Description

The AMAT 0090-07135 is primarily used in semiconductor manufacturing environments, where precise control and handling of vacuum and slurry processes are critical. This product finds application in high-tech fabrication plants that require exact and reliable components for chemical mechanical planarization (CMP) systems or vacuum systems. In these cleanroom settings, precise and stable control of vacuum or slurry pumps ensures smooth operations, consistent wafer processing, and reduced defects during production. The AMAT 0090-07135 supports demanding industrial automation tasks by managing flow rates and pressures crucial to CMP or vacuum tool performance. It helps semiconductor manufacturers achieve high throughput and maintenance of stringent process standards. Its robust design is suited for specialized tools in wafer fabrication or electronic materials processing where reliability and accurate control are non-negotiable. Applicable in semiconductor equipment and control systems, the AMAT 0090-07135 enhances equipment uptime and operational precision.

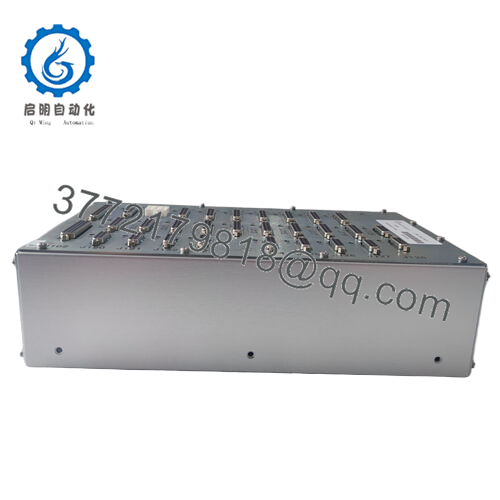

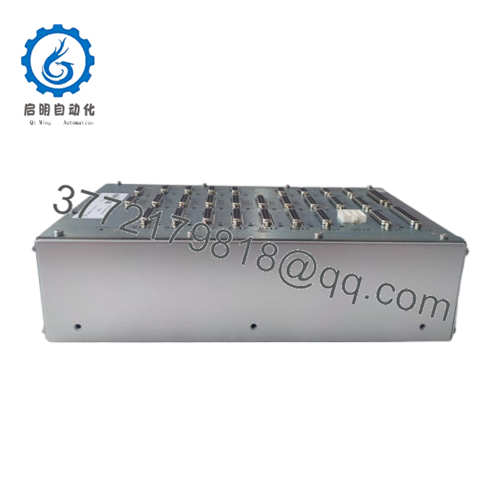

The AMAT 0090-07135 is a control component typically integrated into Applied Materials semiconductor fabrication equipment. It functions as a specialized pump motor or vacuum component, contributing to the operation of critical subsystems such as slurry distribution or vacuum generation within CMP or etch systems. This product operates on a 24 VDC input and fits compactly within the system architecture owing to its moderate dimensions of approximately 10.5 x 15 x 5 cm. It ensures efficient power delivery and torque control for stable pump operation essential to the controlled removal or movement of slurry substances. Its compatibility with other Applied Materials tool parts makes it a vital part of the automated, tightly choreographed environment in advanced semiconductor fab tools. Engineers and systems integrators appreciate the AMAT 0090-07135 for its proven integration within complex semiconductor equipment, facilitating process consistency and longevity through optimized mechanical performance.

The AMAT 0090-07135 offers high-performance capabilities necessary for semiconductor process tool reliability. With a current rating up to 2 A and an operating temperature range extending from -20°C to +85°C, this motor excels in handling the thermal stresses common in semiconductor fab environments. Its physical design balances compactness with durability to fit inside semiconductor equipment enclosures while resisting typical contamination and temperature variations. The power input and electrical specifications allow seamless integration into 24 VDC control circuits commonly found in industry-standard automation platforms. This component emphasizes low noise operation essential in ultra-clean fabrication spaces where vibration and sound can neutrally affect delicate processes. Furthermore, the AMAT 0090-07135 is engineered for extended service life with attention to minimizing mechanical wear and ensuring consistent pump motor response under prolonged operational cycles.

| Parameter | Value |

|---|---|

| Model | 0090-07135 |

| Brand | Applied Materials (AMAT) |

| Product Type | Pump Motor / Semiconductor Component |

| Input Voltage | 24 VDC |

| Current Rating | Up to 2 A |

| Operating Temperature | -20°C to +85°C |

| Dimensions (WxHxD) | 10.5 cm x 15 cm x 5 cm |

| Weight | 1.2 kg |

| Application | Semiconductor CMP & Vacuum Systems |

| Noise Level | Low Noise Operation |

- 0090-07135

Related units compatible or frequently used with the AMAT 0090-07135 include:

AMAT 0090-07200 – A related pump or motor unit with higher power rating for larger CMP tools.

AMAT 0090-07140 – A motor variant for specific slurry pump configurations within Applied Materials systems.

AMAT 0010-23716 – Control board often paired to regulate pumps like the 0090-07135.

AMAT 0090-07700 – A vacuum pump module that complements slurry processes in fabrication tools.

AMAT 0050-01010 – A sensor assembly used in conjunction with pump motors to ensure precise operation.

Prior to installation of the AMAT 0090-07135, verify the equipment enclosure allows space for the motor’s dimensions and access for maintenance. Proper electrical grounding and adherence to the 24 VDC input specifications are vital to prevent damage from voltage surges or electrical noise. During maintenance, regular inspection for wear signs on mechanical components and performance validation through monitoring current draw can preempt failures. Attention to cleanroom conditions is essential; ensure the motor remains free of particle contamination and is stored or handled with anti-static precautions. Scheduled servicing should consider motor lubrication status and replacement cycles recommended for semiconductor fab tooling to maintain precision and reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626