Description

Real-World Use & Application Scenarios

Industrial plants and critical machinery environments require reliable, modular infrastructure to support comprehensive condition monitoring systems. The BENTLY 3500-05-02-04-00-00-00 System Rack is a foundational component used across industries such as power generation, oil and gas, petrochemical, and heavy manufacturing. It provides a secure and organized platform for mounting all Bently Nevada 3500 Series monitoring modules, power supplies, and system accessories. This rack is essential in environments where asset integrity and downtime minimization are critical priorities. The 3500-05-02-04-00-00-00 facilitates proximity sensor installation for monitoring machinery vibration, rotor position, temperature, and other vital parameters. Its robust construction addresses challenges of harsh industrial conditions—such as vibration, temperature fluctuations, and contamination—while ensuring modules communicate seamlessly to capture machine health data real-time. This system rack is applicable in control systems demanding high reliability and compliance with machinery protection standards like API 670, supporting continuous online monitoring and predictive maintenance initiatives.

Product Introduction & Positioning

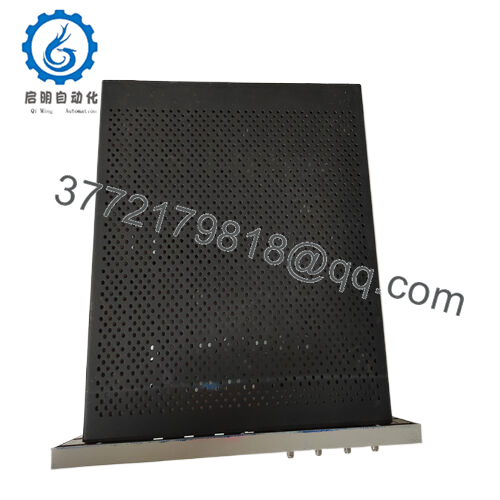

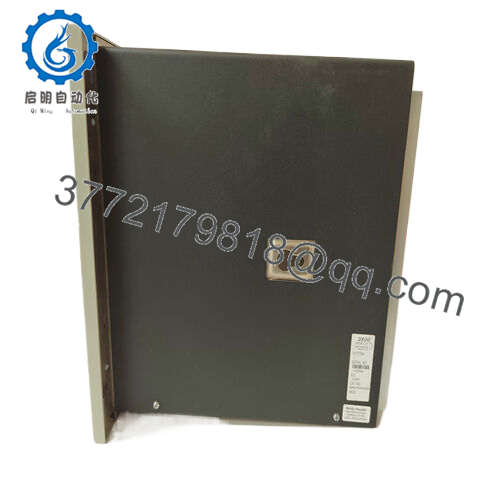

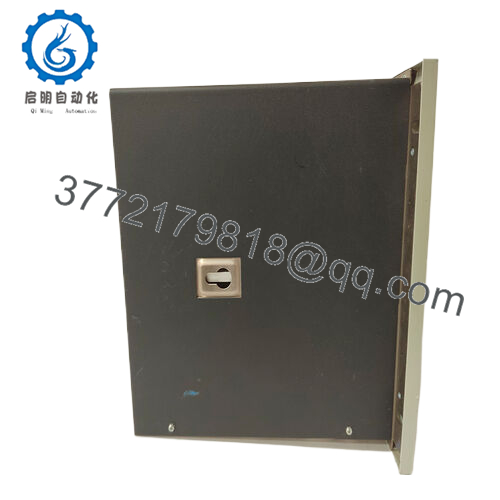

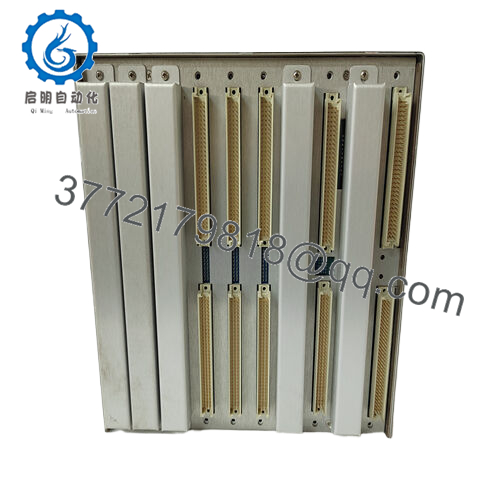

The BENTLY 3500-05-02-04-00-00-00 is a standard 3500 Series instrument rack engineered to house Bently Nevada’s suite of condition monitoring modules and power supplies. Available in multiple mounting styles—such as 19-inch EIA rack mount, panel cutout mount, and bulkhead mount—this rack offers flexibility to fit a variety of installation layouts and spatial constraints. It features 14 module slots (in the full-size configuration) for versatile system expansion, while mini-rack variants cater to smaller monitoring setups. The rack organizes and mounts all key monitoring and system modules securely, providing backplane connectivity to establish data communication pathways essential for system operation. Engineers value the 3500-05-02-04-00-00-00 for its compatibility with internal or external intrinsic safety barriers, supporting installations in hazardous areas. Its modular design maximizes ease of maintenance and system scalability, pivotal for asset reliability programs across plant lifecycles.

