reliable data collection and communication integration are vital for maintaining asset health and ensuring uninterrupted operation. The BENTLY 3500-20 Rack Interface Module is a cornerstone in environments such as petrochemical plants, power generation facilities, and heavy manufacturing where continuous vibration monitoring is critical. It serves as the primary communication gateway within the Bently Nevada 3500 Series machinery protection system, enabling static and dynamic data transfer from vibration monitors and transient data interfaces. Industries facing the challenges of harsh operating conditions, electrical noise, and demanding safety requirements rely on this module to bridge sensor data with central processing or control systems. This makes the BENTLY 3500-20 invaluable in control systems requiring high fidelity data exchange, remote diagnostic access, and simplified rack configuration management. Its application extends to systems where compliance with API 670 machinery protection standard is mandated, ensuring equipment reliability, timely fault detection, and operational safety.

- 3500-20

Product Introduction & Positioning

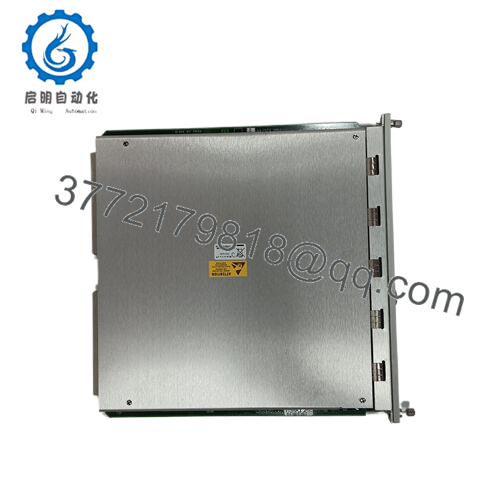

The BENTLY 3500-20 is a Rack Interface Module (RIM) designed by Bently Nevada as part of the 3500 Series condition monitoring system. Positioned in the first slot of the 3500 rack, it acts as the backbone communication hub for the entire system rack. It interfaces with proprietary Bently Nevada protocols to collect machine condition data from various monitoring modules and transmit it to critical processing units or external software like System 1™. The module supports both RS232 and RS422 serial communications, facilitating flexible data rates up to 38.4 kilobaud. While the RIM does not participate directly in the vibration monitoring path, it provides vital functions such as rack configuration, event and alarm management, and health diagnostics. The 3500-20 enhances system scalability by permitting daisy chaining multiple racks for larger installations. Designed for easy integration and straightforward maintenance, the BENTLY 3500-20 empowers engineers with seamless rack-level communication management in demanding industrial automation architectures.

Key Technical Features & Functional Benefits

The BENTLY 3500-20 boasts efficient power consumption averaging 4.75 watts, minimizing heat generation and prolonging rack component lifespan. Its operating temperature range spans from -30°C to +65°C, allowing it to comfortably function in rugged industrial environments. Multiple front panel LEDs provide clear status indications such as OK operation, data transmission, trip multiply state, and configuration validity, equipping maintenance personnel with fast diagnostics at a glance.

The integrated OK relay outputs enable users to build custom alarm logic by selecting normally open or normally closed contacts, rated for 5 amps at 24 volts DC or 120 volts AC. This capability facilitates direct integration with on-site alarm systems or safety interlocks, improving proactive fault response. The module supports Bently Nevada’s proprietary communication protocol, allowing reliable data transfer and configuration operations over RS232 or RS422 communication standards with cable distances up to 30 meters (RS232) or 1200 meters (RS422). The 3500-20 Rack Interface Module’s modular design fits standard 3500 Series racks with compact dimensions of approximately 242 mm height, 24.4 mm width, and 242 mm depth. Its durable construction, including epoxy environmental sealing, ensures longevity and resistance to industrial contaminants.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500-20 |

| Brand | Bently Nevada / GE |

| Product Type | Rack Interface Module |

| Power Supply | 18 to 36 VDC |

| Power Consumption | 4.75 Watts (typical) |

| Communication | RS232, RS422 serial communications |

| Data Rate | Up to 38.4 kilobaud |

| Operating Temperature | -30°C to +65°C (-22°F to 149°F) |

| Storage Temperature | -40°C to +85°C (-40°F to 185°F) |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 241.8 mm (9.50 in x 0.96 in x 9.52 in) |

| Weight | 0.91 kg (2.0 lbs) |

| Relay Outputs | OK relay, Normally Energized (5A @ 24V DC/120V AC) |

| Protocol | Bently Nevada proprietary |

| Environmental Protection | Epoxy sealed |

| Certifications | CSA/NRTL Class I Division 2 |

Related Modules or Compatible Units

3500-22M Transient Data Interface Module – Works alongside the 3500-20 to handle transient waveform data for advanced diagnostic applications.

3500/15 Power Supply Module – Provides regulated power to the 3500 Series rack housing the 3500-20.

3500/32M or 3500/33 Relay Modules – Offer alarm relay outputs customizable with the 3500-20 for system-wide fault annunciation.

3500/25 Keyphasor Module – Optional module that coordinates shaft speed and phase monitoring with the 3500-20.

3500/21M Standard Transient Data Interface Module – Earlier transient data module compatible with the 3500-20 rack system.

System 1™ Software – Integrates data from the 3500-20 enabled rack system for comprehensive asset condition monitoring.

3500/05 Rack – The physical rack enclosure that houses the 3500-20 and associated 3500 Series modules.

3500/94M VGA Display Module – Optional display interface used with the 3500-20 rack system for onsite visualization.

Installation Notes & Maintenance Best Practices

Proper installation of the BENTLY 3500-20 requires placement in slot one of an authorized 3500 Series rack where it can serve as the communication controller. Ensure power and communication cables meet manufacturer specifications for voltage, shielding, and length limits to maintain signal integrity. Grounding practices are critical to prevent electromagnetic interference that could degrade communication reliability. The module’s epoxy sealed design aids in protecting against dust and moisture but should be installed in an environment kept within temperature and humidity ratings.

Regular maintenance involves monitoring the front panel LED indicators to verify correct operational status and communication activity. Periodic testing of the OK relay output for proper alarm signaling is recommended. Firmware and configuration backups should be routinely performed via the communication interface to safeguard against data loss. Cleaning ventilation areas and inspecting connectors will help prolong module life and avoid unexpected failures. The 3500-20 has no direct impact on critical monitoring paths, allowing cleaning or troubleshooting without affecting vibration data acquisition modules.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626