Description

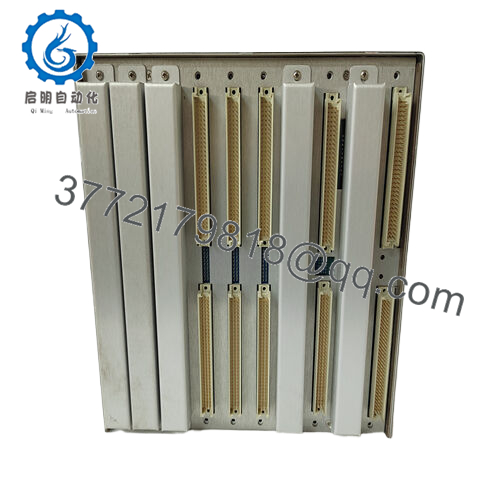

The BENTLY 3500-05-02-04-00-00-00 serves as the “brain” of the 3500 system, receiving data from up to 16 connected I/O modules (such as vibration transducers or temperature probes) via the system backplane. Its advanced processing engine analyzes incoming signals against user-defined thresholds—detecting anomalies like excessive vibration amplitudes or temperature spikes—and generates alerts when parameters exceed safe limits.

3500-05-02-04-00-00-00

Positioned at the core of the 3500 rack architecture, it interfaces with display modules, relay modules, and communication gateways to distribute processed data. It supports dual redundancy, allowing a backup module to take over instantly if the primary unit fails—critical for uninterruptible processes like nuclear power generation. Compatible with protocols such as MODBUS TCP and OPC UA, it feeds data to SCADA systems or cloud-based analytics platforms, enabling remote monitoring. This modular design ensures scalability: adding more sensors or expanding to new machinery 只需 integrating additional I/O modules, with the 3500-05-02-04-00-00-00 handling the increased data load without performance degradation.

3500-05-02-04-00-00-00

Technical specifications:

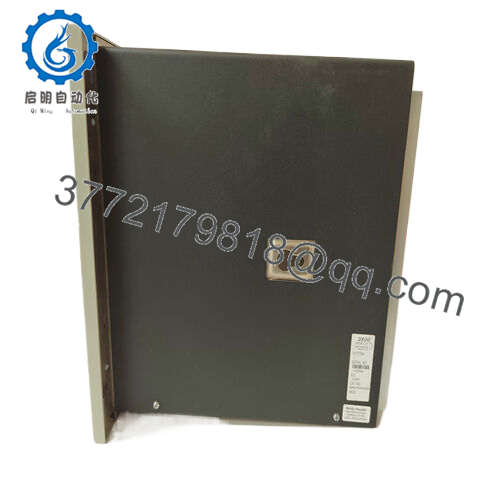

Model Number3500-05-02-04-00-00-00

BrandBENTLY

TypeCentral Processing Module

Processing Capacity16 I/O module connections

Input Voltage24V DC (from 3500/15 Power Supply)

Operating Temp Range0°C to +60°C (32°F to +140°F)

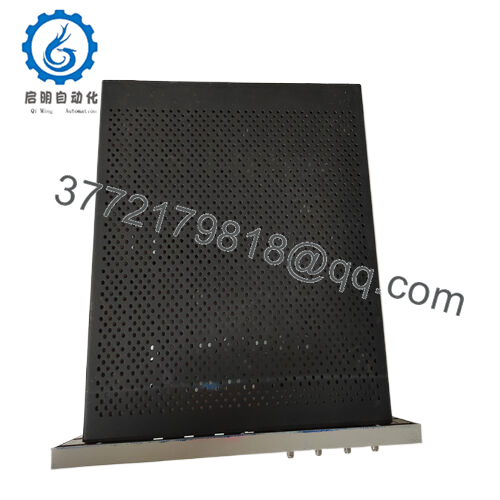

Mounting Style3500 Rack-Mounted

Dimensions170mm x 85mm x 230mm (WxHxD)

Weight1.2 kg (2.65 lbs)

Interface/Bus3500 System Backplane

ComplianceCE, UL 508, ATEX/IECEx Zone 2

Supported ProtocolsMODBUS TCP, OPC UA, Ethernet/IP

Typical Power Draw15W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500-05-02-04-00-00-00

Main features and advantages:

3500-05-02-04-00-00-00

Application areas:

3500-05-02-04-00-00-00

- 3500-05-02-08-00-00-00 – Supports 32 I/O modules for larger systems (e.g., refineries with multiple units).

- 3500-05-01-04-00-00-00 – Single-redundancy version for less critical applications (e.g., food processing lines).

- 3500/20 – Legacy processing module, still supported but with slower data throughput.

- 3500/92 – Communication gateway, pairs with 3500-05-02-04-00-00-00 to extend cloud connectivity.

- 3500/15 – Power supply module, required to operate the 3500-05-02-04-00-00-00 in 3500 racks.

- 3500/42M – Temperature input module, integrates seamlessly for multi-parameter monitoring.

3500-05-02-04-00-00-00

Installation and maintenance:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626