- 3500-05-02-04-00-00-00

Key Technical Features & Functional Benefits

Constructed to industrial-grade standards, the 3500-05-02-04-00-00-00 rack is available in both standard-depth (349 mm) and shallow bulkhead mount (267 mm) versions, accommodating diverse mechanical integration needs. It supports installation of power supplies and transient data interface modules in dedicated left-backplane slots, ensuring proper power distribution and data acquisition flow. The rear or top module mount options allow flexible wiring access, simplifying field wiring and maintenance activities. The rack is engineered to support a wide ambient temperature range and environmental conditions typical to demanding industrial sites.

Robust mechanical construction featuring corrosion-resistant materials and optional NEMA 4 or 4X weatherproof housings provide protection against dust, moisture, and corrosive elements. The rack’s architecture facilitates efficient ventilation and natural convection cooling, preserving electronic module longevity. Comprehensive diagnostics and system monitoring are enabled through integration with Bently Nevada System 1™ software, leveraging data communication handled through modules housed within the rack. The 3500-05-02-04-00-00-00 ensures reliable mechanical and electrical support, which is critical in uptime-critical industrial applications requiring precise machinery protection and condition monitoring.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500-05-02-04-00-00-00 |

| Brand | Bently Nevada / GE |

| Product Type | Instrument Rack (System Rack) |

| Module Slots Available | 14 (full-size rack) |

| Mounting Styles | 19″ EIA rack, Panel cutout, Bulkhead mount |

| Rack Depth | 349 mm (standard), 267 mm (bulkhead) |

| Environmental Protection | Optional NEMA 4/4X housings |

| Compatible Power Modules | 3500/15 Power Supply modules |

| Compatible System Modules | All 3500 Series Monitoring modules |

| Operating Temperature | -30°C to +65°C |

| Dimensions (HxWxD) | Varies by mounting style; approx 482.6 mm x 441.96 mm x 349 mm |

| Wiring Access | Rear or top wiring options |

| Weight | Dependent on rack style; approx. 10–15 kg (empty) |

| Safety Features | Supports intrinsic safety barriers for hazardous areas |

| Certifications | CSA/NRTL, ATEX options possible |

Related Modules or Compatible Units

3500/15 Power Supply Module – Power module that supplies DC power to modules installed in the 3500-05-02-04-00-00-00 rack.

3500-20 Rack Interface Module – Communication backbone module installed in the rack facilitating data traffic.

3500/22M Transient Data Interface Module – High-speed transient waveform capture module compatible with the rack system.

3500/32M or 3500/33 Relay Modules – Provide alarm relay functions integrated in the rack monitoring system.

3500/25 Keyphasor Module – Provides shaft speed and phase reference input within the rack system.

3500/94M VGA Display Module – Optional display interface for onsite rack data visualization.

Intrinsic Safety Barriers – Devices installed with the rack modules to guarantee safe operation in hazardous environments.

System 1™ Software – Advanced condition monitoring and diagnostic software integrating data from all rack modules.

Installation Notes & Maintenance Best Practices

Installing the 3500-05-02-04-00-00-00 rack requires ensuring the mounting surface and location provide adequate support and clearance for wiring access and heat dissipation. Select the mounting style suitable for structural and spatial constraints—whether panel, rack rail, or bulkhead mount. When installing in hazardous areas, confirm compatibility with intrinsic safety barriers and follow all applicable safety and electrical codes. Proper grounding and shielding of cables reduce electromagnetic interference impacting sensitive monitoring signals.

Maintenance involves routine cleaning to prevent dust and condensate buildup, which could affect module cooling and connections. Visual inspections of module seating, wiring integrity, and LED status indicators should be scheduled. Ensure power supplies and rack interface modules are functional through system diagnostics. Firmware and configuration backups of modules residing in the rack are recommended during maintenance to preserve system state. Modular design allows quick replacement of faulty components, minimizing monitoring system downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626