Description

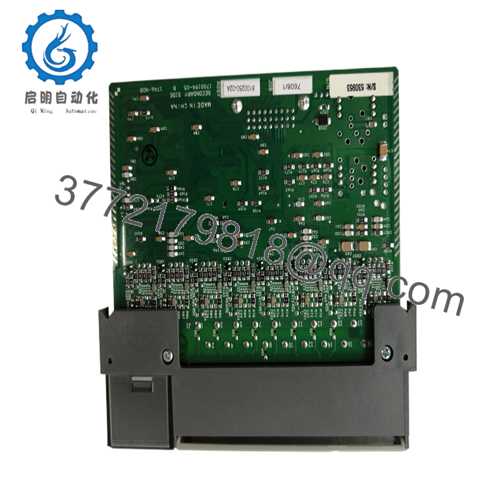

The Allen Bradley 1746-NO8I is a reliable and high-performance non intrinsic safety output module designed specifically for effective control in industrial automation systems. As part of Allen Bradley’s comprehensive SLC 500 I/O module series, it can seamlessly integrate with SLC 500 programmable logic controllers (PLCs) and other components such as human-machine interfaces (HMI) and distributed control systems (DCS).

1746-NO8I

Its main function is to convert the digital signals emitted by the control system into electrical output signals that can drive external devices. The Allen Bradley 1746-NO8I receives instructions from the PLC, processes them, and then sends appropriate electrical signals to relays, solenoid valves, or other output devices. For engineers and system integrators, the value of this module lies in its simplicity and compatibility. It can be easily configured to meet the specific requirements of different applications, whether it is small automation projects or large complex industrial installations. Its compatibility with the SLC 500 platform enables easy integration into existing automation systems, reducing the complexity and cost of system upgrades.

1746-NO8I

Main features and advantages:

In terms of functional performance, it provides fast and reliable signal switching, ensuring that output signals can be transmitted to connected devices in a timely manner, achieving real-time control. With its high output current capacity, it can directly drive various loads in many cases without the need for additional amplifiers, simplifying system design. This module also provides excellent electrical isolation function, protecting the control system from electrical noise and surges, and improving the overall stability and reliability of the automation system.

In terms of hardware design, the Allen Bradley1746-NO8Iis sturdy, durable, and compact in structure. Its durable casing can withstand the harsh tests of industrial environments, preventing the effects of dust, moisture, and vibration. The compact size makes it easy to install in the control cabinet, even in places with limited space.

Compatibility is a major advantage of this module, as it is fully compatible with other modules in the SLC 500 series, enabling seamless expansion and integration of automation systems. In addition, it supports standard industrial communication protocols for easy data exchange with other devices in the network. To achieve long-term reliability, this module has a self diagnostic function. It continuously monitors its internal components and output channels, can detect any faults or abnormalities early, and report to the control system. This proactive approach helps to minimize downtime and ensure the continuous operation of industrial processes.

1746-NO8I

Technical specifications:

Model 1746-NO8I

Brand Allen Bradley

Type: Non intrinsic safety output module

Power supply 24 VDC

Number of output channels 8

Output type: Discrete type

Working temperature: 0 ° C to 60 ° C

Installation method: DIN rail

Certification CE, UL, cUL

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

1746-NO8I

Application areas:

In manufacturing factories, the Allen Bradley 1746-NO8I is used to control various actuators and equipment. It sends electrical output signals to operate conveyor belts, robotic arms, and assembly machinery, ensuring smooth and coordinated production processes. For example, it can precisely control the start and stop of the conveyor belt, achieving accurate transfer of products between different production stages.

In the food and beverage processing industry, this module is used to manage the operation of pumps, valves, and mixers. It ensures that ingredients can be accurately measured, mixed, and transported to maintain product quality and safety standards. On the packaging production line, the Allen Bradley 1746-NO8I controls the movement of packaging materials, the activation of sealing mechanisms, and the operation of labeling machines, simplifying the packaging process and improving production efficiency.

