Description

In industrial automation, where legacy PLC systems must juggle expanding I/O demands, legacy protocol compatibility, and real-time networking without triggering costly migrations, engineers frequently encounter roadblocks like memory bottlenecks, serial-to-Ethernet translation gaps, or chassis-limited scalability in mid-sized process control setups. The Allen-Bradley 1747-L553 cuts through these as a robust SLC 5/05 processor module, delivering 64K words of user memory to handle sophisticated logic while bridging older field devices to modern Ethernet backbones. Think of a material handling facility where conveyor sequencing relies on DH+ scanners but now needs SCADA integration—if memory overflows or comms falter, you’d risk stalled throughput or data silos that inflate troubleshooting time. This processor proves essential in such high-reliability scenarios, slotting into SLC 500 chassis to extend system life, ensuring I/O signal precision for up to 4096 inputs and outputs without the overhead of full upgrades.

The Allen-Bradley 1747-L553 targets the sweet spot for facilities modernizing incrementally, supporting advanced PLC-5 style instructions for tasks like PID loops or data manipulation that outpace basic SLC models. It’s a mainstay in environments craving modular integration, such as HVAC zoning or small-batch processing, where built-in RS-232 and Ethernet ports enable peer-to-peer messaging with PLC-5, CompactLogix, or ControlLogix peers via protocols like DH+. By incorporating battery-backed CMOS RAM and optional 1747-M13 expansion, it sidesteps data loss during power blips, aligning with goals of enhanced diagnostics through RSLogix 500 programming. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” align perfectly—the Allen-Bradley 1747-L553 sustains legacy architectures with forward-looking connectivity, minimizing disruptions in setups where every scan cycle counts toward operational resilience.

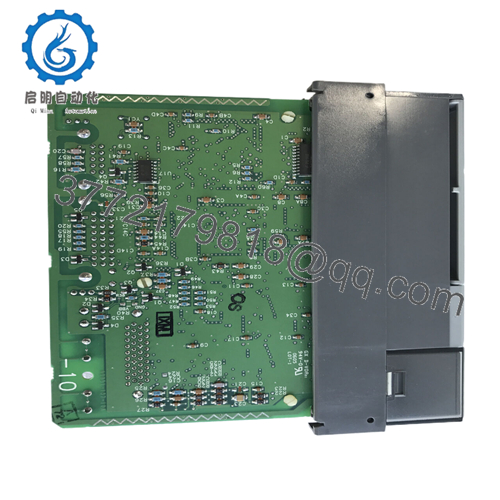

The Allen-Bradley 1747-L553 anchors the SLC 500 modular hardware platform, occupying the fixed slot 0 in 1746 chassis (from 4- to 30-point configurations) to drive the backplane bus, executing ladder logic at up to 1 ms/kHz speeds while polling I/O modules like discrete or analog cards. Positioned as the central processor in the automation stack, it interfaces directly with field devices via its 9-pin RS-232 port for serial protocols (DF1, DH-485) and 10/100 Mbps Ethernet for TCP/IP-based comms, facilitating integration with HMI panels or remote scanners without dedicated gateways. This setup supports distributed architectures, where it can daisy-chain via adapters for DeviceNet, DH+, or Remote I/O, extending reach to 32 chassis in a network while maintaining TMR-like redundancy through peer messaging.

In operation, the processor’s 64K memory (expandable to 128K) stores program files, data tables, and retentive bits, with built-in diagnostics scanning for chassis faults or comm errors, reportable via LEDs or software alerts. For example, in a packaging line, the Allen-Bradley 1747-L553 might sequence servo drives over Ethernet while reading encoder pulses through DH+ scanners, applying floating-point math for position control—all synchronized to avoid jitter in fast data cycles. Its compatibility with RSLogix 500 ladders streamlines configuration, and support for floating-point coprocessors (via add-ons) handles complex calcs without offloading to PCs. This layered approach keeps wiring straightforward, with power drawn from the chassis supply, reducing the need for auxiliary modules and letting engineers layer in expansions like PID instructions for closed-loop precision in the broader process control ecosystem.

