Description

What This Product Solves

In industrial automation environments where electrostatic precipitators (ESPs) demand precise control of high-voltage rectification and rapping sequences to optimize particle capture and minimize downtime, the Alstom EP3-E-4-EN emerges as a targeted solution for engineers grappling with inconsistent power delivery or fault propagation in multi-field ESP systems. Picture a coal-fired boiler in a power plant where voltage fluctuations from unmonitored TR sets lead to arcing or reduced efficiency, spiking emissions and compliance fines, or a cement kiln ESP where rapping failures due to sync lags cause hopper clogs and refractory wear—these headaches often root in controllers that can’t harmonize analog signals from transformers and sensors amid EMI or phase shifts in shared enclosures. This EPIC III controller module resolves them by providing adaptive high-voltage regulation with programmable setpoints for up to four fields, integrating diagnostics for arc detection and soft starting to ensure seamless operation without surges, sustaining stable outputs across 100-690 V AC ranges for reliable synchronization in real-time filtration.

It proves essential in process control applications like emissions control for utilities or industrial scrubbers, where high reliability in ESP orchestration underpins EPA or ISO 14001 compliance and seamless auto-transfer for continuous uptime. The Alstom EP3-E-4-EN interfaces via modular racks with Alstom’s EPIC III system, supporting up to four TR sets in island or grid-parallel modes with Modbus or Profibus for supervisory links, so you avoid the silos of standalone units in distributed fields. For teams retrofitting legacy Lurgi or Research-Cottrell ESPs, it aligns without extensive rewiring, easing upgrades by preserving analog sync loops while enhancing fault tolerance against transients up to 2 kV in vibration-heavy enclosures. In expansive industrial automation deployments, its compact DIN-rail mount and 50/60 Hz adaptability handle thermal swings from -25°C to +70°C, enabling scalable expansions that absorb growing filtration banks without repeaters. By prioritizing adaptive arc quenching and diagnostic relays, the Alstom EP3-E-4-EN bolsters system stability, empowering tighter opacity control and reduced spark rates that directly lifts efficiency, all while curbing the engineering overhead of manual TR tuning in demanding automation landscapes.

When evaluating ESP controllers for redundancy-heavy stacks, the Alstom EP3-E-4-EN warrants consideration for its field density and protocol flexibility, providing the regulation reliability that unifies high-voltage management in EMI-challenged or sync-variable environments without sacrificing response times.

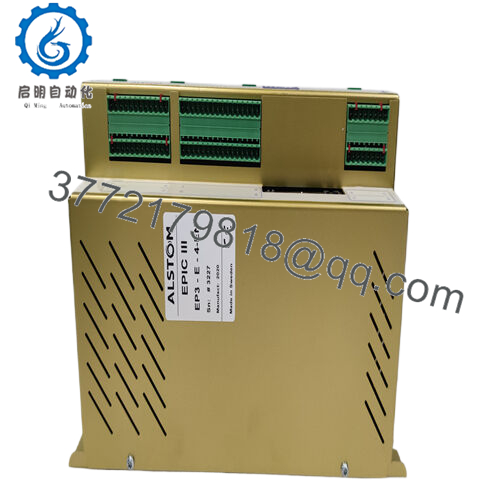

- EP3-E-4-EN

How the Product Works & Fits into a System

The Alstom EP3-E-4-EN functions as a custom controller module in the power management layer of Alstom’s (now GE or Enexco) EPIC III ESP control ecosystem, orchestrating voltage, current, and rapping for up to four fields in precipitator sections. It mounts via DIN-rail or panel in control cabinets, where its core processor handles adaptive PID loops for TR set signals (e.g., 0-10 V or 4-20 mA), enabling arc detection and soft ramping to prevent inrush currents up to 10% per second. This setup supports programmable setpoints via front-panel keys or PC tools, with relays for rapper commands and Modbus/Profibus for SCADA integration, ensuring synchronized fields without phase hunting.

