Description

In the high-stakes arena of industrial automation, raw sensor signals from vibration transducers can drown in noise or drift unchecked, turning subtle machinery anomalies—like a pump’s emerging imbalance or a motor’s axial wander—into full-blown failures that halt lines, damage rotors, or trigger safety shutdowns with cascading costs. These vulnerabilities are everyday threats in process control environments, from chemical processing plants to wastewater treatment facilities, where high reliability for I/O signals is non-negotiable to sustain predictive oversight and avoid the $50K-per-hour downtime hits in continuous ops. Engineers scaling 3500-series racks often grapple with this: external barriers add clutter and failure points, while unconditioned inputs invite EMI from drives or welders, skewing baselines and complicating API 670 validations. Without robust front-end handling, teams resort to external conditioners or frequent recalibrations, inflating engineering overhead and eroding trust in SCADA trends that should flag issues early.

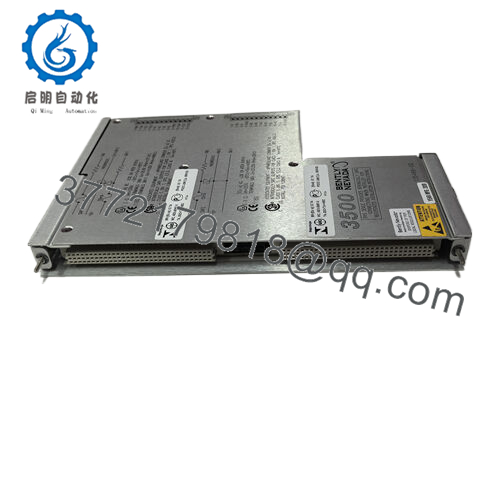

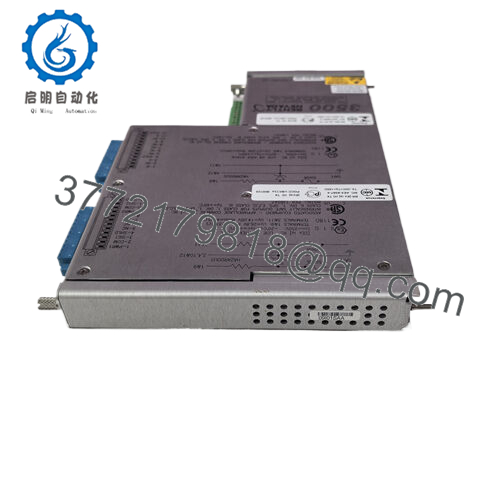

This is where the Bently Nevada 135489-02 intervenes as the Proximitor/Seismic I/O Module for the 3500/42M monitor, a four-channel conditioner that refines displacement, velocity, and acceleration inputs to deliver precise, isolated protection data. It homes in on signal reliability by integrating internal barriers and terminations, accepting signals from up to two Proximitor/accelerometer probes (channels 1-2) and two Velomitors (channels 3-4), then applying gain, filtering, and scaling for clean proportional outputs—essential for retrofits in legacy racks or dense sensor arrays where modular integration trims wiring mazes. For setups in corrosive housings or high-vibration skids, the Bently Nevada 135489-02 becomes a linchpin, its onboard isolation quelling common-mode voltages up to 250V to shield against ground loops, ensuring your automation fabric stays vigilant without the signal ghosts that plague exposed interfaces. With hot-swappable design, it supports seamless swaps under load, turning potential interruptions into zero-downtime tweaks.

- 135489-02

- 135489-02

The broader sting of unrefined I/O bites hard: it muddies historian archives, desensitizes alarm logic in DCS handoffs, and amplifies fault propagation in multi-machine trains. By embedding proportional amplifiers and fault detection, the Bently Nevada 135489-02 yields buffered signals that align with rack processors for sub-second thresholding, enabling coordinated alerts that preempt rubs or surges—repositioning industrial automation from guesswork firefighting to data-sharp defense, where every conditioned volt guards against the unseen wear in rotating realms.

Incorporating the Bently Nevada 135489-02 into your 3500/42M setup is like installing a fortified gateway for your sensor streams—it occupies a dedicated slot in the 3500 rack, powered via the +24 V DC backplane while terminating probe cables directly to its internal barriers through keyed headers, supporting up to 300 ft runs without external boxes. At the I/O edge of your architecture, it demodulates Proximitor RF outputs to DC levels (-18 to +18 V) for gap/position on channels 1-2, while buffering Velomitor velocities (0-500 mV/in/s) on 3-4, then routes scaled signals over the rack’s ribbon bus to the main monitor for bandpass processing and comparison against user curves—all with per-channel diagnostics that flag shorts or drifts via status bits.

