Description

Real-World Use & Application Scenarios

In hazardous industrial environments where safety and reliable sensor operation are paramount, the BENTLY 136719-01 Earthing I/O Module is a critical safeguard component. This module is widely used in petrochemical plants, power generation stations, and process manufacturing facilities where explosive gases or hazardous atmospheres may be present. It is designed to protect vibration monitoring sensor systems by converting grounding signals into industrial-standard signals that secure sensor functionality against potential harm. The BENTLY 136719-01 finds application in automated machinery protection systems that monitor turbine rotors, compressors, generators, and other rotating equipment critical to continuous industrial process control. By offering robust earthing protection and signal processing, this module addresses the real-world challenge of maintaining sensor integrity in risky environments, ensuring uninterrupted data collection for condition-based maintenance and asset reliability programs.

- 136719-01

Product Introduction & Positioning

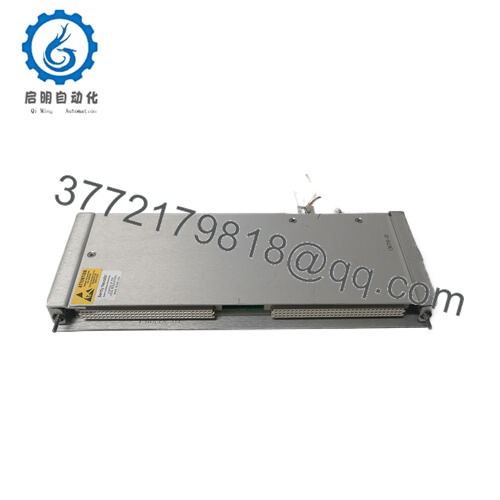

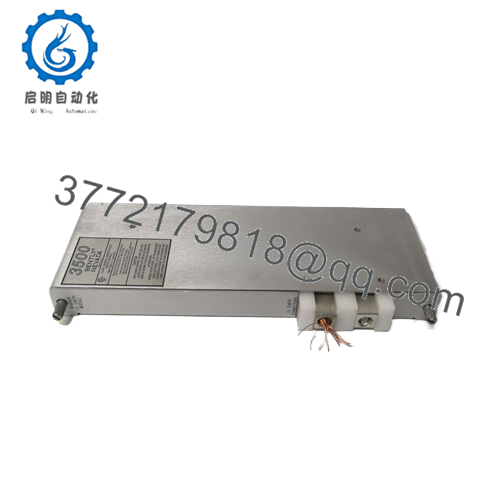

The BENTLY 136719-01 is an Earthing I/O Module within the Bently Nevada 3500 Series, engineered specifically to provide intrinsic safety by isolating and managing grounding signals from connected vibration sensors and associated hardware. Its functionality ensures safe operation by converting these grounding signals into stable, compliant outputs suitable for hazardous area installations. The module supports multiple relay outputs that can be independently programmed, facilitating customizable control and signaling schemes within the overall monitoring system. Equipped with various communication interfaces such as LAN, serial, and digital IO, the 136719-01 integrates seamlessly into large automated control networks. It is compatible with 12 to 48 VDC input power and designed for easy physical installation via rail or panel mounting, supporting industry engineers aiming to enhance sensor system safety and signal integrity in harsh operational settings.

Key Technical Features & Functional Benefits

The BENTLY 136719-01 excels in conditioning and safeguarding grounding signals with its ability to process both analog and digital inputs. It incorporates four relay outputs that engineers can program individually to implement diverse control logics or alarm functions, enhancing system responsiveness. Its communication versatility spans LAN, serial ports, and digital IO interfaces, simplifying integration with remote master stations or supervisory control and data acquisition (SCADA) systems.

Operationally, the module is built for durability, withstanding operating temperatures from -40°C to +82°C and offering an IP67 protection rating that shields it from dust and water ingress. Its anti-interference design isolates analog and digital grounds through a “busbar separate routing” methodology, effectively minimizing noise that could degrade sensor signals. The module also supports motion control applications, providing precise closed-loop feedback mechanisms ideal for servo motors and hydraulic actuators, broadening its functionality beyond mere signal conversion.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 136719-01 |

| Brand | Bently Nevada / GE |

| Product Type | Earthing I/O Module |

| Input Voltage Range | 12 to 48 VDC |

| Output Current | Maximum 10 A |

| Acceleration Frequency Range | 0 to 10,000 Hz |

| Analog Output | 4-20 mA or 0-5 VDC, max current 10 mA |

| Operating Temperature | -40°C to +82°C |

| Protection Rating | IP67 |

| Communication Interfaces | LAN, serial, and digital I/O |

| Relay Outputs | 4 programmable relays |

| Dimensions (HxWxD) | Approx. 241.3 mm x 24.4 mm x 163.1 mm |

| Weight | Approx. 0.46 kg |

| Anti-Interference Design | Busbar separate routing separating analog and digital grounds |

Related Modules or Compatible Units

3500/42M Proximitor Seismic Monitor – Complementary vibration monitoring module interacting with the 136719-01 for sensor signal conditioning.

330180-51-00 3300XL Proximitor Sensor – Standard sensor interfaced via the earthing module to condition monitoring racks.

136703-01 Internal Barrier I/O Module – Alternative protection module for hazardous area transducer systems.

3500/04 Internal Barriers – Provide intrinsic safety in conjunction with the 136719-01 in sensitive installations.

136711-01 I/O Module with Internal Barriers – Advanced input/output protection unit pairing with the earthing module.

System 1™ Software – Integrates data management and diagnostics for modules protected by the 136719-01.

136711-02 I/O Module – Works alongside the earthing module in comprehensive sensor protection schemes.

External Safety Barriers – Sometimes used with this module depending on installation requirements.

Installation Notes & Maintenance Best Practices

Installation of the BENTLY 136719-01 offers flexible mounting options, including DIN rail and panel mounting, enabling deployment in space-constrained control cabinets or racks. The module’s compact form factor and ingress protection rating simplify placement in harsh industrial environments. Proper grounding and wiring practices are critical, with carefully routed signal and power cables recommended to minimize electromagnetic interference. The module’s busbar separate routing design should be supported by careful cable management during installation.

Maintenance involves routine visual inspections for cleanliness and connection integrity, especially in hazardous environments where dust, moisture, or corrosive agents may accumulate. Its hot-swap capability supports maintenance or upgrades without system downtime. Regular functional tests of relay outputs and verification of communication performance ensure sustained system reliability. Firmware updates and configuration backups should be performed following manufacturer instructions to maintain compatibility with evolving diagnostic systems and control software.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626