Description

Real-World Use & Application Scenarios

When precise position monitoring of rotating machinery is paramount, the BENTLY 135137-01 emerges as an indispensable solution. This module is widely implemented in critical industries such as power generation, petrochemical manufacturing, and heavy industrial equipment maintenance. It handles position and displacement signals from sensors monitoring axial thrust, differential expansion, valve position, and machinery casing expansion. The module addresses real-world challenges of signal conditioning and alarm triggering for proximity probes, rotary position transmitters, and linear differential transformers. The BENTLY 135137-01 is used in control systems where continuous, real-time monitoring drives predictive maintenance programs, machinery protection, and operational safety. It resonates particularly in settings conforming to industrial standards like API 670, enhancing asset reliability and uptime through precise, actionable data on machine position and movement.

Product Introduction & Positioning

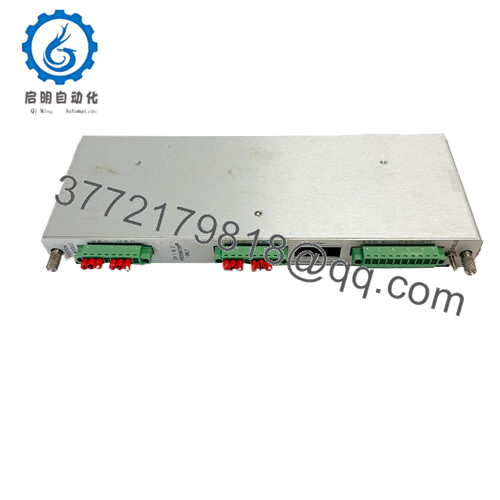

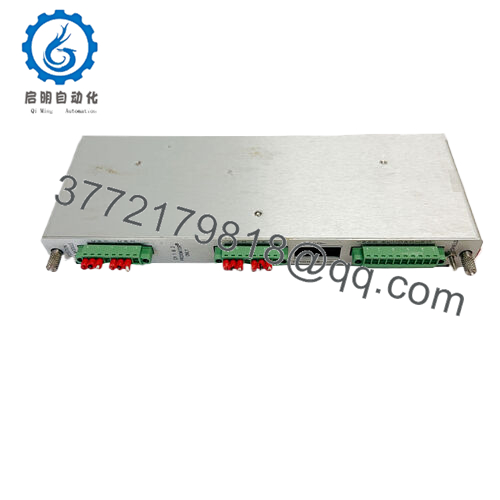

The BENTLY 135137-01 is a Position I/O module designed as part of the Bently Nevada 3500/45 monitoring system. Featuring four independent channels, it accepts and conditions inputs from multiple sensor types, including proximity transducers, rotary position transducers (RPTs), DC and AC linear variable differential transformers (LVDTs), and rotary potentiometers. This module generates internally processed signals that trigger alarms based on programmable setpoints, supporting real-time machine health assessment and fault indication. Equipped with internal terminations, the 135137-01 simplifies wiring and increases system reliability. It can be mounted on DIN rails or within system racks and integrates with Bently Nevada’s System 1™ software for comprehensive diagnostics. Engineers benefit from the module’s ability to support multiple position monitoring configurations such as axial position, differential expansion, ramp differential, case expansion, and valve position with high accuracy and programmable flexibility.

- BENTLY 135137-01

Key Technical Features & Functional Benefits

The BENTLY 135137-01 supports signal conditioning across multiple input types, offering a wide input impedance range suitable for different sensors. It provides alarm time delays configurable from 0.1 to 60 seconds, enabling tailored response timing to transient or continuous position changes. The module features multiple alarm setpoints per measured variable, allowing operators to fine-tune alert and danger thresholds for enhanced machinery protection.

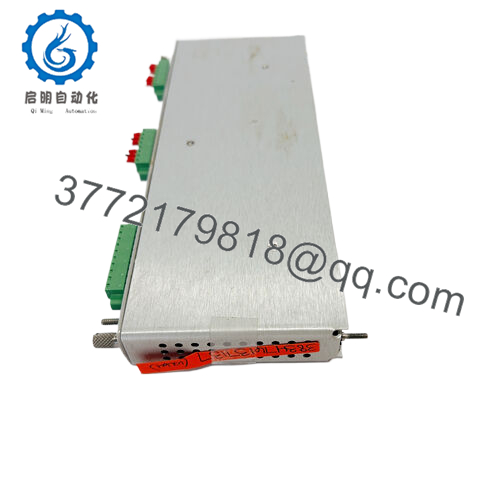

Physically, this module measures 241.3 mm in height, 24.4 mm in width, and 99.1 mm in depth, with a lightweight 0.44 kg design that eases installation. It operates reliably in temperatures from -30°C to +65°C, with a power consumption of approximately 7.7 watts. The module’s high measurement accuracy, generally within ±0.33% full-scale, supports precise monitoring tasks critical for preventing mechanical failures. Programmable sensor signal filters further enhance signal integrity to reduce noise and false alarms, contributing to elevated system reliability and operational uptime.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | 135137-01 |

| Brand | Bently Nevada / GE |

| Product Type | Position I/O Module with Internal Terminations |

| Channels | 4 independent sensor input channels |

| Supported Input Sensors | Proximity Transducers, RPTs, DC/AC LVDTs, Rotary Potentiometers |

| Input Voltage Range | 0 to 55 VDC |

| Alarm Setpoints | Programmable, multiple per measured variable |

| Alarm Time Delay Range | 0.1 to 60 seconds |

| Operating Temperature | -30°C to +65°C (-22°F to 149°F) |

| Power Consumption | Approximately 7.7 Watts |

| Dimensions (HxWxD) | 241.3 mm x 24.4 mm x 99.1 mm |

| Weight | 0.44 kg (0.97 lbs) |

| Accuracy | ±0.33% of full-scale typical |

| Mounting | DIN rail or system rack mount |

| Certifications | CE Mark, CSA/NRTL compliance |

Related Modules or Compatible Units

3500/15 Power Supply Module – Supplies power to racks housing 135137-01 and other 3500 Series modules.

3500-20 Rack Interface Module – Data communication coordinator module within 3500 Series racks.

3500/22M Transient Data Interface Module – Supports transient waveform data complementing position monitoring.

135473-01 Keyphasor I/O Module – Provides rotational speed and shaft position feedback integrated with the position I/O.

3500/25 Differential Expansion Module – Specialized module for enhanced differential expansion monitoring with the position I/O.

System 1™ Software – Integrates monitoring data and alarm management across Bently Nevada modules.

3500/94M VGA Display Module – Onsite visual interface for real-time data from the position I/O system.

136719-01 Earthing I/O Module – Provides signal conditioning and grounding protection for sensitive sensor signals.

Installation Notes & Maintenance Best Practices

Installation of the BENTLY 135137-01 requires adherence to precise wiring practices, particularly for sensor cabling to maintain signal integrity. Mount the module on standard DIN rails or compatible system racks, ensuring adequate clearance for ventilation and cable access. Verify all internal terminations for secure connections and proper polarity to prevent signal disruption. Grounding and shielding are essential to minimize electromagnetic interference in industrial environments.

Maintenance involves routine status checks of signals and alarms via software or front panel indicators. Periodic functional tests of alarm setpoints and time delay configurations are recommended to ensure responsiveness. Clean connectors and monitor environmental conditions to prevent condensation or dust accumulation that could affect performance. Firmware updates through authorized software tools keep the module optimized with the latest diagnostic capabilities.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626