Description

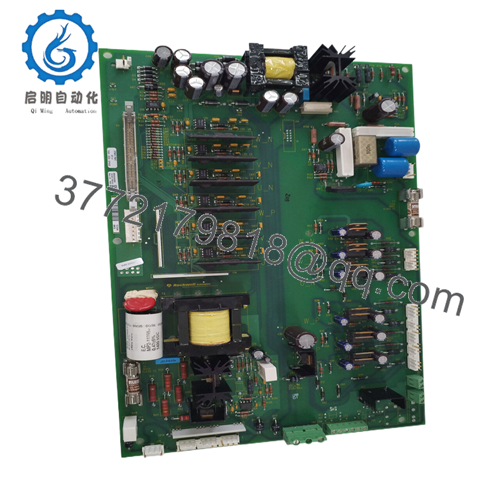

The Allen Bradley 1336-BDB-SP49D has multiple features that make it stand out in the market. In terms of functional performance, it provides high-resolution speed control with an adjustment accuracy of up to 0.1% of the rated speed. This level of precision ensures that the motor operates at optimal efficiency, minimizing energy consumption to the greatest extent possible. Its torque control capability is equally impressive, providing up to 200% of the rated torque at low speeds, which is crucial for applications that require high starting torque, such as heavy machinery. The hardware design of Allen Bradley 1336-BDB-SP49D is robust and compact.

1336-BDB-SP49D

Its sturdy casing can withstand the harsh tests of industrial environments, preventing dust, dirt, and moisture from entering. The compact size makes it easy to install in the control panel, even in limited space. Compatibility is one of its major advantages, as it supports multiple communication protocols including DeviceNet, ControlNet, and EtherNet/IP. This allows it to seamlessly integrate with various control systems and devices, achieving centralized monitoring and control. In terms of long-term reliability, the drive adopts advanced thermal management technology to prevent overheating and ensure stable operation during its extended service life. It also has built-in diagnostic functions that can detect potential issues in advance and reduce the risk of unexpected downtime.

1336-BDB-SP49D

Technical specifications:

Model 1336-BDB-SP49D

Brand Allen Bradley

Type of frequency converter

Power supply 460 VAC, three-phase

Input frequency 50/60 Hz

Output frequency 0-400 Hz

Continuous output current of 49 A

Power rating 25 HP

Installation method: Panel installation

Communication protocols DeviceNet, ControlNet, EtherNet/IP

Certification CE, UL, cUL

Cooling method: forced air cooling

Protection level IP20

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

1336-BDB-SP49D

Application areas:

In automotive factories, the Allen Bradley 1336-BDB-SP49D is used to precisely control the speed and torque of conveyor belt motors, ensuring smooth movement of components on assembly lines. This not only improves production efficiency, but also reduces equipment wear and extends its service life. In the field of material handling, it provides power for cranes and winches, allowing operators to adjust the lifting speed according to the weight and nature of the load, improving safety and operational flexibility.

In the mining industry, harsh conditions are commonplace. This frequency converter can control the motors of ventilation systems, crushers, and conveyors, and maintain stable performance even in dusty, humid, and vibrating environments. Its ability to adapt to different loads and operating conditions makes it an indispensable component in industries that pursue optimized performance and cost savings.

1336-BDB-SP49D

Related products:

Allen Bradley 1336F-BRF-SP2- a smaller capacity drive suitable for applications that require lower horsepower, making it an ideal choice for small motors in packaging machinery.

Allen Bradley 1336E-B020-AA-EN2- designed specifically for basic motor control tasks, providing concise functionality and a simple user interface for easy programming.

Allen Bradley 1336S-B020-AA-EN2- with enhanced safety features, is an excellent choice for applications where operator safety is crucial, such as certain woodworking machinery.

Allen Bradley 1336T-B020-AA-EN2- optimized for high torque applications, providing higher starting and operating torque compared to standard drives, suitable for heavy-duty industrial mixers.

Allen Bradley 1336PLUS II-B020-AA-EN2- Upgraded version, improves energy efficiency and helps businesses reduce electricity bills while maintaining reliable motor control.

Allen Bradley PowerFlex 4M-B020-AA-EN2- designed for general applications, providing an economical and efficient solution for small and medium-sized motors with basic control functions.

Allen Bradley PowerFlex 753-B020-AA-EN2- belongs to a higher-level series with higher performance and advanced communication options, suitable for complex automation systems.

Installation and maintenance:

Before installing the Allen Bradley 1336-BDB-SP49D , careful planning must be carried out. Firstly, please ensure that the input requirements of the power supply and driver are perfectly matched. Incorrect voltage or phase connections may damage the driver and related equipment. Adequate ventilation must be provided around the drive, as forced air cooling systems rely on effective airflow to dissipate heat. When installing, please ensure that the control panel has enough space to accommodate the driver and securely fix it to prevent vibration from affecting its performance.

Regular inspection of electrical connections is crucial during maintenance to ensure they are secure and free from corrosion. Regularly cleaning the drive casing and cooling fan helps maintain optimal heat dissipation. By monitoring the operating parameters of the driver (such as current, voltage, and temperature) through its built-in diagnostic function, any potential issues can be detected early. Keeping the drive firmware updated is also crucial, as firmware updates typically include performance enhancements and error fixes, which can improve its reliability and functionality over time.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626