Description

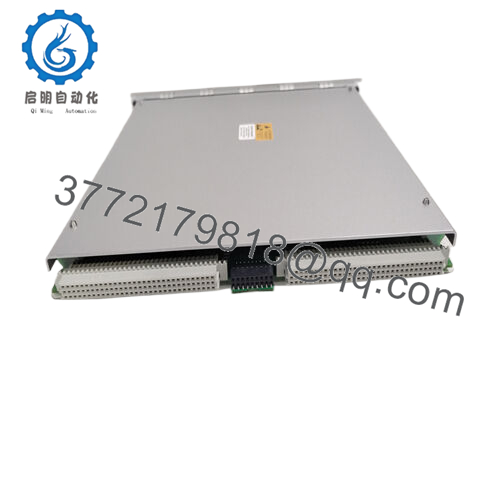

The Bentley 3500/42M is a high-performance four channel monitoring module that is deeply integrated into the Bentley 3500 series monitoring system, playing a pivotal role in industrial automation monitoring systems. It can seamlessly connect with various types of sensors such as proximity sensors, acceleration sensors, and speed sensors, accurately receiving vibration, displacement, and other signals generated during device operation. Through advanced signal conditioning and analysis techniques, the original signals are converted into intuitive and accurate monitoring data.

3500/42M

This module supports flexible programming through 3500 rack configuration software. Users can configure each channel with radial vibration monitoring, thrust position monitoring, differential expansion monitoring, eccentricity monitoring, and other functions according to their actual needs. Each monitoring channel can be paired to perform two designated monitoring tasks simultaneously, greatly enhancing the comprehensiveness and flexibility of monitoring. In addition, the Bentley3500/42M has powerful data processing capabilities, which can compare the processed signal with the user’s pre-set alarm threshold in real time. Once the monitored data exceeds the normal range, an alarm will be quickly triggered, saving valuable time for equipment maintenance.

3500/42M

Technical specifications:

Model 3500/42M

Brand Bentley Nevada

Type Four Channel Monitoring Module

Number of input channels: 4 channels

Input signal types: proximity sensor signal, acceleration sensor signal, velocity sensor signal

Measurement resolution 0.0001 inches (0.0025 millimeters)

Analog output range 4-20mA

Digital output C-type relay

Working voltage 24VDC

Typical power consumption 7.7 watts

Working temperature range -30 ° C to+65 ° C

Installation method: Rack installation (compatible with Bentley 3500 series rack)

Compliance with international standards such as CE and RoHS

Supports protocol compatibility with data transmission protocols within 3500 series systems

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

3500/42M

Main features and advantages:

Its high-precision monitoring capability can sensitively capture subtle abnormalities during equipment operation, achieve early warning of faults, help enterprises transform passive maintenance into active maintenance, and significantly reduce downtime losses caused by sudden failures. The highly integrated design and convenient installation method of this module can effectively shorten the engineering installation cycle and reduce labor costs; Good compatibility with other modules in the 3500 series also makes system upgrades and expansions easier. Moreover, the sturdy and durable construction of Bentley 3500/42M enables it to operate stably in harsh industrial environments such as high temperature, high dust, and strong electromagnetic interference, providing reliable support for long-term production of enterprises.

3500/42M

Application areas:

In the power industry, it can be used to monitor the vibration and displacement status of the steam turbine and generator rotor of the generator set, ensuring the stable operation of the power generation equipment and avoiding power supply interruption caused by equipment failure

In the petrochemical industry, monitoring the operation of large compressors and pumps can promptly identify potential equipment hazards, ensuring safe and continuous chemical production

In the metallurgical industry, status monitoring of equipment such as rolling mills and fans can help optimize equipment operating parameters and improve product quality and production efficiency.

3500/42M

Related products:

Bentley 3500/40M is a relatively basic vibration monitoring module, suitable for industrial scenarios with relatively simple monitoring function requirements;

The Bentley 3500/44M has been upgraded in terms of channel count and data processing capabilities, making it more suitable for the monitoring needs of complex equipment clusters;

The Bentley 3500/46M is more powerful in fault diagnosis and data analysis capabilities, and can meet the extremely high requirements for equipment monitoring accuracy and depth in application scenarios. These related models complement each other with Bentley 3500/42M, jointly building a rich and comprehensive product line to meet the diverse needs of different users and working conditions.

3500/42M

Installation and maintenance:

Before installing Bentley 3500/42M, it is necessary to carefully confirm the compatibility between sensor types and module input channels to ensure accurate signal integration; At the same time, it is necessary to plan the installation position of modules in the 3500 series rack reasonably, ensuring that the installation is firm and has good heat dissipation conditions; In addition, it is necessary to test the communication bus to ensure stable and smooth data transmission between the module and other system components.

During daily maintenance, it is necessary to regularly check the operating status indicator lights of the module and check whether the connecting cables between the sensors and the module are loose or damaged; Calibrate the module once every quarter to ensure the accuracy of measurement data; Arrange a comprehensive functional test once a year to promptly identify and resolve potential issues, ensuring the continuous and stable operation of Bentley 3500/42M, and providing reliable support for industrial equipment monitoring.

BENTLY Other product models

Bently 3500/22M 138607/01 Large Card 01AB Version

BENTLY 3500/22M 138607-01

BENTLY 3500/22M 138607-01AE

BENTLY 3500/22M 138607-01 large card

Bently 3500/22M 146031-01 small card

Bently 3500/22M 288055-01 Large Card

Bently 3500/22M cable

Bently Nevada 3500/33 149986-01

BENTLY 3500/22M 138607-01V

BENTLY 3500/33 149986-01

BENTLY 3500/33 149992-01

BENTLY 3500/33 149992-01 Small Card

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/70M 176449-09

Bently 3500/44M 140734-03 Large Card Version 03S

BENTLY 3500/44M 176449-03

BENLTY 3500/60-05-CN

BENLTY 3500/62 163179-03

Bently 3500/64M 176449-05

BENTLY 3500/72M

BENTLY NEVADA 3500/92 136188-02 Small Card

BENTLY 3500/72M 140734-08

BENTLY 3500/91 161204-01

BENTLY 60M500-00-00

BENTLY 3500/65-01-01(145988-02+172103-01)

Bently TK-3E 177313-02-02

Bently 1900/65A-00-01-01-01-01

BENTLY 3500/40M-01-00

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLY 86517-01-01-01-02 159840-01

BENTLY 176449-02

BENTLY 3500/22M 288055-01

BENTLY 288055-01

BENTLY 3500/15-02-02-01

BENTLY 3500/92-04-01-00 (136180-01+136188-02)

BENTLEY 3500/65 145988-02 Large Card

BENTLEY 330876-03-50-00-00

Bently 330876-03-90-00-05

Bently 3500/72M 176449-08 large card

Bently 3500/70M 176449-09 large truck

BENTLEY 3500/22M 138607-01 Large Card Old Model

BENTLY 1900/65A-01-01-03-00-01

Bently 149992-01

Bently 3500/45 176449-04 large truck

Bently 3500/42-09-05 128229-01

BENLTY 176449-04

Bently 128229-01 small card

BENLTY 24765-01-01

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626