Description

In industrial automation environments, where operators need quick, reliable access to machine status and control functions amid the clamor of production floors, engineers frequently deal with interfaces that fall short—clunky keypads that slow responses, monochrome displays that obscure critical data in low-light conditions, or communication silos that hinder real-time PLC integration. The Allen-Bradley 2711-T5A8L1 steps in as a compact, touchscreen-enabled HMI from the PanelView 550 series, delivering intuitive pixel-graphics visualization and direct connectivity to legacy controllers for streamlined process control. Envision a packaging line where shift changes demand instant recipe swaps or alarm acknowledgments—if the interface lags or requires multiple steps, you’d see bottlenecks in throughput or overlooked faults leading to jams and waste. This terminal becomes essential in such high-reliability setups, where its DH+ port ensures seamless I/O signal exchange with PLC-5 or SLC 500 systems, supporting system stability without the need for costly adapters or full overhauls.

The Allen-Bradley 2711-T5A8L1 is a workhorse for mid-sized operations prioritizing operator efficiency, like conveyor sequencing or simple batch monitoring, where its 170 KB runtime memory handles basic trends, alarms, and recipes without overwhelming resources. It’s particularly valuable in dusty or vibration-prone areas, offering a NEMA Type 12/13 enclosure that withstands incidental contact while enabling modular integration via PanelBuilder32 software for custom screens. By incorporating RS-232 for printer outputs, it facilitates audit trails for compliance-heavy tasks, reducing the engineering time spent on custom logging. In facilities with mixed legacy and modern gear, it bridges gaps that could otherwise fragment data flows, aligning with goals of enhanced diagnostics and minimal training curves. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” fit naturally—the Allen-Bradley 2711-T5A8L1 empowers front-line teams to interact confidently, fostering quicker decisions that keep lines moving in environments where every second counts toward uptime.

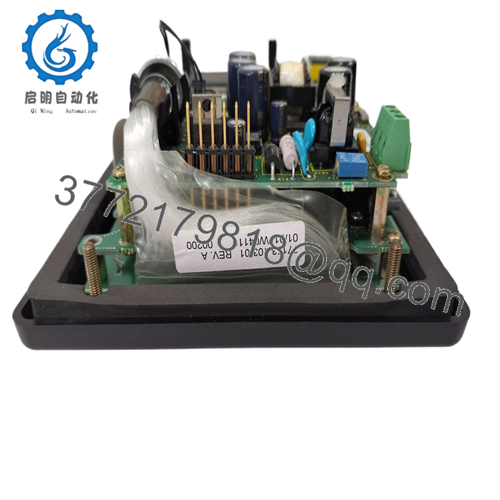

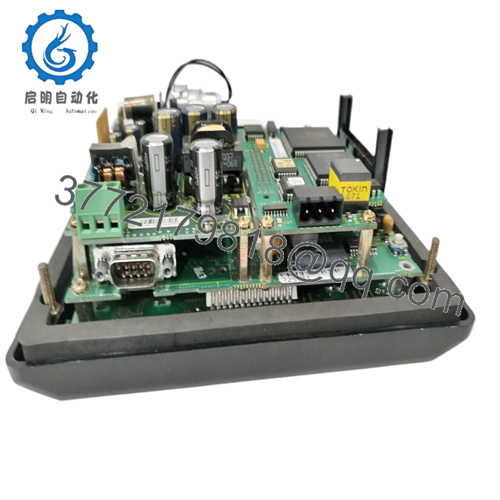

The Allen-Bradley 2711-T5A8L1 mounts via its integrated bezel into panels or enclosures, connecting to the automation stack through its DH+ port for multi-drop networking with Allen-Bradley PLCs over Belden 9463 cable, while the RS-232 serial link handles unidirectional printing to alarm loggers or basic data export. Positioned at the human-interface layer, it polls controller tags—up to 500 words—for displaying status, setpoints, or bit-mapped graphics, with touchscreen inputs translating to direct writes back to the PLC for commands like start/stop or mode selects. This setup integrates with backplane-free architectures, where it stands alone as a dedicated operator station, supporting up to 10 screens with built-in objects for pushbuttons, indicators, and numeric entry without external processors.

In a typical deployment, the terminal’s 256 x 128 monochrome LCD renders crisp, high-contrast icons for at-a-glance reads, with the resistive touchscreen registering finger or stylus taps for precise navigation, even with gloves on. It draws power from a 24 VDC supply, with onboard logic handling event queuing to buffer minor comm drops, and its RS-232 output streams formatted alarm strings for archival. For instance, in a mixing station, the Allen-Bradley 2711-T5A8L1 might show tank levels pulled via DH+, allowing operators to adjust speeds on the fly while printing shift-end summaries— all while maintaining isolation to prevent noise from corrupting PLC scans. This straightforward positioning cuts cabling needs and boosts compatibility with older I/O architectures, letting focus shift to workflow tweaks rather than interface fiddling in the overall process control flow.

