Description

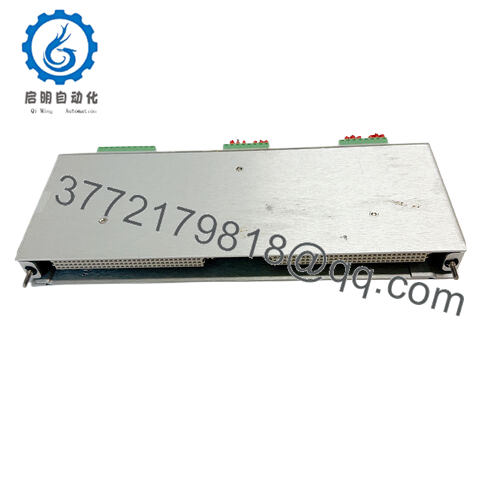

The BENTLEY 135137-01 is a high – performance vibration monitoring module designed to integrate seamlessly into the BENTLEY Nevada 3500 machinery protection system. It serves as a key link between vibration sensors, such as proximity probes and accelerometers, and the central control and analysis units.

BENTLY 135137-01

Once connected to the sensors, the module receives raw vibration signals and applies advanced signal processing algorithms to filter out noise and interference. It then converts these signals into a standardized format that can be easily understood by the 3500 system’s mainframe. The BENTLEY 135137-01 communicates with other modules in the 3500 system via the system’s backplane, ensuring smooth data transfer and integration with higher – level control systems, such as Supervisory Control and Data Acquisition (SCADA) systems.

This module supports multiple communication protocols, allowing for flexibility in data exchange and system integration. It also features built – in diagnostic capabilities, continuously monitoring its own performance and the integrity of the connected sensors. In case of any anomalies, such as a sensor failure or a deviation from normal vibration patterns, the BENTLEY 135137-01 can quickly generate alarms and send alerts to operators, enabling timely intervention to prevent equipment damage.

BENTLY 135137-01

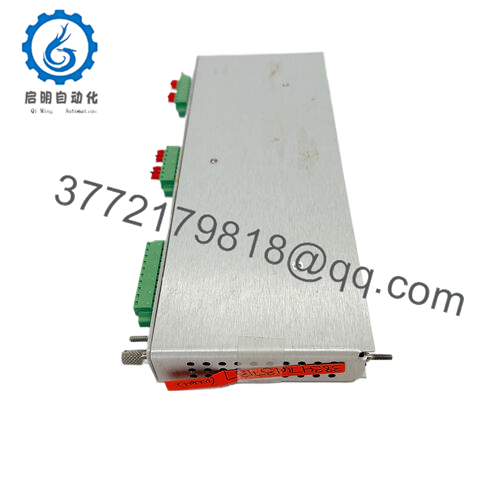

Technical specifications:

Model Number135137-01

Brand BENTLEY

Type Vibration Monitoring Module

CompatibilityBENTLEY Nevada 3500 system

Input Channels4 (can connect multiple vibration sensors)

Power SupplyDC 24V

Operating Temp Range- 40°C to + 70°C

Humidity Range0% to 95% non – condensing

Communication ProtocolBENTLEY Nevada proprietary protocol, Modbus RTU

Dimensions (WxHxD)175mm x 38mm x 105mm

WeightApproximately 0.6kg

Interface/BusConnects to 3500 system backplane

ComplianceCE, UL

Supported Protocols BENTLEY Nevada protocol, Modbus RTU

Typical Power Draw 4W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

BENTLY 135137-01

Main features and advantages:

BENTLY 135137-01

Application areas:

BENTLY 135137-01

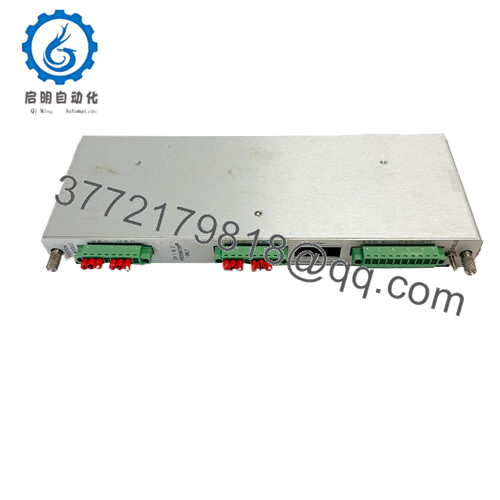

Related products:

- BENTLEY 3500/42M – A multi – channel vibration monitor with enhanced data processing capabilities, suitable for more complex monitoring requirements.

