Description

Real-World Use & Application Scenarios

The BENTLY 146031-01 Transient Data Interface I/O Module is a critical component utilized across industrial sectors such as power generation, petrochemical, and heavy manufacturing. It handles the challenging task of interfacing transient vibration and condition data from machinery protection modules to centralized monitoring systems. The module enables real-time data acquisition and communication of dynamic waveform events that are vital for predictive maintenance and fault diagnostics. The 146031-01 is specifically designed to operate within harsh industrial environments where continuous monitoring of rotating equipment like turbines and compressors is essential to avoid costly unscheduled downtime and to ensure proactive asset management. It is applicable in control systems requiring seamless integration between 3500 Series hardware and advanced diagnostic software such as System 1™, facilitating actionable insights into machinery health.

Product Introduction & Positioning

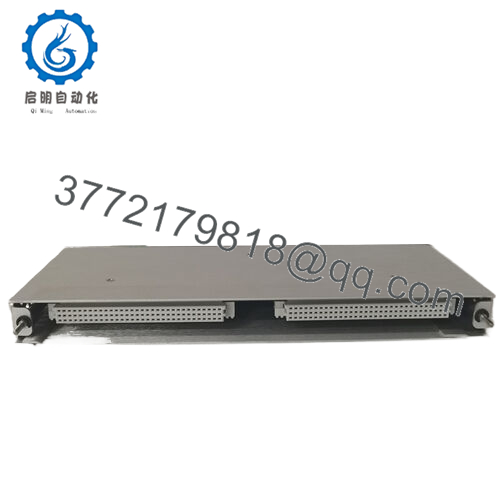

The BENTLY 146031-01 is an Ethernet I/O module forming part of the 3500/22M Transient Data Interface system. It provides 10Base-T/100Base-TX Ethernet communication capabilities, facilitating efficient and reliable data transfer between the Bently Nevada 3500 monitoring rack and external supervisory control systems or diagnostic platforms. The module is designed to work with a broad range of 3500 Series M-type monitors, such as the 3500/40M and 3500/42M, transmitting transient and steady-state vibration data essential for condition monitoring. By supporting autosensing Ethernet speeds and long cable lengths up to 100 meters for copper cabling, this I/O module offers flexibility and scalability for industrial network architectures. Its plug-in design fits into a full-height slot in the 3500 rack, providing users with an easy upgrade or replacement path within existing monitoring hardware frameworks.

- 146031-01

Key Technical Features & Functional Benefits

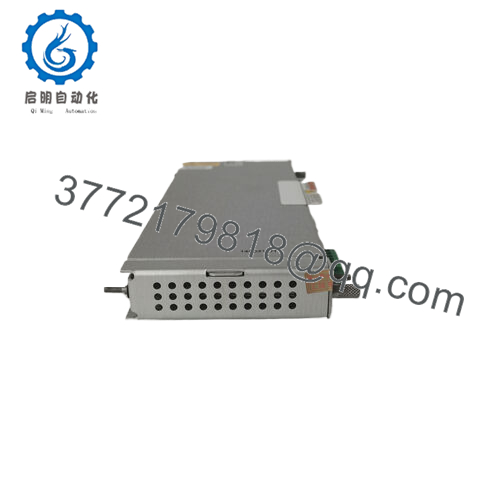

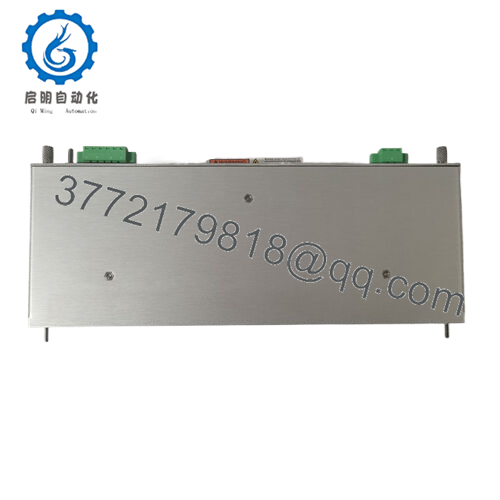

The 146031-01 features an approximate power consumption of 10.5 watts and operates within a temperature range of -30°C to +65°C, suitable for demanding plant environments. It incorporates front panel USB-B and RJ45 Ethernet connections with LEDs indicating power status, data transmission activity, rack trip multiply mode, and configuration validity, simplifying diagnostics and maintenance. The module supports the BN Host Protocol and BN TDI Protocol over Ethernet TCP/IP, ensuring compatibility with Bently Nevada’s proprietary monitoring software and third-party systems.

Its compact footprint (241.3 mm high, 24.4 mm wide, and 99.1 mm deep) and light weight (around 0.20 kg) enable straightforward integration into standard 3500 series racks without requiring additional space or special mounting considerations. The module’s robust design includes protection against dust and moisture, with a 95% non-condensing humidity tolerance, enhancing longevity and performance reliability.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 146031-01 |

| Brand | Bently Nevada / GE |

| Product Type | Transient Data Interface Ethernet I/O Module |

| Power Consumption | Approx. 10.5 Watts |

| Communication Interface | 10Base-T/100Base-TX Ethernet, autosensing |

| Protocols Supported | BN Host Protocol, BN TDI Protocol over TCP/IP |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Operating Humidity | 95%, non-condensing |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 99.1 mm |

| Weight | Approx. 0.20 kg (0.44 lbs) |

| Front Panel Connections | USB-B, RJ-45 Ethernet |

| LEDs | Power OK, Data TX/RX, Trip Multiply Mode, Config OK |

| Certifications | Meets industrial environment standards |

Related Modules or Compatible Units

3500/22M Transient Data Interface Main Module – Works in conjunction with the 146031-01 for transient data management.

3500/40M and 3500/42M Vibration Monitors – M-series modules interfacing with the 146031-01 for advanced condition monitoring.

3500/15 Power Supply Module – Provides power to 3500 series racks housing the 146031-01.

3500-20 Rack Interface Module – Central communication module facilitating rack integration and control.

System 1™ Condition Monitoring Software – Supervisory platform using data from the 146031-01 module.

146031-02 Fiber Optic Ethernet I/O Module – Fiber optic communication alternative complementing the 146031-01.

3500/04 Internal Barriers – Intrinsic safety components compatible with the 146031-01 in hazardous environments.

3500/21M Transient Data Interface Module – Legacy transient data interface system compatible with Bently Nevada 3500 series.

Installation Notes & Maintenance Best Practices

Installing the 146031-01 requires placement in a full-height rear slot of the 3500/22M rack. Proper Ethernet cabling according to industrial communication standards is essential to ensure signal quality and system stability, including use of shielded twisted-pair with RJ45 connectors. USB-B port on the front panel facilitates local configuration or diagnostics, with a recommended cable length maximum of 5 meters to avoid signal loss. Front panel LED status indicators should be monitored regularly as part of preventive maintenance to detect communication faults or configuration errors early.

Routine firmware updates and configuration backups enhance operational reliability and maintain compatibility with evolving diagnostic software versions. Keeping connectors free of dust and ensuring proper mechanical mounting prevents heat buildup and mechanical stress. Maintaining a stable ambient environment and complying with recommended electrical grounding practices helps maximize module lifespan and data transmission integrity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626