Description

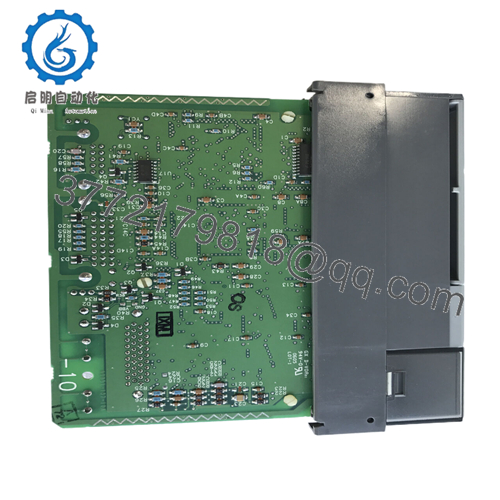

The Allen Bradley 1747-L553 is a cutting-edge programmable logic controller that serves as the nerve center of industrial automation systems. As a high-end product in the Allen Bradley SLC 500 series, it can seamlessly integrate with various input/output (I/O) modules, human-machine interfaces (HMI), and other automation devices. Its core function is to interpret input signals from sensors, switches, and other devices, execute complex control programs, and then send precise output signals to actuators and other devices.

1747-L553

The Allen Bradley 1747-L553 uses ladder diagram programming language, which is familiar and intuitive for industrial automation professionals, facilitating the development, modification, and maintenance of control strategies. What truly sets this PLC apart among engineers and integrators is its enhanced processing capabilities and advanced communication capabilities. It can handle more complex control algorithms and larger amounts of data, making it very suitable for complex automation projects. Whether upgrading existing industrial equipment to meet higher production goals or building state-of-the-art automation systems from scratch, the Allen Bradley 1747-L553 provides the flexibility and performance needed to drive project success.

1747-L553

Main features and advantages:

In terms of functional performance, it has a super fast processor that can execute tens of thousands of instructions per millisecond and respond instantly to constantly changing input conditions. This ensures that even the most dynamic industrial processes can achieve real-time control and monitoring. Its expanded memory capacity allows for the storage of large amounts of control programs, complex data tables, and historical process data, facilitating advanced analysis and process optimization. This PLC supports multiple communication protocols, including Ethernet/IP, DH-485, and remote I/O, and can seamlessly integrate with enterprise level networks, cloud platforms, and other smart devices. This connectivity supports remote monitoring, predictive maintenance, and centralized control, improving overall operational efficiency.

In terms of hardware design, the Allen Bradley 1747-L553 is capable of withstanding the harshest industrial environments. Its sturdy casing provides excellent protection against dust, moisture, electromagnetic interference, and mechanical impact. Modular design facilitates installation and expansion, making it easy to add or replace I/O modules with the development of automation systems. To ensure long-term reliability, the PLC is equipped with comprehensive self diagnostic functions. It will continuously monitor internal components, power supply, and communication links, detect potential faults, and issue alerts to operators in advance to minimize downtime and ensure uninterrupted production.

1747-L553

Technical specifications:

Model 1747-L553

Brand Allen Bradley

Type Programmable Logic Controller

Power supply 120/240 VAC

Processor type: High performance 16 bit

Communication ports Ethernet/IP, DH-485, remote I/O

Working temperature: 0 ° C -60 ° C

Installation method: DIN rail

Certification CE, UL, cUL

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

1747-L553

Application areas:

On the high-speed packaging production line, Allen Bradley1747-L553 is responsible for coordinating the rapid operation of multiple machines. It can precisely control the speed of the conveyor belt, the timing of product placement, and the start-up of the sealing and labeling devices. With its lightning fast signal processing speed, it ensures accurate and efficient packaging of thousands of products per hour, meeting the high demand of the consumer goods market.

In the field of semiconductor manufacturing, nanoscale precision is essential, and this PLC is responsible for monitoring and controlling the complex processes of chip manufacturing. It manages the operation of lithography machines, chemical vapor deposition systems, and etching equipment, adjusts parameters in real-time to ensure the quality and consistency of semiconductor chips.

In heavy machinery production, Allen Bradley 1747-L553is responsible for assembling large components, controlling the operation of cranes, robotic welding machines, and milling machines to ensure the structural integrity and performance of the final product.