- 2711-T5A8L1

| Specification | Details |

|---|---|

| Model Number | 2711-T5A8L1 |

| Brand | Allen-Bradley (Rockwell Automation) |

| Type | PanelView 550 Monochrome Touchscreen Terminal |

| Input Voltage | 18-32 VDC |

| Operating Temp Range | 0 to +50°C |

| Mounting Style | Panel-mount (NEMA 12/13, IP65) |

| Dimensions | 152 x 266 x 106 mm (6 x 10.5 x 4.2 in) |

| Weight | 0.93 kg (2.05 lb) |

| Interface/Bus | DH+ (9-pin), RS-232 (printer) |

| Compliance | UL 508, CSA C22.2, CE |

| Supported Protocols | DH+, DF1 (via RS-232) |

| Typical Power Draw | 18 W |

Selecting the Allen-Bradley 2711-T5A8L1 means outfitting your station with an interface engineered for daily grind, where its monochrome display cuts glare in variable lighting to ensure long-term performance by highlighting alerts without false positives from color bleed or washout. On the floor, this translates to operators spotting overtemp warnings at 10 meters, enabling preemptive cools that avert motor trips and sustain cycles—vital for processes where delays compound into scrap or safety logs.

The terminal’s touchscreen also trims interaction overhead, as gesture-free taps replace key hunts, speeding acknowledgments by seconds per event and easing onboarding for rotating crews, while the DH+ link’s noise immunity reduces comm retries in motor-heavy zones. Maintenance lightens up too: self-diagnostics flag backlight fades via status bits, and replaceable lamps (2711-NL1) swap in minutes without tools, aligning with protocols for sub-hour fixes that keep panels productive. For sites valuing simplicity over bells, the Allen-Bradley 2711-T5A8L1 elevates HMIs from clunky peripherals to responsive allies, bolstering efficiency and compliance without demanding constant tweaks.

In discrete assembly lines, the Allen-Bradley 2711-T5A8L1 visualizes part counts and fault buffers, its DH+ tie-in pulling I/O from SLC 500 PLCs amid oily mists and shakes—high reliability for process control holds firm, ensuring critical system uptime as operators tweak feeds without halting conveyors.

Water utilities deploy the Allen-Bradley 2711-T5A8L1 for pump station overviews, rendering flow trends in damp, low-light vaults where RS-232 prints daily logs; its compact footprint and touchscreen deliver process control clarity, preventing dry-runs through vigilant level checks in remote setups.

Food processing fillers use the Allen-Bradley 2711-T5A8L1 for recipe selectors, interfacing legacy PLCs over DH+ in steamy, washdown bays—its monochrome resilience maintains high reliability, optimizing fills via fast recipe swaps for consistent batches.

2711-T5A9L1 – Keypad/touch hybrid variant for gloved operations in high-precision tasks.

2711-T5A1L1 – RS-232 serial model for basic PLC comms without DH+ needs.

2711-K5A8L1 – Keypad-only counterpart for rugged, non-touch environments.

2711P-RN6 – PanelView Plus 6 retrofit terminal for color upgrades from 2711 series.

2711-K5A5L1 – Compact 5-inch monochrome with DH-485 for SLC/MicroLogix links.

2711-T5A10L1 – Enhanced memory version for more screens and trends.

2711-NL1 – Backlight replacement kit for extending 2711-T5A8L1 display life.

When readying the Allen-Bradley 2711-T5A8L1 for panel cutout, measure the 138 x 250 mm bezel template precisely to avoid misalignment, and confirm DH+ cable (1771-CD) termination with BNC-style connectors for daisy-chain drops under 4000 meters total. Verify supply ripple below 200 mV at 24 VDC to prevent screen flicker, and test touchscreen calibration via PanelBuilder32 before sealing the NEMA enclosure—aim for response under 50 ms per tap. If in humid spots, apply silicone seals around the gasket to hit IP65, and ground the chassis to under 1 ohm for EMI shielding.

For the Allen-Bradley 2711-T5A8L1, routine checks start with weekly status LED scans for RUN/FAULT greens, using a soft cloth to wipe the screen quarterly against fingerprints that dull contrast, especially in greasy areas. Biannually, download runtime logs via RS-232 to a PC for alarm pattern reviews—if comm errors exceed 2%, reseat the DH+ plug; replace the backlight if dimming hits 50% via the 2711-NL1 kit, a 15-minute job with power off. During annual audits, simulate tag faults in PanelBuilder to validate screen refreshes under 1 second, but keep it offline: no live disruptions needed. These grounded steps, per UL 508 guidelines, sustain crisp visuals without pulling panels apart.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626