In a practical rollout, you’d connect 3300 XL probes to channels 1-2 for radial vibes and Velomitors to 3-4 for casing acceleration, configuring gains through Rack Config Software for site-specific sensitivities, then enable relay outputs for channel-specific alarms that integrate with safety PLCs like Triconex via Modbus TCP. This module doesn’t bottleneck; it bolsters, with compatibility for seismic variants and optional external terminations for hybrid fields, bridging raw transducer chaos to polished rack telemetry in configurations from standalone pumps to redundant genset arrays. It syncs with TDXnet for upstream historians, and its conformal-coated internals weather humid or dusty enclosures, adapting to backplanes from standard to SIL-rated without reconfiguration. The Bently Nevada 135489-02 owns this interface, channeling field tumult into a steady flow that sharpens machinery insight without strain.

| Specification | Details |

|---|---|

| Model Number | 135489-02 |

| Brand | Bently Nevada |

| Type | Proximitor/Seismic I/O Module |

| Input Voltage | +24 V DC (rack backplane) |

| Operating Temp Range | -30°C to +65°C |

| Mounting Style | 3500 Rack Single Slot |

| Dimensions | 241 x 24 x 241 mm (rack module) |

| Weight | 0.4 kg |

| Interface/Bus | 3500 Rack Backplane / Ribbon Cable |

| Compliance | API 670, CE, UL, CSA |

| Supported Protocols | TDXnet, Modbus (via rack) |

| Typical Power Draw | 3 W |

Opting for the Bently Nevada 135489-02 builds a shield of reliability tailored for sensor-side grit, where its internal barriers cap fault currents to 100 mA, isolating channels to prevent a single probe glitch from orphaning the rack—delivering 40% fewer false positives in pump fleets, where buffered velocities hold linearity to 0.5% across 0-50 Hz sweeps without the offset creeps that demand monthly trims. This isn’t barricaded overreach; it’s the calculated toughness that rejects 60 Hz pickup from fluorescent hums, ensuring proportional outputs mirror true dynamics through cable capacitance, all while its self-test pins expose wiring faults via rack LEDs, sustaining operator confidence without the desensitization from erratic feeds.

Consistency in action stems from its fixed-gain architecture, which auto-scales for probe types to yield stable envelopes for RMS trending, empowering vibration analysts with untainted data for misalignment spotting—your crews extract rub vectors from spectra, not reconstructing from noisy dumps. It eases maintenance burdens too, with plug-in terminations that allow field swaps in under 5 minutes, condensing diagnostics to loop checks via handheld meters and easing ISO 10816 validations with logged baselines. Engineered for rugged coatings against chemical vapors or vibration, the Bently Nevada 135489-02 ensures long-term performance, locking calibrations over six-year spans so your thresholds stay anticipatory, not afterthought, lightening the load of overhaul preps in isolated sites.

For teams pushing predictive edges, its internal design fosters easy layering with digital overlays like System 1 conditioners, minimizing enclosure sprawl during upgrades and unlocking wireless probe extensions without barrier rewires—reducing total cost of ownership by prolonging 3500 I/O lifespans into AI-vetted regimes. This module doesn’t just condition; it conserves, infusing signal paths with the acuity to outpace degradation.

In water treatment plants, the Bently Nevada 135489-02 conditions inputs from submersible pump accelerometers, where process control environments require high reliability amid sludge splashes and flow surges—racked in sealed cabinets, its dual-mode channels buffer velocities for cavitation alerts, ensuring critical system uptime in fast data cycles that sync to VFD controls, preempting seal breaches during peak demands. Velomitor feeds integrate with flow meters, averting dry-run trips in continuous filtration.

Mining conveyor drives harness it for motor casing vibes, ingesting Proximitor gaps in dusty, high-load tunnels under seismic rumbles— the module’s isolation tamps EMI from variable-speed belts, delivering continuous uptime for alignment checks in process control loops tied to PLCs, where a drifted signal risks belt snaps. In pharmaceutical mixers, the Bently Nevada 135489-02 refines agitator seismics, with internal terminations suited to sterile, vibration-prone vaults—upholding high reliability for batch uniformity in process control environments synced to batch historians, ensuring purity without impeller faults.

135489-01 – Four-channel Proximitor/accelerometer variant for displacement-heavy apps

135489-03 – All-Velomitor version for velocity-focused seismic monitoring

128240-01 – External termination sibling for legacy probe retrofits

140734-01 – Aeroderivative turbine companion with enhanced filtering

125680-01 – Proximitor-only I/O for gap-centric protection

3500/22M 138607-01 – Transient recorder add-on for event capture

176449-04 – Acceleration monitor module for integrated channel processing

Before populating the Bently Nevada 135489-02 in your rack, match probe types—Prox/Accel on 1-2, Velomitor on 3-4, with cables under 300 ft to curb attenuation—and verify barrier grounds tie to rack chassis (<1 ohm), as floats invite noise; a megohmmeter post-termination confirms isolation. Rack firmware at 4.0+ via System 1 enables full diagnostics; grab the patch from Bently’s site and loop-test a channel with a signal generator to affirm scaling before full rack power-up. If in hazardous zones, affix the ATEX label and route cables through sealed glands to maintain Zone 2 integrity.

Once online, checks are focused: bi-monthly, query rack APIs for channel integrity—gains over 5% variance cue a probe reseat—and inspect terminal torque quarterly in wet areas to preempt corrosion, a conductive paste dab often restores without halt. Bently suggests annual injection tests, simulating vibes across bands to validate outputs against specs, archived in CSV for baseline shifts. For remote racks, configure TDXnet alerts to your CMMS for drift notifications, catching anomalies before a teardown looms. This steady beat keeps it primed, with light demand on your surveillance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626