In a typical hierarchy, it draws 100-690 V AC (50/60 Hz) from the ESP bus, interfacing downstream to actuators (e.g., TR sets) and upstream to HMIs for trending, while integrating with synchronizers for hot-sync under 200 ms. It pairs with expansion modules for extended I/O and complies with ISO 14001 for emissions verification, with diagnostics flagging under/over-voltage or arc events via LEDs or bus alerts. Positioned as the orchestration engine between precipitators and grids, the Alstom EP3-E-4-EN streamlines ESP architecture by consolidating regulation in a single unit, where screw terminals facilitate screened cabling in panels—fostering a fault-tolerant pathway that scales with Ethernet/IP overlays, upholding sync precision across topologies without introducing voltage sags or reconfiguration burdens.

| Specification | Details |

|---|---|

| Model Number | EP3-E-4-EN (EPIC III Controller) |

| Brand | Alstom (EPIC III Series) |

| Type | ESP Controller Module (4 Fields) |

| Input Voltage | 100-690 V AC, 50/60 Hz |

| Operating Temp Range | -25°C to +70°C |

| Mounting Style | DIN Rail / Panel |

| Dimensions | 144 x 72 x 120 mm (W x H x D) |

| Weight | 0.5 kg |

| Interface/Bus | Modbus RTU, Profibus |

| Compliance | CE, ISO 14001, RoHS |

| Supported Protocols | Modbus, Profibus, Ethernet/IP |

| Typical Power Draw | 10 W |

Real-World Benefits

Incorporating the Alstom EP3-E-4-EN equips your ESP with regulation stamina that sustains ±1% voltage stability during rapping, quashing the arcing that stresses insulators and stalls filtration in multi-field runs, which in turn refines opacity targets and trims reagent spikes from inefficient sparking. This vigilance shines in auto-transfer configs, where arc quenching parses faults under 100 ms, often halving recovery windows and letting operators focus on emissions forecasting over fault chasing.

Diagnostic outputs further optimize upkeep, with event logs that expose threshold breaches for targeted resets, streamlining audits to quarterly reviews that extend MTBF in monitored precipitators. Its DIN form trims scaling friction too—populating cabinets demands only bus addressing via software, not chassis rewires, which conserves engineering for opacity profiling over hardware hunts. Built for enclosure grit, it withstands 5 g vibrations and 95% humidity with robust relays, buffering surges to lock in long-term safeguarding, keeping your EPIC core adaptive to field surges or ambient shifts gracefully.

Typical Use Cases

In coal-fired boilers, the Alstom EP3-E-4-EN orchestrates TR sets for fly ash capture, where its adaptive PID endures dusty, thermal vaults to enforce critical system uptime and sub-50 mg/Nm³ emissions in continuous process control.

Cement kiln ESPs deploy it for particulate ties, handling fast data cycles amid abrasive, high-vibe holds to synchronize high-reliability rapper syncs.

For steel mill sinter plants, this controller aggregates voltage signals, meeting particulate constraints with Modbus links that enable modular panel growth in expansive I/O vaults.

Compatible or Alternative Products

EP3-E-4-A – Analog variant for non-Ethernet field ties in legacy EPIC III setups.

EP3-G-4-A-EN – Enhanced grid-parallel edition for utility-scale ESP management.

EPIC III Base – Core controller for non-expansion single-field applications.

EP3-E-8-EN – Eight-field counterpart for larger precipitator sections.

Alstom TR Set – Compatible transformer-rectifier for direct voltage regulation.

EP3-SYNC – Synchronizer add-on for multi-field hot-sync enhancements.

GE Enexio ESP Module – Modern successor for upgrading from EP3-E-4-EN systems.

Setup Notes & Maintenance Insights

Before deploying the Alstom EP3-E-4-EN, confirm firmware at version 3.x or later for Modbus integration, and torque terminals to 0.5 Nm to resist vibration loosening—loose fits amplify noise in dynamic precipitators. Balance bus loads under 80% during staging to prevent thermal spikes, and route voltage leads with twisted shielding to cap EMI below 2 mV, especially in cabinets near TR sets.

Sustaining it involves semiannual contact resistance checks at <50 mΩ with a micro-ohmmeter in humid boiler rooms, ensuring snug fits without residue bridging. Poll event logs bimonthly via the front panel or PC tool to trend arc thresholds, addressing drifts over 1% with TR tweaks. Semiannual sync tests under simulated loads validate ramping at 10% s, and archiving config files aids rapid restores. This pragmatic routine aligns with your PM cadence, forestalling faults that unsettle filtration harmony.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626