Description

Real-World Use & Application Scenarios

In industrial environments where precise shaft speed and position monitoring are crucial, the BENTLY 135473-01 plays a vital role in supporting machinery condition monitoring and control systems. It is widely used in power plants, petrochemical facilities, and manufacturing plants where rotating equipment such as turbines, compressors, and motors require accurate shaft phase reference and speed measurement. This module is essential in predictive maintenance programs, enabling engineers to detect imbalances, misalignments, or other faults early through keyphasor signal processing. The BENTLY 135473-01 is employed within automation and control systems that demand real-time data for vibration analysis, shaft position feedback, and machine protection, helping minimize downtime and extend asset life. Its ability to transform raw sensor data into actionable signals directly addresses the challenges faced in monitoring complex rotating machinery under rigorous operating conditions.

Product Introduction & Positioning

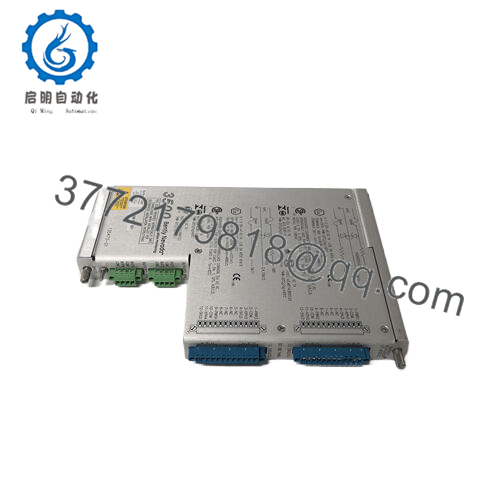

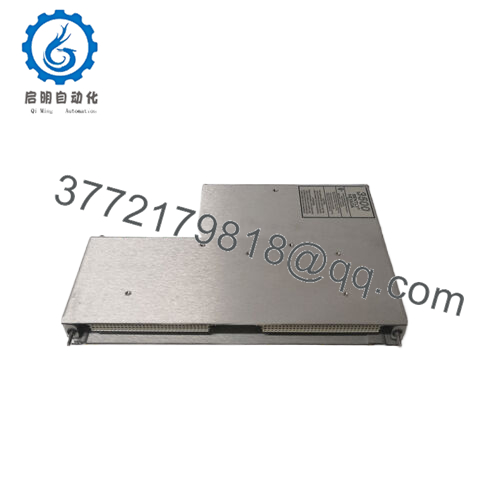

The BENTLY 135473-01 is a Keyphasor I/O Module designed as part of the Bently Nevada 3500 Series machinery protection system. It receives inputs from proximity probes, tachometers, and general-purpose digital sensors, converting these signals into digital keyphasor outputs that represent once-per-turn or multiple events per revolution of a shaft or gear. These outputs are critical for shaft speed measurement, phase referencing, and synchronization within protection and control systems. The module is designed for DIN rail mounting and integrates fully with Bently Nevada 3500 and 3300 Series control systems, enabling seamless data acquisition and system-wide synchronization. Engineers appreciate this module for its signal conditioning features such as filtering, amplification, and isolation, which ensure high fidelity and noise-free keyphasor signals vital for accurate machine diagnostics.

- 135473-01

- 135473-01

Key Technical Features & Functional Benefits

The BENTLY 135473-01 features advanced signal processing capabilities including high-pass and low-pass filtering to clean sensor inputs before conversion, thereby enhancing the accuracy of shaft position measurement. It supports nominal input voltages of 24 V DC with typical power consumption of around 3 watts, making it energy efficient for continuous operation. The module’s outputs are TTL compatible or 0-24 V DC, aligning with various control system input requirements and enabling flexible integration options.

Designed for industrial durability, it operates within temperatures ranging from -40°C to +70°C, with a compact form factor of approximately 4.9 inches by 6.2 inches by 1.5 inches and weighing around 0.5 kg. The 135473-01 is compliant with CE, UL, and RoHS standards, assuring reliability and environmental stewardship in industrial installations. Its communication interfaces support real-time integration with Condition Monitoring Systems (CMS), facilitating predictive maintenance efficiency and reducing unexpected outages.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 135473-01 |

| Brand | Bently Nevada / GE |

| Product Type | Keyphasor I/O Module |

| Input Types | Proximity Probe, Tachometer, Digital |

| Output Types | Keyphasor output (frequency or pulse), Digital signals (TTL or 0-24 V DC) |

| Signal Processing | High-pass and low-pass filtering, Amplification, Conditioning |

| Input Voltage | 24 V DC nominal |

| Power Consumption | Approx. 3 W |

| Operating Temperature | -40°C to +70°C |

| Dimensions (HxWxD) | 4.9 in x 6.2 in x 1.5 in (124 mm x 157 mm x 38 mm) |

| Weight | Approx. 0.5 kg (1.1 lbs) |

| Mounting Type | DIN rail mount |

| Certifications | CE Mark, UL Listed, RoHS Compliant |

| Communication Systems | Compatible with Bently Nevada 3500 and 3300 Series |

Related Modules or Compatible Units

3500-20 Rack Interface Module – Communication hub module compatible with the 135473-01 for rack data management.

3500/22M Transient Data Interface Module – Handles transient vibration data complementary to keyphasor signals.

330180-51-00 3300XL Proximitor Sensor – Sensor directly connected with the keyphasor module for vibration data input.

3500/15 Power Supply Module – Supplies power to the rack modules including the 135473-01.

System 1™ Software – Analytics and condition monitoring software integrating keyphasor data.

3500/25 Enhanced Keyphasor Module – Alternative keyphasor I/O solution with advanced features.

3500/94M VGA Display Module – Visual interface for onsite machinery condition visualization.

136719-01 Earthing I/O Module – Enhances signal integrity and fault protection in harsh environments.

Installation Notes & Maintenance Best Practices

The BENTLY 135473-01 is designed for DIN rail mounting within standard control cabinets or 3500 Series racks. Ensure proper grounding and twisted shielded cabling for proximity probe or tachometer inputs to minimize electrical noise and signal distortion. Regular inspection of connection integrity and cleaning of mounting surfaces helps maintain signal reliability. During maintenance, verify keyphasor output signals with diagnostic tools to confirm correct pulse timing and frequency.

Firmware and configuration settings should be backed up routinely to preserve system configurations during module replacement or upgrades. As the module operates continuously in demanding industrial environments, periodic cleaning around ventilation areas and connectors extends component life. Recalibration or alignment checks may be necessary after major equipment overhauls to ensure measurement accuracy.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626