Related products:

Allen Bradley 1747-L552- a model with similar performance but slightly lower processing power and memory, suitable for applications with lower requirements. It can be used as an affordable alternative or in combination with 1747-L553 for distributed control systems.

Allen Bradley 1746-IA16- an analog input module that can be perfectly paired with 1747-L553, enabling PLC to receive and process analog signals from sensors such as temperature, pressure, and flow sensors, expanding the system’s monitoring capabilities.

Allen Bradley 1746-OW16- a discrete output module that can be used in conjunction with 1747-L553 to control external devices such as relays, solenoid valves, and motors, achieving precise control of industrial processes. Allen Bradley 2711P-K12C4A8L1- a high-resolution human-machine interface (HMI) that provides operators with an intuitive and detailed interface for monitoring and controlling 1747-L553. It has functions such as touch screen operation and real-time data visualization, which improves user experience and operational efficiency.

Allen Bradley 1747-P4R – a reliable power module designed specifically for the SLC 500 series, ensuring stable and consistent power supply for the 1747-L553 and other connected modules, ensuring system reliability.

Allen Bradley 1788-CN2DN – a protocol conversion module that enables seamless communication between different network protocols, allowing the 1747-L553 to integrate with a wider range of devices and systems and enhance overall connectivity for automation settings.

Installation and maintenance:

When installing Allen Bradley 1747-L553, attention must be paid to details. Before installation, it is necessary to carefully check whether the power supply voltage fully matches the specifications of the PLC. Connecting the wrong voltage may cause immediate damage or abnormal operation of the device. Ensure that the control cabinet not only provides sufficient space for the PLC, but also reserves space for future expansion of I/O modules. Use appropriate installation hardware to securely mount the PLC onto the DIN rail to prevent vibration from affecting its performance. When wiring PLC, it is necessary to strictly follow the detailed wiring diagram to ensure the correct connection of input and output signals, power lines, and communication cables. Pay special attention to properly grounding the PLC to minimize electromagnetic interference.

In terms of maintenance, establish a regular inspection plan to check for signs of wear, breakage, or looseness in the connecting cables. Regularly clean the casing of the PLC to remove dust and debris, which may affect heat dissipation and cause overheating. Regularly backup PLC programs and data to external storage devices to prevent data loss due to hardware failures or unexpected events. Keep the firmware of the PLC at the latest version provided by Allen Bradley, as these updates typically include performance enhancements, security patches, and compatibility improvements to ensure the PLC runs at its best.

A-B related product models:

A-B 2711-T5A5L1

A-B 1326AB-B515E-21-L

A-B 2711-K6C5

A-B Rockwell T8110B

A-B 2711-K5A8

A-B T8480C

A-B 2097-V34PR5

A-B 2711P-T12W22A9P

A-B 6181X-12TPXPDC

A-B 1336-WB110

A-B 1756-L72

A-B 1756-RM2

A-B 41391-454-01-S1FX

A-B 206-00212

A-B 1336-BDB-SP79D

A-B 5069-L350ERMK

A-B 5202-DFNT-MCM4

A-B 1769-L33ERMS

A-B 2711P-T6C20D8

A-B 2094-BM03-M

A-B 2094-BC04-M03-M

A-B 1797-PS1E

A-B 1797-PS1E

A-B 6181P-15A2MW71AC

A-B 80026-529-01-R

A-B 2711P-RP9DK

A-B 6181X-12TPXPDC

A-B 2198-H040-ERS2

A-B 1326AB-B720F-S2K7L

A-B 6186M-17PT

A-B F-4075-R-H04AA

A-B 80190-580-01-R

A-B 80026-524-01-R

A-B 80190-320-03-R

A-B 80190-380-02-R

A-B 80190-580-01-R

A-B 6177R-MMPXP

A-B 81001-451-82

A-B 81001-451-83-R

A-B 81001-451-83-R

A-B MPL-B540K-SJ24AA

A-B 2097-V34PR6-LM

A-B 2097-V34PR6-LM

A-B 817-E2

A-B MPL-B540K-SJ24AA

A-B MPL-B430P-MK22AA

A-B 2711P-K10C4D8

A-B 2711P-K10C4D8

A-B 1756-L73

A-B 2094-BC04-M03-S

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626