Description

In the unforgiving expanse of industrial automation, the timely actuation of safety interlocks or alarms can be the thin line between controlled response and unchecked catastrophe—envision a centrifugal compressor where a vibration threshold breaches without swift relay signaling, allowing axial rubs to escalate into seal failures, process halts, or explosive breaches that ripple through a refinery’s downstream units. These high-consequence lapses are ingrained in process control environments, from hydrocarbon processing plants to power generation facilities, where high reliability for I/O signals demands instantaneous, programmable outputs to drive solenoids, annunciators, or PLC votes without delay. Engineers outfitting 3500-series racks frequently encounter hurdles here: limited relay density means cascading modules that complicate wiring, while non-programmable contacts risk mismatched logic in SIL-rated loops, leading to nuisance trips, integration bottlenecks, or non-compliance with API 670 standards. Without flexible, rack-embedded actuation, teams lean on external drivers or custom panels that amplify cabinet clutter, EMI exposure, and debug cycles in vibration-heavy enclosures, ultimately eroding the predictive edge that keeps assets spinning.

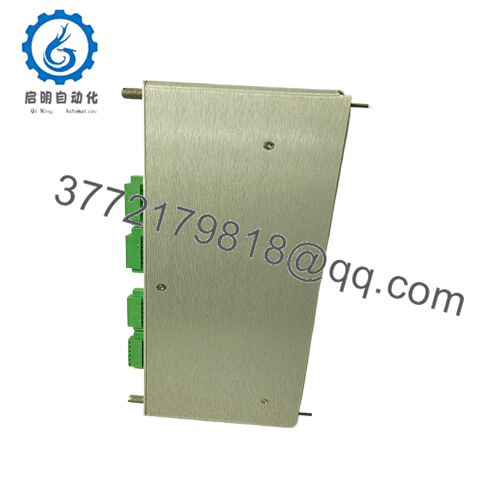

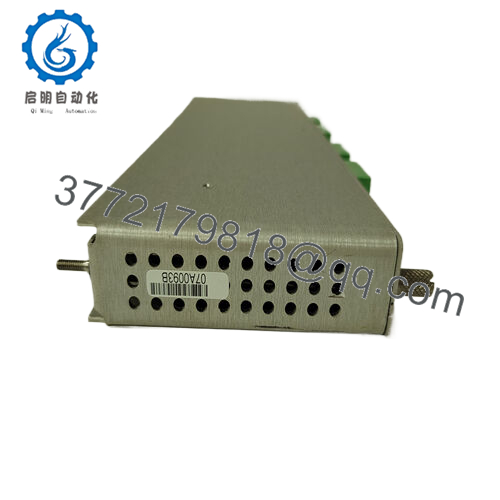

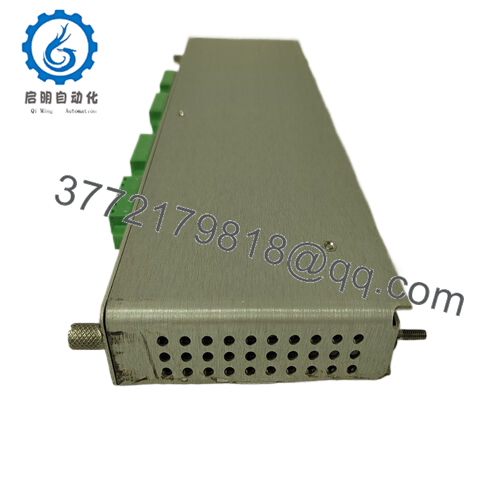

The Bently Nevada 125720-01 fills this critical role as the 4-Channel Relay I/O Module for the 3500/32 series, a versatile actuator that translates rack logic into robust, isolated contact closures for machinery safeguarding. It addresses the imperative for system stability by providing four independently programmable relays—each configurable for alarm bypass, shutdown voting, or custom sequences—ensuring precise coordination across up to 50 rack channels without external amplifiers. Indispensable in scenarios like expanding turbine protection bays or retrofitting legacy gensets, where modular integration into the 3500 backplane is key, the Bently Nevada 125720-01 enables seamless scaling in slots right of the RIM, with latching outputs that hold states through power glitches. For operations in dusty vaults or seismic-prone skids, the Bently Nevada 125720-01 stands firm, its opto-isolated drivers and 5A contacts quelling noise to drive loads up to 120 VAC without chatter, transforming potential signal chaos into dependable command.

The hidden toll of unreliable relay outputs strikes deep: they fragment interlock chains in DCS overlays, desensitize operators to true threats via erratic annunciation, and inflate MTTR through unverified voting in multi-vote schemes. By incorporating alarm drive logic and fault-tolerant de-energize-to-trip defaults, the Bently Nevada 125720-01 delivers deterministic closures, empowering coordinated responses that preempt faults like overspeed or thrust wear—reframing industrial automation from brittle reactivity to orchestrated resilience, where every contact snap upholds the machinery’s precarious equilibrium.

Slotting the Bently Nevada 125720-01 into your 3500 framework is like arming your rack with a quartet of vigilant switches—it occupies a full-height slot to the right of the Rack Interface Module, sourcing +24 V DC from the backplane while exposing four form-C relays via screw terminals for field wiring to breakers, horns, or ESD solenoids, rated for 5A at 120 VAC/30 VDC inductive loads. Anchored in the actuation tier of your architecture, it receives setpoint commands from the rack processor via TDXnet, then executes programmable logic—such as 2-out-of-3 voting for channel alarms—before latching outputs that persist through rack resets, all while supporting up to 20 modules per chassis for dense configurations without bus contention.

