Description

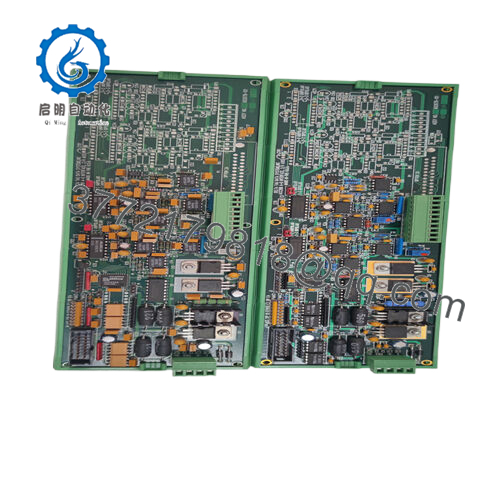

DELTA TAU ACC28B-A-D INTERFACE 24 AXIS functions as a high-performance 24-axis motion control interface module, serving as the critical link between upper-level control systems and a vast array of field devices. It integrates flawlessly into DELTA TAU’s PMAC ecosystem, leveraging advanced processing capabilities to handle the simultaneous coordination of 24 axes while maintaining sub-millisecond latency. The module’s interface design is a standout feature, with a ruggedized architecture that supports multiple signal types—from analog feedback to digital control signals—ensuring compatibility with encoders, servo drives, and sensors from various manufacturers.

ACC28B-A-D INTERFACE 24 AXIS

Unlike generic interface modules, DELTA TAU ACC28B-A-D INTERFACE 24 AXIS is optimized for 24-axis environments, with dedicated signal paths that prevent cross-talk and ensure data integrity even during peak operation. In the automation stack, it sits between the motion controller and field devices, translating high-level motion commands into actionable signals for actuators while relaying real-time feedback from sensors back to the controller, creating a closed-loop system that guarantees precision.

ACC28B-A-D INTERFACE 24 AXIS

Technical specifications:

Model Number ACC28B-A-D INTERFACE 24 AXIS

Brand DELTA TAU

Type 24-axis motion control interface module

Input Voltage 24V DC ±15%

Operating Temp Range -15°C to 75°C (5°F to 167°F)

Mounting Style PMAC backplane mount with optional DIN rail adapter

Dimensions 180mm x 120mm x 40mm (7.1in x 4.7in x 1.6in)

Weight 580g (20.5oz)

Interface/Bus PMAC backplane, 2 x Gigabit Ethernet, 24-axis dedicated ports

Compliance CE, UL 61010, RoHS, IEC 61131-2

Supported Protocols Ethernet/IP, PROFINET, Modbus TCP/IP, CANopen, EtherCAT

Typical Power Draw 9.2W max

contact us:

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: [email protected]

ACC28B-A-D INTERFACE 24 AXIS

Main features and advantages:

The real-world advantages of DELTA TAU ACC28B-A-D INTERFACE 24 AXIS are evident in its ability to streamline 24-axis operations while enhancing reliability. For system integrators, the module’s comprehensive interface support eliminates the need for multiple adapters and converters, reducing wiring complexity by up to 60% in large-scale systems. This not only accelerates installation but also minimizes the risk of connection errors that can disrupt production. For maintenance teams, the module’s built-in diagnostic features—including real-time signal monitoring for each of the 24 axes—simplify troubleshooting, allowing technicians to quickly identify issues such as faulty sensors or loose connections without shutting down the entire system. For production managers, the module’s ability to maintain consistent communication across all 24 axes ensures that complex processes, such as coordinated robotic assembly or multi-axis machining, proceed without deviations, reducing scrap rates and improving overall equipment effectiveness (OEE). Over time, its rugged construction—including conformal coating and vibration resistance (up to 20G)—ensures durability in harsh industrial environments, lowering maintenance costs and extending the module’s operational lifespan.