- 1747-L553

| Specification | Details |

|---|---|

| Model Number | 1747-L553 |

| Brand | Allen-Bradley (Rockwell Automation) |

| Type | SLC 5/05 Processor Module |

| Input Voltage | 5 VDC (from chassis backplane) |

| Operating Temp Range | 0 to +60°C |

| Mounting Style | Chassis slot 0 (1746 series) |

| Dimensions | 5.7″ x 2.4″ x 3.7″ (145mm x 61mm x 94mm) |

| Weight | 0.45 kg |

| Interface/Bus | RS-232 (9-pin), Ethernet (RJ45), SLC backplane |

| Compliance | UL 508, CE, CSA C22.2 |

| Supported Protocols | Ethernet TCP/IP, DH+, DH-485, DF1, Modbus (via adapters) |

| Typical Power Draw | 800 mA at 5 VDC |

Opting for the Allen-Bradley 1747-L553 equips your setup with a memory-rich core engineered for enduring throughput, where its 64K capacity ensures long-term performance by accommodating growing data tables without frequent purges, letting sequences run flawlessly through voltage dips via battery retention. In the field, this means fewer scan overruns during peak I/O polling—say, coordinating 2000+ points in a conveyor network—yielding consistent process control that curbs rejects and stabilizes energy use, all while the Ethernet port feeds trends to FactoryTalk for anomaly spotting before they halt lines.

The processor’s dual-port design also lightens integration loads, as RS-232 handles legacy modem links alongside Ethernet for web serving, trimming the need for extra converters and engineering hours in mixed-vendor plants. Maintenance streamlines naturally: self-tests on boot flag memory parity errors, enabling quick swaps in hot environments without full chassis power-downs, which aligns with strategies for mean-time-to-repair under 30 minutes. For operations valuing high reliability over flash, the Allen-Bradley 1747-L553 turns a potential legacy drag into a versatile pivot, supporting phased upgrades that preserve investments while unlocking Ethernet-driven efficiencies like remote programming.

In water treatment facilities, the Allen-Bradley 1747-L553 orchestrates pump alternations and level controls via DH+ I/O drops, its Ethernet backbone linking to SCADA for pH trending in corrosive, variable-flow settings—delivering high reliability where process control demands uninterrupted I/O signal handling to avert overflows and sustain critical system uptime.

Food and beverage plants harness the Allen-Bradley 1747-L553 for filler line synchronization, polling sensors over DeviceNet adapters amid washdown humidity and rapid cycles; its 64K memory buffers recipes seamlessly, ensuring precise batching in sanitary environments that prioritize hygiene alongside automation agility.

Discrete manufacturing, like automotive assembly, deploys the Allen-Bradley 1747-L553 for robotic tending, where RS-232 ties to legacy vision systems while Ethernet polls safety interlocks—its robust scan times maintain fast data cycles under dusty, high-vibration loads, bolstering process control for just-in-time workflows.

Allen-Bradley 1747-L543 – 16K memory variant for lighter logic loads, ideal for cost-sensitive expansions.

Allen-Bradley 1747-L552 – 32K step-up with similar ports, bridging small-to-medium program growth.

Allen-Bradley 1747-L551 – Base 8K model for entry-level SLC retrofits in compact chassis.

Allen-Bradley 1746-NIO4I – Analog I/O module add-on for hybrid signal processing with 1747-L553.

Allen-Bradley 1747-SDN – DeviceNet scanner for fieldbus extension in networked setups.

Allen-Bradley 1746-IB16 – 16-point discrete input card to populate chassis alongside the processor.

Allen-Bradley 1747-M13 – 64K memory cartridge for doubling capacity without module swaps.

Before slotting in the Allen-Bradley 1747-L553, confirm chassis firmware compatibility—aim for SLC 500 series OS500 or later via RSLogix 500—to dodge handshake errors, and verify slot 0 clearance with no obstructions, as misalignment blocks backplane contact. Check battery (1747-BA) charge via the status LED; if dim, preload a fresh one to cover the 2-year shelf life, and measure chassis power ripple under 100 mV at 5 VDC to prevent erratic scans. For Ethernet, assign static IPs outside your subnet to avoid conflicts, and ground the shield on RS-232 cables if in noisy zones.

Keeping the Allen-Bradley 1747-L553 humming involves monthly peeks at diagnostic LEDs for RUN/FAULT modes, noting any flickering for memory refresh issues, and using RSLinx to poll error codes quarterly—reset via keyswitch if a latch persists, but log frequencies to track aging. Biannually, during planned outages, reseat the module and test Ethernet ping latency under 10 ms, while swapping the battery if voltage dips below 2.8 V via multimeter. In humid spots, inspect for condensation on ports annually, wiping with ESD-safe cloth. These checks, per Rockwell’s UL 508 playbook, sustain peak logic execution without invasive dives, syncing maintenance to your operational cadence.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626