- BENTLEY 135138 – 01 – A higher – end version with additional input channels and advanced diagnostic features, ideal for large – scale industrial applications.

- BENTLEY 135136 – 01 – A more cost – effective alternative with basic vibration monitoring functions, suitable for smaller facilities or less critical equipment.

BENTLY 135137-01

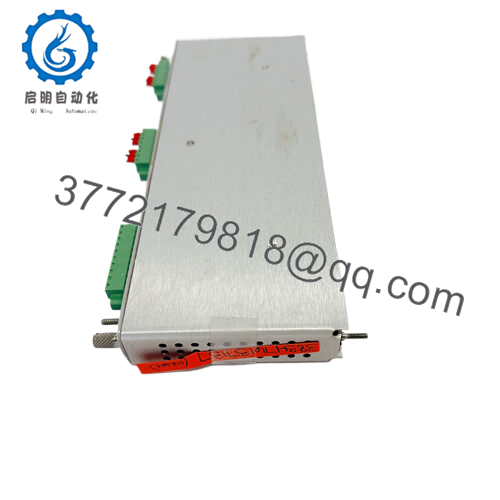

Installation and maintenance:

Before installing the BENTLEY 135137-01 module, it is essential to verify its compatibility with the existing BENTLEY Nevada 3500 system. Check the backplane configuration to ensure that there are available slots for installation. Also, confirm that the power supply meets the module’s requirements and that all necessary communication cables are properly rated.

During installation, handle the module with care to avoid any physical damage. Ensure that the connections to vibration sensors are secure and that the wiring is properly shielded to prevent electromagnetic interference. After installation, perform a thorough system check to verify that the module is communicating correctly with the 3500 system and that all sensors are functioning properly.

For ongoing maintenance, regularly review the module’s diagnostic information to detect any potential issues early. Clean the module periodically to remove dust and debris, especially in dusty industrial environments. It is also recommended to perform routine calibration of the vibration sensors connected to the module to ensure accurate data acquisition. In case of any alarms or Abnormal situation, refer to the module’s manual or contact BENTLEY’s technical support for assistance.

BENTLY Other product models:

BENLTY 161216-01

BENLTY 3500/44M 140734-03 Large Card Version 03B

Bently 3500/65 145988-02

BENLTY 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

BENLTY 330877-080-37-00

Bently Nevada 3500/15-05-05-R0

BENLTY 2300/20-00

BENLTY 3500/15127610-01 large card

Bently Nevada 3500/15-05-05-R0

BENTLY 3500/42M 176449-02 large card

BENTLY 3500/42 176449-02

BENTLY 3500/42M 176449-02 large card

Bently Nevada 3500/15-05-05-R0

BENLTY 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

Bently Nevada 3500/15-05-05-R0

BENLTY 74712-06-05-04-00

BENLTY 3500/92-01-01-00

BENLTY 3500/15 set

BENLTY 3500/92

BENLTY 3500/92-01-01-00

BENLTY 3500/42-01-02-R0

BENLTY 3500/32-02-R0

BENLTY 3500/72M

bently nevada VB8

BENLTY 3500/22M

BENLTY 3500/45

BENTLY 3500/15-05-00-05

BENTLY 3300/12/02-22

BENLTY 2300/20-CN

BENTLY NEVADA 1900/65A

BENLTY 3500/15-02-02-00

BENTLY 3500/22M

BENTLY 3500-22-01-01-00

BENTLY 3500-42-02-00

BENTLY 3500/15-05-05-00

BENTLY 3500/22-01-01-00(138607-01+146031-01)

BENTLY 3500/44M

BENTLY 3500/91M 190782-01

BENTLY 330877-080-37-00

Bently 3500/64M 176449-05

BENLTY 330106-05-30-10-02-05

BENTLY 330105-02-12-10-02-05

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626