Description

Real-World Use & Application Scenarios

The Bently Nevada 3500/42M 140734-02 Proximitor Seismic Monitor is widely used in industrial settings where real-time monitoring of machinery vibration and position is critical, such as power plants, petrochemical refineries, and heavy manufacturing. The module is specifically designed to protect rotating equipment by continuously monitoring parameters like vibration amplitude, thrust position, acceleration, and differential expansion. By providing early detection of abnormal conditions, it helps prevent equipment damage, unplanned downtime, and costly repairs. This module is especially valuable in harsh environments where maintaining operational safety and reliability is paramount, integrating seamlessly into distributed control systems (DCS) and machinery protection architectures.

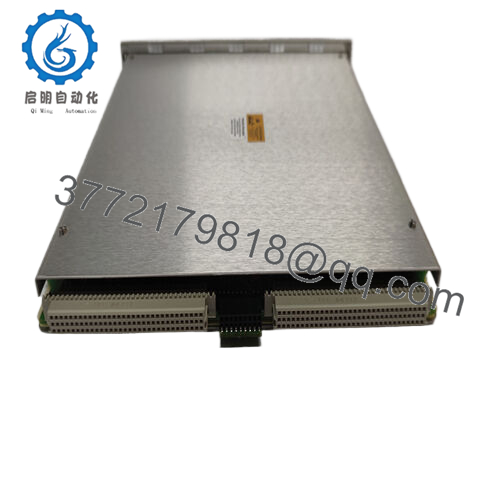

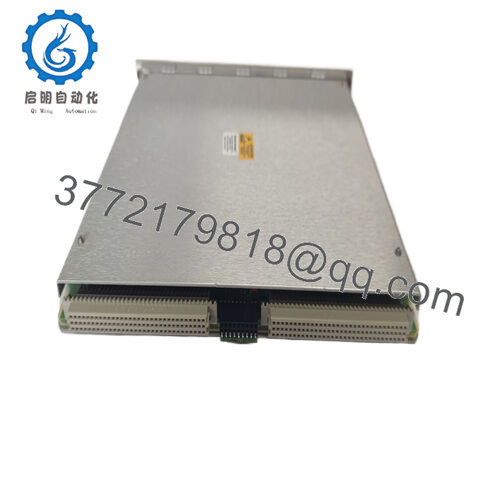

Product Introduction & Positioning

The 3500/42M 140734-02 is a four-channel vibration monitoring module that accepts input from proximity probes and seismic transducers. It conditions and processes these signals to measure vital parameters such as radial vibration, thrust position, acceleration, shaft absolute position, eccentricity, and velocity. Programmable using the 3500 Rack Configuration Software, the module delivers user-configurable alarms, including alert and danger setpoints, ensuring flexible monitoring tailored to specific machinery requirements. It fits into Bently Nevada’s 3500 Series racks and communicates critical machine health data to operators and maintenance personnel, serving as a cornerstone of effective machinery condition monitoring and predictive maintenance strategies.

- 3500/42M 140734 – 02

- 3500/42M 140734 – 02

Key Technical Features & Functional Benefits

With support for up to four input channels, the 3500/42M 140734-02 monitors vibration and position through highly sensitive signal conditioning, offering selectable sensitivity options from 3.94 mV/µm to 7.87 mV/µm. It employs advanced filtering options, including 1X and 2X vector filters suitable for a wide frequency range, providing accurate measurements aligned with machine rotational speeds from 60 to 100,000 cycles per minute.

The module operates efficiently with power consumption typically at 7.7 watts and functions reliably in industrial temperature ranges from -30°C to +65°C. It supports up to 95% relative humidity, non-condensing, making it robust for challenging industrial climates. Front panel diagnostics, including status LED indicators for operation, communication, and bypass modes, facilitate quick condition assessment and troubleshooting.

The 3500/42M 140734-02 also allows for paired channel programming, enabling operation of dual functions such as radial vibration monitoring on channels 1 and 2 alongside acceleration on channels 3 and 4. Its modular form factor, standard rack mounting, and compatibility with Bently Nevada’s diagnostic software make it a flexible and effective solution for continuous machinery protection.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 3500/42M 140734-02 |

| Brand | Bently Nevada |

| Product Type | Proximitor Seismic Monitor |

| Number of Channels | 4 |

| Input Signal Types | Proximity and seismic transducers |

| Sensitivity Options | 3.94 mV/µm or 7.87 mV/µm |

| Frequency Range | 60 to 100,000 cycles per minute |

| Power Consumption | Approximately 7.7 watts |

| Operating Temperature | -30°C to +65°C |

| Humidity | Up to 95% non-condensing |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 241.8 mm |

| Weight | Approximately 0.91 kg |

Related Modules or Compatible Units

3500/40M – Multi-channel proximitor monitor for extensive vibration and position monitoring.

3500/44M – Aeroderivative gas turbine vibration monitor module.

3500/45 – Position and expansion monitor for axial displacement analysis.

3500/50 – Tachometer module for speed and acceleration monitoring.

3500/60 – Temperature monitor complementing vibration measurement for comprehensive condition monitoring.

3500/91M – Gateway module for data communication and system integration.

System 1 Software – Bently Nevada’s analytics and visualization platform for asset health.

Installation Notes & Maintenance Best Practices

Install the 3500/42M 140734-02 securely within Bently Nevada 3500 Series racks, ensuring all connectors are seated firmly to avoid signal loss or noise. Proper cable shielding and grounding are essential to maintain signal integrity, especially in electrically noisy industrial environments. Maintain ambient environmental conditions within specified temperature and humidity limits to ensure reliable operation.

Maintenance involves routine inspection of status LEDs, verification of input signal quality, and periodic recalibration based on manufacturer recommendations. Using Bently Nevada’s configuration software supports prompt detection of changes in machine health. The module’s modular design enables hot-swapping to minimize downtime during maintenance activities, ensuring continuous protection.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626