Description

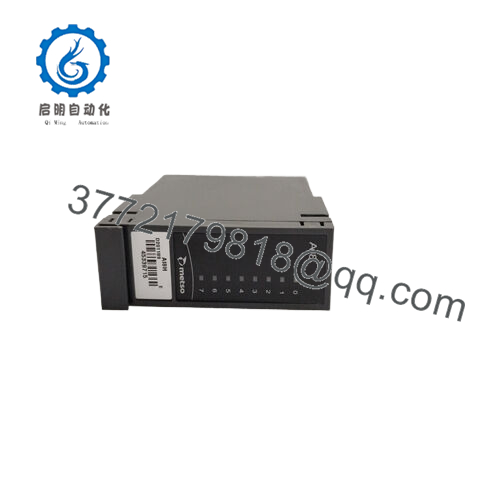

Product Model: AI8H D201189

Product Brand: Metso (Valmet / Metso Automation)

Product Series / Type: HART / Analog Input Module

Key Features (from vendor sources):

- 8 channels for HART / analog input, enabling interfacing with HART-enabled transmitters over 4–20 mA loops.

- Compatible with 4–20 mA HART transmitters; supports two-wire (and possibly four-wire) configurations.

- Offers diagnostics and smart transmitter communication (device status, configuration) along with analog measurement.

- Module is listed in surplus / industrial automation catalogs and marketed as supporting industrial HART loops.

- AI8H D201189

Function & System Role

In process automation systems, analog field devices (e.g. pressure transmitters, flow transducers) often communicate over HART protocol layered onto 4–20 mA current loops. The Metso AI8H D201189 module is designed to bring these HART/analog signals into a DCS or I/O system by converting the 4–20 mA loops into digital values, while also serving as a HART interface—allowing two-way communication (e.g. diagnostics, calibration) with field transmitters.

You would typically find AI8H D201189 in instrumentation racks, I/O chassis or field termination units adjacent to process instrumentation. It pairs with control and logic modules in Metso / Valmet (or compatible) systems to feed analog readings and diagnostic data upstream. This module bridges the analog world and the digital control environment while preserving the HART communication layer.

Because HART devices require communication robustness and diagnostics, this module is more capable than a bare analog input — it needs to support signal integrity, loop powering, and the digital overlay of HART messaging.

Technical Features & Benefits

HART & Analog Integration

- The module supports 8 HART-enabled analog input channels — each channel carries the standard 4–20 mA loop plus HART communication superimposed.

- It handles smart transmitter diagnostics, such as device status, fault reporting, and calibration data retrieval. Some vendor descriptions mention support for device configuration and diagnostics over HART.

- The module is likely to include isolation / filtering / signal conditioning to maintain loop stability and avoid interference with HART signal integrity — though specific isolation specs are not publicly confirmed.

Electrical & Input Characteristics

- It is built to connect to 4–20 mA current loops (standard in HART systems). Vendor listings reference this explicitly.

- Likely supports two-wire loop supply, meaning it provides loop power to the transmitter via the same pair that carries signal and HART messaging (though in many HART modules, separate power feed or auxiliary supply might also be possible).

- The device is often marketed as able to support “0–100%” input range (i.e. full-scale analog range) in some listings.

- Vendors mention supply voltage range of 12–32 VDC for powering the module and the loops.

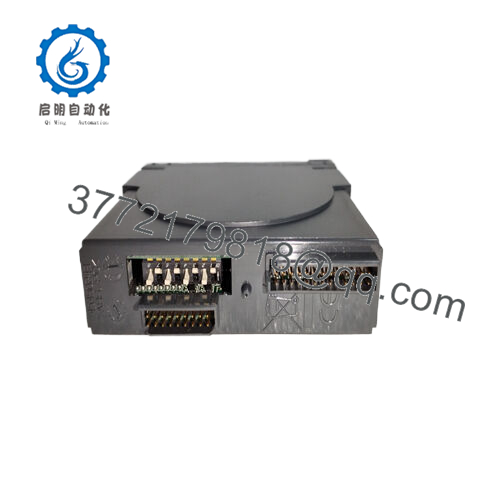

- Mounting style likely fits existing Metso I/O racks or module frames, with the mechanical and electrical interface compatible with the system backplane or bus modules.

Diagnostics & Reliability

- Because HART carries additional meta-data, the module may support detection of loop failure (open / short), transmitter diagnostics, and report those to the control system.

- Vendors often list warranty (1 year) and stock availability in industrial supply networks, which implies a baseline quality assurance.

- Because the module handles both analog and HART signals, the design must ensure that the digital HART pulses do not distort the analog reading or degrade loop performance.

Technical Specifications Table

Below is a spec table based on collected vendor listings. Use this as a reference guide — verify with your hardware:

| Parameter | Value / Range | |

|---|---|---|

| Model | AI8H D201189 | |

| Module Type | HART / Analog Input Module (8 channels) | |

| Input Channels | 8 | |

| Signal Type | 4–20 mA loops with HART overlay | |

| Supply Voltage | 12–32 VDC (module + loops) | |

| Mounting / Interface | Module slot for Metso I/O rack | |

| Diagnostics | Transmitter diagnostics, loop error detection | |

| Warranty | 1 year (vendor) | |

| Application | Process control, instrumentation integration |

Installation & Maintenance Insights

Here are practical suggestions and caveats based on field patterns and module class behavior:

Mounting & Mechanical Fit

- Ensure the module engages fully in its I/O rack or base unit; poor seating may cause HART communication glitches or signal errors.

- Leave ventilation clearance and spacing between modules to reduce heat buildup, which can degrade analog stability and HART interface performance.

- Keep mechanical stress low on connectors — HART modules require stable physical contacts for reliable signal overlay.

Wiring & Loop Design

- Use twisted-pair, shielded cable for each 4–20 mA / HART loop to reduce noise, interference, and cross-talk.

- Terminate shields appropriately (typically at one end) to avoid ground loops.

- Ensure that transmitter loop power is sufficient and stable. If loop supply is weak, HART communication can degrade.

- Avoid long loops with high resistance or inductance that impair HART pulse integrity.

Commissioning & HART Configuration

- After wiring, poll each HART device through the module to confirm communication, configuration, and device status.

- Use known calibration points (e.g. 4 mA, 12 mA, 20 mA) to verify analog reading accuracy.

- Monitor HART signal quality (bit error rates, response delays) to detect wiring or noise issues.

Fault Tolerance & Spares

- Because AI8H D201189 may be less common or legacy, keep a spare if your system depends on HART loop support.

- Label spares clearly with model, revision, and test date.

- Internally test spare modules with dummy HART loops or known devices before deployment.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626