Description

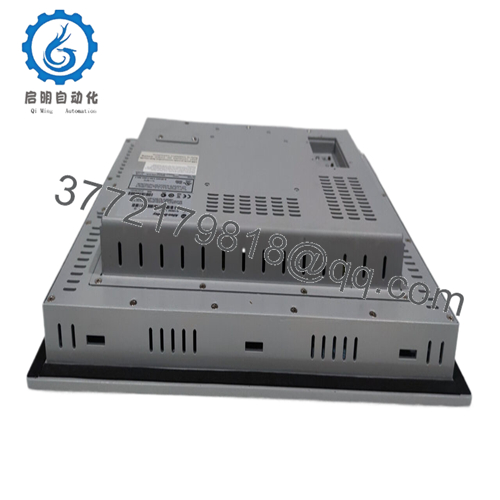

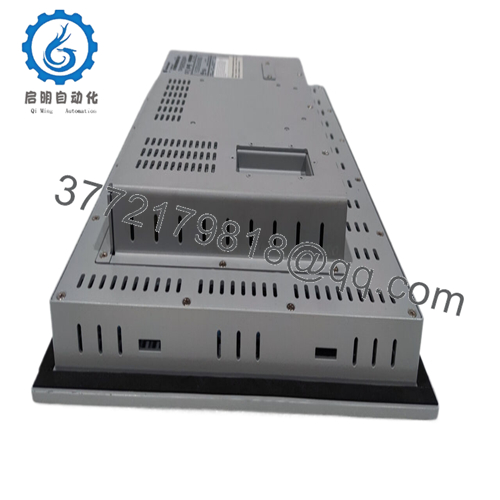

The Allen Bradley 6186M-15PT is a 15 inch industrial touchscreen HMI that seamlessly integrates with Allen Bradley’s FactoryTalk View SE software and a wide range of Rockwell Automation control platforms including ControlLogix and CompactLogix. As the central hub for communication between operators and systems, it enables users to send precise commands, monitor real-time process data in detail, and easily manage system operations.

6186M-15PT

The 6186M-15PT is equipped with a high-performance processor that can handle complex graphical interfaces and large-scale data processing without any problems. Its 15 inch LCD display adopts projected capacitive touch technology, providing a clear, vivid, and responsive user experience. Operators can easily browse detailed process diagrams, adjust parameters, and view historical data using intuitive touch gestures similar to modern mobile devices.

6186M-15PT

Technical specifications:

Model number 6186M-15PT

Brand Allen Bradley

Type 15 inch industrial touch screen HMI

Display screen size 15 inches

Display screen type: LCD with projected capacitive touch screen

Installation method: Panel installation

Interface/Bus Ethernet/IP, PROFINET, Modbus TCP

Compliance CE, UL, cUL

Special function anti glare screen, fanless design, reliable operation in harsh environments

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

6186M-15PT

Main features and advantages:

Its 15 inch large-sized high-resolution display provides a broad field of view for process data, allowing operators to monitor multiple variables simultaneously without the need to frequently switch screens. This enables them to quickly identify trends, anomalies, and potential issues, thereby making faster and wiser decisions. The intuitive touchscreen interface significantly reduces the learning curve for new operators, reduces errors, and speeds up the command execution process. Therefore, productivity has been improved, production cycles have been optimized, resulting in increased output and reduced costs.

The robust structure and wide operating temperature range of this HMI make it suitable for deployment in the most challenging industrial environments, from dusty factories to high-temperature processing plants. Its fanless design eliminates the risk of malfunctions caused by dust and reduces maintenance requirements, ensuring long-term reliable operation. Seamless integration with Rockwell Automation’s control platform and communication protocol simplifies system design, installation, and maintenance, saving time and resources.

The advanced security features of 6186M-15PT are crucial in today’s digitally driven industrial environment. By protecting automation systems from unauthorized access and network threats, it ensures the continuity of critical operations and the integrity of sensitive production data. The ability to customize HMI interfaces using FactoryTalk View SE software enables companies to customize displays and functionalities based on their specific operational needs, providing long-term flexibility and value. Overall, Allen Bradley 6186M-15PT is a reliable and efficient solution that significantly improves the performance, safety, and productivity of industrial automation systems.

6186M-15PT

Application areas:

In the automotive manufacturing industry, it is used for large assembly lines to manage and monitor the operation of multiple robot units, conveyor systems, and quality control stations. Operators can use this HMI to view real-time production data, adjust production parameters according to changes in demand, and promptly troubleshoot to ensure smooth and efficient production.