ACC28B-A-D INTERFACE 24 AXIS

Application areas:

DELTA TAU ACC28B-A-D INTERFACE 24 AXIS excels in applications where 24-axis coordination and reliable interfacing are paramount. In automotive body shops, it controls the 24 axes of robotic welding arms, ensuring each arm moves in perfect synchronization to weld car frames with consistent precision, while its interface handles real-time data from position sensors to adjust for minor variations in part placement. In aerospace manufacturing, the module manages 24-axis CNC machines, translating complex 3D machining instructions into precise movements of cutting tools, with its robust interface relaying feedback from high-resolution encoders to maintain tolerances as tight as ±0.001mm. In logistics automation, it oversees large-scale material handling systems with 24 axes of conveyor belts and robotic sorters, using its interface to coordinate speed and direction across all axes, ensuring efficient product flow in distribution centers. In each of these scenarios, DELTA TAU ACC28B-A-D INTERFACE 24 AXIS proves indispensable for managing the complexity of 24-axis systems.

Related products:

Before installing DELTA TAU ACC28B-A-D INTERFACE 24 AXIS, ensure the PMAC backplane firmware is updated to version 6.0 or higher to support 24-axis communication protocols. Verify that the mounting location provides adequate airflow, as sustained operation above 70°C (158°F) may affect performance—consider forced-air cooling in high-temperature environments.

During installation, use torque screwdrivers to secure the module to the backplane with 0.6 N·m of force to prevent vibration-induced loosening. When connecting field devices to the 24-axis ports, follow the color-coded wiring guide to ensure correct signal mapping, and use only shielded cables to minimize electromagnetic interference. For ongoing maintenance, perform monthly checks of the status LEDs—one per axis—where a steady green light indicates normal operation, and a yellow light signals a weak signal that requires attention. Quarterly, inspect all interface connectors for corrosion or debris, and clean with compressed air if needed. Annually, update the module’s firmware to access the latest protocol support and performance enhancements.

Other product models:

REXROTH R901254695 VT-HNC100-2-3X/N-I-00/000

GE HE693THM666

Triconex 3009

Triconex 3624

Schneider PMC-2/11/04/001/00/03/10/00/10

FIREEYE 95DSS2-1

Tmeic ARND-3110N

smc INR-244-264

GE IC697CPM790

GE IC754VGF15CTD

MacGregor 2141357-804

MacGregor 2141232-802

LAM 839-101612-885

EMC VISATRON VN115/87

Cole Morgan 60WKS-CE240/12PB

TRICONE 3625

TRICONEX 3625

Berger Lahr EXRDM3913/50NEA

TRICONEX 3625

SAACKE HMI10-M REV215

EATON XVS-460-15MP1-1-10

Honeywell HMR2300-D21-485

KONGSBERG RCU502

KONGSBERG RDIOR420

KONGSBERG RSER200-4

KONGSBERG WCC600

GE IS220PDIAH1A

ELAU SM140-30-120-P0-45-M1-B1

GE IS220PDIAH1B

TRICONEX 3625

TRICONEX 3625

Schneider C600/10/1/1/1/00

Triconex Triconex 5201

TRICONEX 9566-810F

TRICONE 3721

TRICONEX 3721

DANIEL DANIEL S600+

schneider XBTGT6340

A-B 1326AB-B720F-21K7-SERIESC

Schneider MICOMP139

PACIFIC SCIENTIFIC BLF2924-10-0-S-017

Rockwell 1794-APBDPV1

Rockwell SST-PB3-SLC

Rusgard LLC GE RS-FS-9001

GE PQMII-C-A

Honeywell IQView8/24

Honeywell IQVIEW4/24

GE F35-W00-VFH-F8L-H6L-M6L-PXX

Yokogawa NFCP100-S05 S3

Woodward 5466-409

TRICONEX 3721

THK TD-020CU-200AC-G15M-5J-N

SIMPLEX 4100-5113

Vibration Monitor AMS3120-A3120/022-000

YOKOGAWA CP451-50S2

HIMA PS1000WR011

YOKOGAWA 3500/22M-01-01-00 288055-01

HONEYWELL FC-SCNT01

Schneider SH30552P11A2000

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626