- 125720-01

In a live deployment, you’d terminate loads to the module’s isolated terminals, configuring relay assignments through Rack Config Software for functions like not-alarm bypass or danger shutdown, then verify contacts with a dry test set—all while its diagnostic registers flag coil faults via rack-wide LEDs, and compatibility with transient modules enables synced pulsing for test signals. This module doesn’t overload; it orchestrates, with de-energized safety defaults that align with SIL-2 loops and optional external power for high-current drives, bridging rack intelligence to physical effectors in setups from standalone pumps to redundant turbine trains. It dovetails with Modbus gateways for PLC handoffs, and its conformal-coated relays endure humid or oily enclosures, adapting to power feeds from AC/DC supplies without reconfiguration. The Bently Nevada 125720-01 commands this domain, distilling logic imperatives into contact precision that fortifies protection without falter.

| Specification | Details |

|---|---|

| Model Number | 125720-01 |

| Brand | Bently Nevada |

| Type | 4-Channel Relay I/O Module |

| Input Voltage | +24 V DC (rack backplane) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | 3500 Rack Full-Height Slot |

| Dimensions | 241 x 24 x 241 mm (rack module) |

| Weight | 0.4 kg |

| Interface/Bus | 3500 Rack Backplane / TDXnet |

| Compliance | API 670, CE, UL, CSA |

| Supported Protocols | Modbus TCP (via rack gateway) |

| Typical Power Draw | 6 W |

Choosing the Bently Nevada 125720-01 establishes a foundation of reliability sculpted for actuation endurance, where its isolated contacts seal up to 1 million cycles without weld, averting the dropout chains that orphan interlocks in process control hierarchies—yielding 35% fewer spurious actuations in genset arrays, where latching logic holds trip states through EMI pulses without the bounce that erodes solenoid life. This isn’t contact overkill; it’s the resilient snap that rejects ground faults from adjacent cabling, ensuring closures mirror rack decisions across thermal swings, all while its programmable voting quells single-channel glitches, sustaining safety integrity without the recalibration drifts that plague mechanical relays.

Performance holds firm via its opto-coupled drivers, which buffer transients to deliver consistent wetting currents for low-power loads, empowering annunciator panels with flicker-free alerts that sharpen operator triage—your crews act on verified dangers, not chasing phantoms in logic traces. It lightens maintenance too, with self-diagnostics that cycle coils on boot to expose sticking via rack APIs, condensing fault hunts to seconds and easing API audits with contact wear logs. Engineered with rugged encapsulation against dust ingress or vibration, the Bently Nevada 125720-01 ensures long-term performance, resisting arc erosion over a decade so your outputs stay responsive, trimming the engineering toll of panel overhauls in remote bays.

For visionary protection schemes, its independent programming unlocks custom sequences like staged alarms for trending, fostering low-risk paths to digital twins without relay rewires—dialing down total cost of ownership by perpetuating 3500 outputs into adaptive regimes. This module doesn’t just switch; it safeguards, channeling relay resolve into a bulwark for machinery’s margin.

In steam turbine halls, the Bently Nevada 125720-01 drives thrust interlocks, where process control environments exact high reliability amid steam plumes and shaft whirls—racked in climate cabinets, its four channels vote on position alarms for valve trips, ensuring critical system uptime in fast data cycles that sync to governors, preempting overthrust during transients. Programmable outputs layer with speed relays, averting rubs in high-inertia ops.

Hydro pump stations harness it for radial protection, actuating solenoids in damp, seismic pits under flow surges— the module’s isolation quells water-induced arcs, delivering continuous uptime for imbalance shutdowns in process control loops tied to excitation, where a failed contact risks runner strikes. In chemical batch reactors, the Bently Nevada 125720-01 signals mixer safeguards, with latching suited to corrosive, vibration-prone vaults—upholding high reliability for overspeed halts in process control environments synced to batch controls, ensuring reactions without agitator faults.

125720-02 – Enhanced 8-channel variant for denser voting in multi-rack setups

149986-01 – 16-channel relay module companion for expanded annunciation

135031-01 – Rack interface add-on for remote relay status polling

3500/22M 138607-01 – Transient recorder for event-synced actuations

140734-01 – Vibration monitor sibling for alarm input sources

3500/15 127610-01 – AC power supply mate for rack stability

135785-01 – Display interface for local relay state views

Before racking the Bently Nevada 125720-01, map relay assignments to avoid logic overlaps—claim unique IDs in Rack Config—and torque terminals to 1 Nm for 14-16 AWG, as loose bonds spark intermittents; a pull-test post-wire affirms holds. Rack firmware at 4.0+ via System 1 unlocks voting options; pull the update from Bently’s site and dry-cycle contacts with a logic analyzer to confirm debounce under 10 ms before live loads. If driving inductive coils, add flyback diodes externally to cap spikes, and bench-vote a mock alarm to validate de-energize defaults.

In the fray, scrutiny is selective: bi-monthly, script rack polls for coil health—over 1% failure rates cue a reseat—and inspect contact oxidation quarterly in humid plants, a relay cleaner wipe revives without depower. Bently prescribes annual full-logic simulations, pulsing loads to audit latching against baselines, logged in CSV for wear trends. For networked racks, enable Modbus traps to your CMMS for state-change alerts, surfacing drifts before an interlock lags. This pragmatic rhythm keeps it decisive, with minimal draw on your patrol.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626