In the chemical processing industry, precise control of chemical reactions and strict compliance with safety regulations are crucial. This HMI is used to monitor and control variables such as temperature, pressure, flow rate, and chemical concentration. Detailed graphical displays enable operators to visualize process trends, make informed adjustments, and ensure the safe and efficient operation of chemical plants.

In the food and beverage industry,6186M-15PT is used to manage production processes, monitor quality control parameters, and ensure compliance with food safety standards. Operators can use this HMI to control filling machines, packaging equipment, and temperature sensitive storage systems to ensure the quality and consistency of food products. Whether in industries that require high-precision control, real-time monitoring, or strict regulatory compliance, the Allen Bradley 6186M-15PThas been proven to be a versatile and reliable HMI solution.

6186M-15PT

Related products:

6186M-22PT: A 22 inch version with a larger display screen, suitable for applications that require more extensive data visualization and complex control interfaces, such as large control rooms.

6181X-15TPXPDC: Another 15 inch industrial touch screen HMI with different features, suitable for users who prioritize specific aspects such as energy efficiency or certain communication capabilities.

6186M-10PT: A 10 inch variant designed for space constrained environments that require compact and powerful HMI, such as small manufacturing units.

2711P-T15W22D9P-B5A: A 15 inch widescreen HMI with a robust design, suitable for extremely harsh industrial environments that require high durability and resistance to environmental factors.

6186M-15PTX: A model with slightly different specifications, providing users with alternative options within the same product series.

Installation and maintenance:

Before installing Allen Bradley6186M-15PT it is essential to verify that the input voltage of the power supply is completely consistent with the specified range. Choose a suitable panel installation location that is easy for operators to access and provides sufficient protection against environmental factors such as dust, moisture, and overheating. When making wiring connections, carefully follow the provided wiring diagram to ensure proper connection with other components in the automation system. Pay special attention to properly grounding equipment to prevent electrical interference and ensure stable operation.

For continuous maintenance, please regularly use soft, non abrasive fabrics and suitable cleaning solutions to clean the surface of the touch screen to remove dirt, fingerprints, and other contaminants. This helps maintain the responsiveness of the touch screen and the clarity of the display screen. Regularly check the status indicator lights of the HMI to monitor its operation and pay attention to any error codes or warning signals that may indicate communication failures, power abnormalities, or software malfunctions. Check for signs of wear, tear, or loose connections in the power and communication cables. If any damage is found, replace them immediately. It is also crucial to regularly backup the HMI configuration to external storage devices to prevent data loss in the event of hardware failure or software issues. If any technical issues arise during operation, please refer to the comprehensive user manual or contact Rockwell Automation’s technical support team for timely assistance.

A-B related product models:

A-B 2711-T5A5L1

A-B 1326AB-B515E-21-L

A-B 2711-K6C5

A-B Rockwell T8110B

A-B 2711-K5A8

A-B T8480C

A-B 2097-V34PR5

A-B 2711P-T12W22A9P

A-B 6181X-12TPXPDC

A-B 1336-WB110

A-B 1756-L72

A-B 1756-RM2

A-B 41391-454-01-S1FX

A-B 206-00212

A-B 1336-BDB-SP79D

A-B 5069-L350ERMK

A-B 5202-DFNT-MCM4

A-B 1769-L33ERMS

A-B 2711P-T6C20D8

A-B 2094-BM03-M

A-B 2094-BC04-M03-M

A-B 1797-PS1E

A-B 1797-PS1E

A-B 6181P-15A2MW71AC

A-B 80026-529-01-R

A-B 2711P-RP9DK

A-B 6181X-12TPXPDC

A-B 2198-H040-ERS2

A-B 1326AB-B720F-S2K7L

A-B 6186M-17PT

A-B F-4075-R-H04AA

A-B 80190-580-01-R

A-B 80026-524-01-R

A-B 80190-320-03-R

A-B 80190-380-02-R

A-B 80190-580-01-R

A-B 6177R-MMPXP

A-B 81001-451-82

A-B 81001-451-83-R

A-B 81001-451-83-R

A-B MPL-B540K-SJ24AA

A-B 2097-V34PR6-LM

A-B 2097-V34PR6-LM

A-B 817-E2

A-B MPL-B540K-SJ24AA

A-B MPL-B430P-MK22AA

A-B 2711P-K10C4D8

A-B 2711P-K10C4D8

A-B 1756-L73

A-B 2094-BC04-M03-S

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626