Related products:

Allen Bradley 1746-OB8E – a discrete output module with enhanced functionality that can be used in conjunction with 1746-NO8I in projects that require additional output capability or specific functionality.

Allen Bradley 1746-IM16- an input module with 16 channels that works in conjunction with 1746-NO8I to provide necessary input signals for control systems, while 1746-NO8I is responsible for output and provides a complete I/O solution for automation systems.

Allen Bradley 1746-IV16- Another input module that provides high-speed input functionality, which is very beneficial for applications that require fast signal detection and processing when integrated with the 1746-NO8I.

Allen Bradley 1746-AV4- an analog input module that, when used in conjunction with the 1746-NO8I, can be used for systems involving analog and discrete control, expanding the functionality of automation devices.

Allen Bradley 1746-P2- The power module of SLC 500 system ensures stable power supply for 1746-NO8I and other modules, improving the overall reliability of the system.

Allen Bradley 2711-B6C1A8- a human-machine interface that can be used to configure and monitor the operation of 1746-NO8I, allowing operators to easily adjust output settings and check module status in real-time.

Installation and maintenance:

There are several important considerations when installing the Allen Bradley 1746-NO8I. Before installation, ensure that the power supply voltage is precisely 24 VDC, as any deviation may damage the module or cause it to malfunction. Check if there is enough space in the control cabinet to securely install the module on the DIN rail. Ensure that the DIN rail is properly grounded to prevent electrical interference. When connecting the output wires to the module, please carefully follow the wiring diagram to ensure correct polarity and connect to the appropriate output channel.

During maintenance, regularly check the connecting cables for signs of wear, damage, or loose connections, as these may cause unstable output or system failures. Regularly check the status indicator lights on the module to monitor its operation. If any abnormal indicator lights up, please refer to the user manual for troubleshooting. If applicable, it is also crucial to keep the firmware of the module updated, as new versions of firmware typically include performance improvements, error fixes, and enhanced compatibility with other automation components to ensure that the module can continue to operate at optimal efficiency.

A-B related product models:

A-B 2711-T5A5L1

A-B 1326AB-B515E-21-L

A-B 2711-K6C5

A-B Rockwell T8110B

A-B 2711-K5A8

A-B T8480C

A-B 2097-V34PR5

A-B 2711P-T12W22A9P

A-B 6181X-12TPXPDC

A-B 1336-WB110

A-B 1756-L72

A-B 1756-RM2

A-B 41391-454-01-S1FX

A-B 206-00212

A-B 1336-BDB-SP79D

A-B 5069-L350ERMK

A-B 5202-DFNT-MCM4

A-B 1769-L33ERMS

A-B 2711P-T6C20D8

A-B 2094-BM03-M

A-B 2094-BC04-M03-M

A-B 1797-PS1E

A-B 1797-PS1E

A-B 6181P-15A2MW71AC

A-B 80026-529-01-R

A-B 2711P-RP9DK

A-B 6181X-12TPXPDC

A-B 2198-H040-ERS2

A-B 1326AB-B720F-S2K7L

A-B 6186M-17PT

A-B F-4075-R-H04AA

A-B 80190-580-01-R

A-B 80026-524-01-R

A-B 80190-320-03-R

A-B 80190-380-02-R

A-B 80190-580-01-R

A-B 6177R-MMPXP

A-B 81001-451-82

A-B 81001-451-83-R

A-B 81001-451-83-R

A-B MPL-B540K-SJ24AA

A-B 2097-V34PR6-LM

A-B 2097-V34PR6-LM

A-B 817-E2

A-B MPL-B540K-SJ24AA

A-B MPL-B430P-MK22AA

A-B 2711P-K10C4D8

A-B 2711P-K10C4D8

A-B 1756-L73

A-B 2094-BC04-M03-S

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626